Choosing the Right Dust Seal for Your Axle Maintenance Needs

Understanding Axle Dust Seals Importance and Maintenance

In the world of automotive mechanics, axle dust seals play a crucial yet often overlooked role in ensuring the longevity and efficiency of vehicles. These seals are designed to prevent dust, dirt, and other contaminants from entering the axle housing, primarily safeguarding the bearings and lubricants critical for vehicle performance. In this article, we'll delve into the significance of axle dust seals, their construction, common issues associated with them, and some best practices for maintenance.

What are Axle Dust Seals?

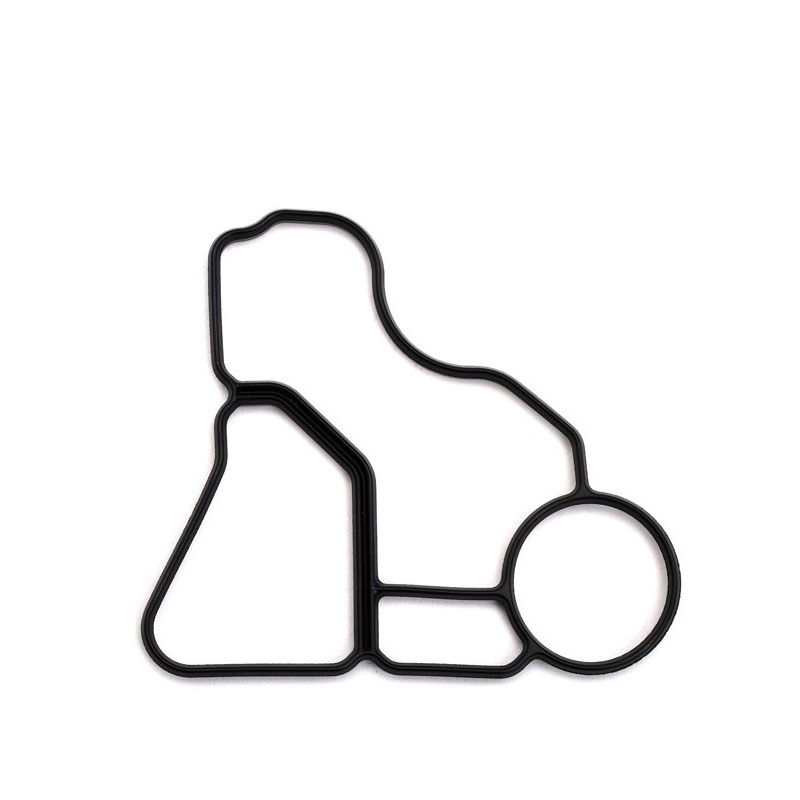

Axle dust seals are typically made from durable materials such as rubber or synthetic compounds. They form a protective barrier at the ends of the axle, where the axle shaft protrudes from the differential or wheel hub. The primary function of these seals is to keep the lubricating grease or oil contained within the axle assembly while blocking harmful debris and environmental elements from infiltrating the internal components. This protective function is vital, as a clean and well-lubricated axle is essential for smooth operation and minimal friction.

The Importance of Axle Dust Seals

The significance of axle dust seals can be appreciated by examining their role in preventing axle failure. Without these seals, contaminants can easily enter the axle and degrade the lubricants, leading to accelerated wear and tear on the axle bearings. Potential issues include overheating, increased friction, and ultimately, the risk of severe axle damage or failure. Such failures not only pose safety risks but can also lead to costly repairs and downtime.

Moreover, maintaining the integrity of the axle dust seal can significantly enhance the overall performance of the vehicle

. A well-functioning axle contributes to better handling, superior handling performance, and improved fuel efficiency. Therefore, ensuring that these seals are in optimal condition is a simple yet effective way to maintain vehicle performance.axle dust seal

Common Issues with Axle Dust Seals

Despite their importance, axle dust seals are not immune to wear and tear. Over time, exposure to harsh environmental conditions, such as extreme temperatures, road salt, and debris, can cause these seals to crack, harden, or deform. Signs of a deteriorating axle dust seal may include visible cracks, grease leakage, or abnormal noise emanating from the axle area.

If left unaddressed, a failing dust seal can result in grease loss, allowing dirt and moisture to accumulate inside the axle assembly, ultimately leading to bearing failure. Therefore, it is imperative to regularly inspect the seals for any signs of wear, especially during routine vehicle maintenance checks.

Maintenance Best Practices

To ensure the longevity of axle dust seals, regular inspection is key. Vehicle owners should include the axle seals in their routine check-ups, particularly during oil changes or major repairs. If any damage is noted, replacing the seal promptly can save significant future repair costs.

Additionally, ensuring that the axle assembly is correctly lubricated can help reduce the wear on the dust seal. The right type of lubricant can create an effective barrier against contaminants while facilitating smooth movement of the axle.

In summary, axle dust seals may be small components, but their role in vehicle performance is indispensable. By understanding their significance and keeping up with regular maintenance, vehicle owners can ensure that their axles operate efficiently and remain protected from the elements. So the next time you’re under the hood or inspecting your vehicle, remember that these unsung heroes deserve your attention and care.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories