Understanding Axle Grease Seals and Their Importance in Vehicle Maintenance

Understanding Axle Grease Seals Importance and Maintenance

Axle grease seals are crucial components in the automotive and heavy machinery industries. They play a vital role in ensuring the proper functioning of vehicles by preventing the escape of lubricating grease and the entry of contaminants into the axle housing. Understanding the importance of these seals, their working principles, and maintenance practices can greatly enhance the longevity and efficiency of your vehicle.

The Role of Axle Grease Seals

Grease seals are designed to preserve the integrity of the lubrication system in an axle. The primary function of axle grease seals is to contain the lubricant (grease) within the axle assembly, thereby reducing friction between moving parts. When properly sealed, they prevent dirt, moisture, and other contaminants from entering the axle, which can lead to premature wear or mechanical failure.

Without effective grease seals, the grease can leak out, leading to insufficient lubrication of the bearings. This can cause overheating, increased wear rates, and eventual breakdown of the axle components. Additionally, contaminated grease can lead to corrosion and damage to the axle, greatly impacting the vehicle's performance and safety.

Types of Axle Grease Seals

Grease seals come in various types and designs, depending on the application and requirements. Some common types include

1. Standard Lip Seals These are the most commonly used grease seals. They feature a flexible lip that provides a tight fit against the axle shaft, preventing grease from leaking out while also keeping contaminants out.

2. Double Lip Seals These seals include two sealing lips, providing an extra layer of protection against dirt and moisture. They are often used in more demanding applications where exposure to contaminants is higher.

3. Spring-loaded Seals These seals incorporate a spring that applies tension to the lip, ensuring a reliable seal even in the face of vibration or changes in temperature.

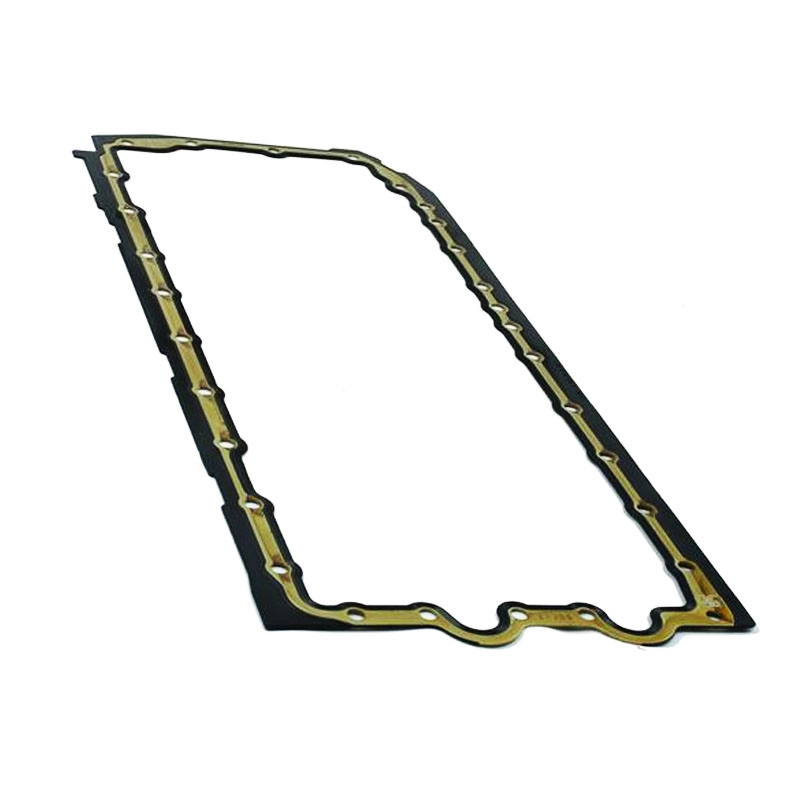

axle grease seal

4. Hard-Backed Seals Designed for heavy-duty applications, these seals have a rigid backing that provides added durability and resistance to deformation.

Maintaining Axle Grease Seals

Proper maintenance of axle grease seals is essential for their longevity and effectiveness. Here are some key practices

1. Regular Inspections Routine checks can help identify issues like leaks or signs of wear. If you notice any grease accumulating around the axle area, it may indicate that the seals have failed.

2. Check for Contaminants Ensure that the seals are free from dirt and debris, as this can compromise their sealing ability. Regular cleaning around the axle area can help maintain the integrity of the seals.

3. Proper Installation When replacing grease seals, ensure they are installed correctly. A misaligned seal can lead to premature failure. Follow manufacturer guidelines for installation procedures.

4. Use Appropriate Lubricants Always use the recommended grease type for your specific application. Using the incorrect lubricant can degrade the seal material and impact seal performance.

5. Replacement Timing Grease seals do wear out over time. It is essential to replace them at the recommended intervals or when signs of wear are present to prevent damage to the axle components.

Conclusion

Axle grease seals are a small but critical component in the operation and maintenance of vehicles. They protect key parts from wear and damage by maintaining the integrity of the lubrication system. By understanding their function, types, and maintenance practices, vehicle owners can ensure their systems operate efficiently and effectively, prolonging the lifespan of their vehicles and enhancing safety on the road. Regular inspections and timely replacements can save you from costly repairs and extend the life of your axle components, making axle grease seals an integral part of vehicle maintenance.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories