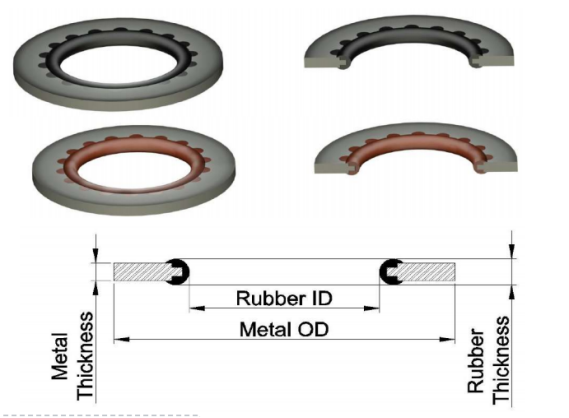

front crankshaft seal

From an authoritative perspective, industry standards emphasize the importance of using Original Equipment Manufacturer (OEM) parts for replacements. OEM seals are designed to the exact specifications of the original component, guaranteeing compatibility and performance. This trusted recommendation aligns with extensive research proving that generic or substandard parts, though cheaper, often lead to recurrent failures and additional complications, thereby undermining the vehicle's operational integrity. Trustworthiness in the selection process is further bolstered by testimonials and case studies that highlight the difference quality makes in back crankshaft oil seal longevity and efficiency. Real-world anecdotes affirm that vehicles serviced with adherence to these best practices consistently exhibit reduced leakage incidents and better overall engine health. Incorporating these insights into a comprehensive understanding of the back crankshaft oil seal underscores the need for both attention to detail and commitment to quality. Both are essential to maintaining an engine's peak performance and reliability. Whether one is a seasoned mechanic or a vehicle owner with a keen interest in automotive health, recognizing the significance of the back crankshaft oil seal is indispensable. It is a testament to the seamless operation of the countless moving parts that comprise an engine, and a reminder of the expertise and precision inherent in its upkeep. This ensures that vehicles remain functional over time, prolonging their service lives in an environmentally and economically sustainable manner.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories