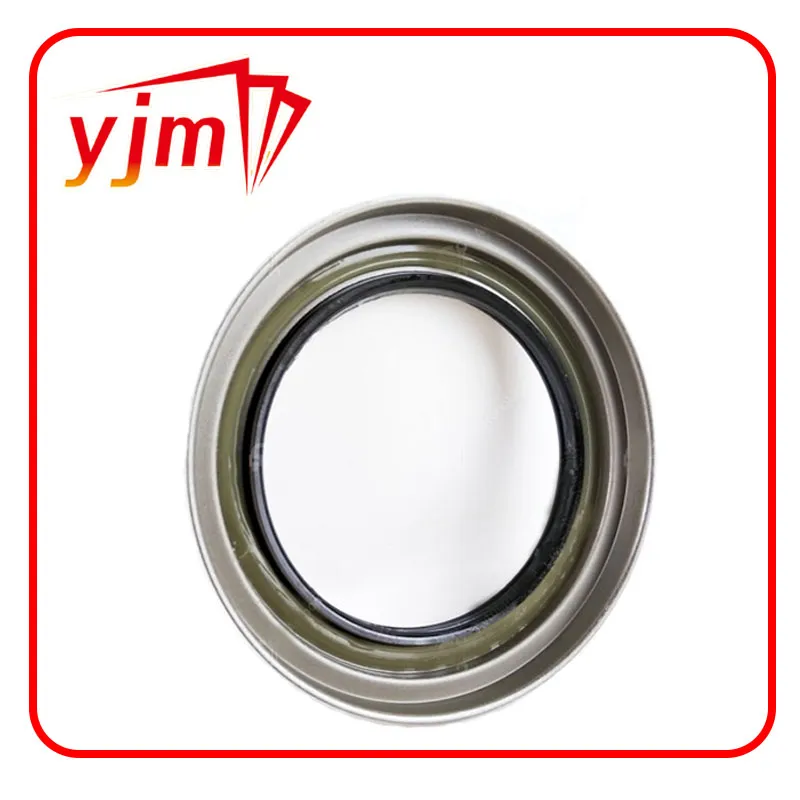

axle output shaft seal

Understanding Axle Output Shaft Seals An Essential Component for Vehicle Longevity

In the complex machinery of vehicles, every component plays a critical role in ensuring smooth operation and longevity. Among these components, the axle output shaft seal might not be the most glamorous part of your vehicle, but its importance cannot be overstated. This article delves into the functions, types, and maintenance of axle output shaft seals, highlighting their essential nature in automotive performance.

What is an Axle Output Shaft Seal?

An axle output shaft seal is a circular component typically located at the axle’s output shaft, which is an essential part of the vehicle's drivetrain. This seal is designed to prevent the leakage of lubricants, such as gear oil or differential fluid, from the axle housing while also keeping external contaminants, like dirt and water, from entering the axle assembly. This dual function is crucial in maintaining the integrity and functionality of the axle and ensuring that the vehicle operates without issues.

Functions of Axle Output Shaft Seals

1. Leak Prevention The primary function of an axle output shaft seal is to prevent oil leakage. A well-functioning seal ensures that the lubrication remains contained within the axle assembly, reducing the risk of wear and tear caused by insufficient lubrication. 2. Contaminant Protection By sealing the axle, it protects the internal components from contaminants. Dirt, water, and debris can cause severe damage to the axle assembly, leading to premature failure if allowed to enter.

3. Noise Reduction Seals also contribute to reducing noise from the drivetrain. A compromised seal can lead to increased noise levels, affecting the overall driving experience.

Types of Axle Output Shaft Seals

There are several types of axle output shaft seals, primarily categorized based on the materials used and their specific application within the vehicle

axle output shaft seal

1. Rubber Seals Common in many vehicles, these seals offer good flexibility and are resistant to oil and temperature variations. They are suitable for standard applications.

2. Lip Seals These seals have a lip that makes contact with the rotating shaft, providing an effective barrier against fluid leakage. They are often used in high-performance applications where pressure and contact with contaminants are more significant concerns.

3. Metal Cased Seals For heavy-duty applications, metal cased seals offer robust protection and durability. These are usually found in trucks and off-road vehicles where the working conditions are more severe.

Maintenance and Replacement

Proper maintenance of axle output shaft seals is crucial for vehicle longevity. Regular inspections can help identify early signs of wear, such as fluid leakage around the axle area. If a seal fails, it can lead to costly repairs not only for the seal itself but also for the entire axle assembly due to potential damage from fluid loss.

Replacement of a damaged axle output shaft seal should be carried out with due diligence. It typically involves draining the axle fluid, removing the old seal, cleaning the surface, and installing a new seal properly to ensure a good fit.

Conclusion

Axle output shaft seals may be small components, but they play a significant role in the overall health of a vehicle's drivetrain. By understanding their function and maintaining them properly, vehicle owners can ensure a smoother driving experience and extend the lifespan of their automobiles. Regular inspection and timely replacement of these seals can save money and prevent unnecessary repairs, making them a crucial aspect of vehicle maintenance.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories