Replacement and Maintenance of Axle Output Shaft Seals for Optimal Performance

Understanding Axle Output Shaft Seals Importance, Functions, and Maintenance

When it comes to automotive engineering, components like axle output shaft seals play a crucial role in ensuring the efficiency and longevity of a vehicle's drivetrain. This article delves into the significance of axle output shaft seals, their primary functions, and tips for maintenance.

What is an Axle Output Shaft Seal?

An axle output shaft seal is a critical component located at the ends of the axle shafts, where they connect to the differential or transmission. Its primary purpose is to provide a barrier that prevents lubricant from leaking out while also keeping dirt, water, and debris from entering the fluid system. This sealing mechanism is essential for maintaining the health of the vehicle's drivetrain.

Importance of Axle Output Shaft Seals

1. Fluid Retention One of the primary roles of the axle output shaft seal is to retain lubricant within the axle housing. Proper lubrication is vital for reducing friction and wear between moving parts, thereby improving the efficiency and lifespan of the drivetrain.

2. Contaminant Prevention Seals prevent external contaminants such as dirt, mud, and moisture from infiltrating the axle assembly. Allowing these elements to enter can lead to significant damage, including accelerated wear of gears and bearings.

3. Cost-Effectiveness Regular maintenance and timely replacement of these seals can prevent more extensive damage to the axle assembly and other related components, ultimately saving vehicle owners a significant amount of money in repairs.

Functions of Axle Output Shaft Seals

Axle output shaft seals perform several essential functions

- Sealing The primary function of the seal is to close off the gap between stationary and moving parts. It maintains the integrity of the lubricant within the system. - Pressure Maintenance These seals also help maintain appropriate pressure levels within the axle assembly. This pressure is critical for proper lubrication and functioning of internal components.

- Temperature Regulation By keeping contaminants out and preventing lubricant leakage, seals assist in regulating the temperature within the axle, helping avoid overheating that could lead to failure.

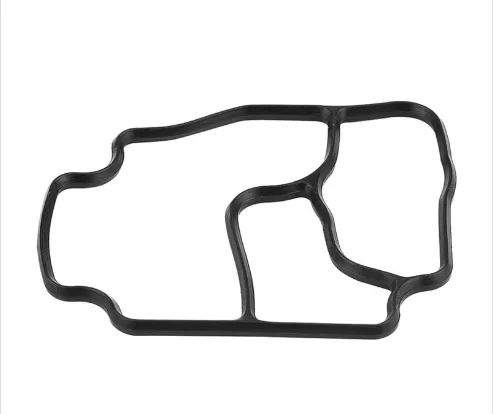

axle output shaft seal

Signs of Wear and Failure

Recognizing the signs of a failing axle output shaft seal is crucial for maintaining the health of your vehicle

- Fluid Leaks One of the most obvious signs of seal failure is an oil leak near the axle assembly. If you notice puddles beneath your vehicle, it may indicate a need for seal replacement.

- Unusual Noises A failing seal may lead to insufficient lubrication, causing increased wear on gears and bearings, leading to grinding or whining noises.

- Contamination If dirt or moisture is present in the axle fluid, it may suggest that the seal is compromised. Regular inspection of the fluid can help detect such issues early.

Maintenance Tips

1. Regular Inspections Periodically check the condition of the axle output shaft seals during routine maintenance. Look for signs of wear, cracks, or leaks.

2. Fluid Checks Monitor the level and condition of the lubricant within the axle assembly. If you notice a decrease in fluid levels, investigate potential leaks.

3. Professional Servicing If you suspect that your axle output shaft seals are failing, seek professional automotive service. A qualified mechanic can safely replace the seals and ensure your vehicle operates smoothly.

Conclusion

Axle output shaft seals may be small components, but their function is vital for the overall performance and longevity of your vehicle's drivetrain. By understanding their importance, recognizing the signs of wear and failure, and adhering to proper maintenance practices, vehicle owners can ensure a more efficient and reliable driving experience. Remember, a proactive approach to vehicle maintenance goes a long way in safeguarding against costly repairs down the road.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories