Exploring Innovations in Marine Bearing Technologies for Enhanced Performance and Reliability

Bearings in Marine Applications An Overview

Bearings play a crucial role in marine applications, serving as essential components that allow for the seamless operation of various machinery and equipment used in maritime environments. Whether on boats, ships, or offshore structures, the right bearings are essential for ensuring safety, reliability, and efficiency. This article explores the importance of bearings in marine settings, the types of bearings commonly used, and the factors that influence their selection and maintenance.

Importance of Bearings in Marine Applications

In the marine industry, bearings facilitate the smooth movement of rotating and oscillating parts, thereby reducing friction and supporting loads. They are integral to various systems, including propulsion, steering, and lifting mechanisms found in ships and boats. For instance, the propeller shaft of a vessel relies heavily on bearings to rotate efficiently against the hull, converting engine power into thrust that propels the vessel forward. Similarly, rudders utilize bearings to pivot effectively, enabling precise steering.

Additionally, marine bearings are often subjected to harsh conditions, such as saltwater exposure, high humidity, and significant temperature fluctuations. As a result, they must be designed to withstand corrosion, wear, and fatigue while maintaining optimal performance. This durability is critical not only for the operational efficiency of marine vessels but also for safety, as bearing failures can lead to catastrophic incidents at sea.

Types of Bearings Used in Marine Applications

There are several types of bearings employed in marine applications, each tailored to specific uses and conditions

1. Plain Bearings Also known as bushings, plain bearings consist of a simple sleeve or cylinder that reduces direct contact between moving parts. These are often used in simple applications where high loads and moderate speeds are present.

2. Rolling Element Bearings Comprising ball or roller elements, rolling-element bearings are widely used in marine engines and propeller shafts. They provide lower friction compared to plain bearings, making them suitable for high-speed applications.

3. Thrust Bearings Essential in applications that require the transfer of axial loads, thrust bearings are used in propeller shafts to handle the forces generated during propulsion.

bearing marine

4. Magnetic Bearings Employed in specialized applications, magnetic bearings use magnetic levitation to support rotating shafts without physical contact, resulting in minimal wear and friction. They are advantageous in high-speed and high-precision environments, though they require sophisticated control systems.

5. Composite Bearings These bearings often consist of a combination of materials, such as polymer and metal, providing enhanced corrosion resistance and low friction properties. They are particularly suited for environments where traditional materials would degrade quickly.

Selection and Maintenance of Marine Bearings

Choosing the right bearing for a marine application involves several considerations

- Load Capacity It's crucial to determine the load requirements of the application to select a bearing that can handle the expected forces without failure.

- Speed The operating speed of the machinery affects bearing selection. Higher speeds may necessitate rolling-element bearings for reduced friction.

- Environmental Conditions Bearings must be suited for the marine environment, where exposure to saltwater and other corrosive elements can lead to premature failure. Using materials resistant to corrosion, such as stainless steel or specially formulated plastics, is essential.

- Maintenance Regular inspections and maintenance are vital to prolonging the lifespan of marine bearings. This includes lubrication, checking for signs of wear or corrosion, and ensuring proper alignment.

Conclusion

Bearings are indispensable components in the marine industry, underlining the importance of proper selection and maintenance. As maritime technology continues to evolve, advancements in bearing design and materials will further enhance their performance and durability, ensuring that marine operations remain safe and efficient. By understanding the significance of bearings and their various types, marine operators can make informed decisions that contribute to the longevity and reliability of their vessels and equipment.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

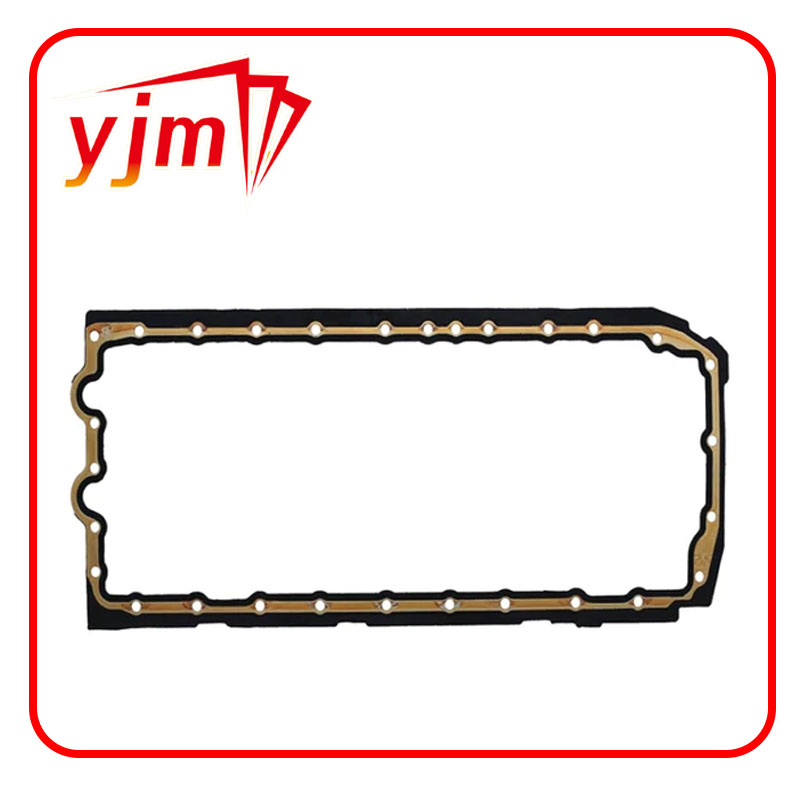

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories