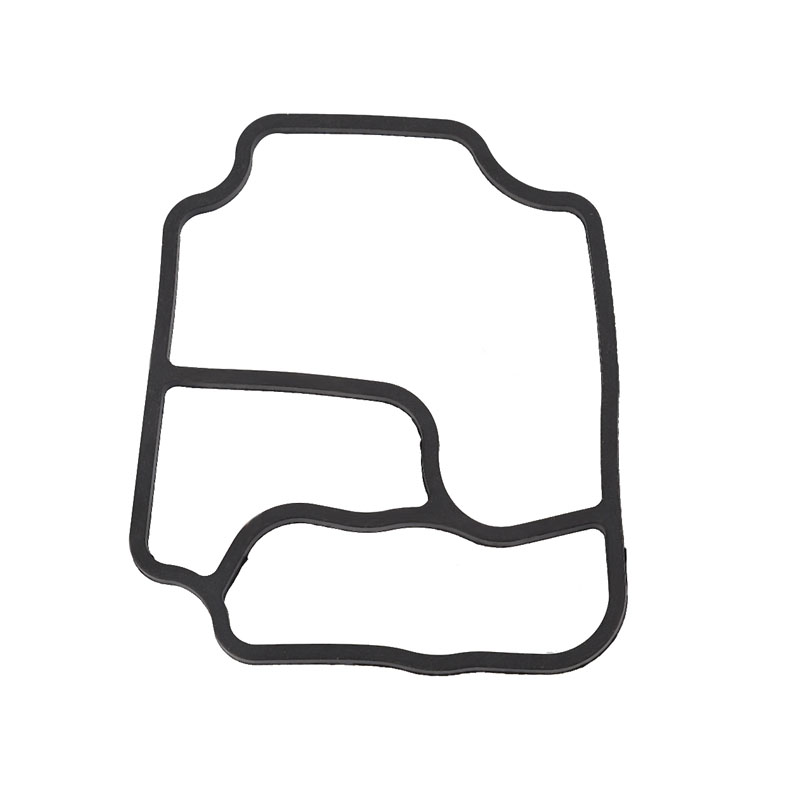

axle bearing seal

Understanding Axle Bearing Seals Importance and Maintenance

Axle bearing seals are essential components in automotive and heavy machinery applications, playing a critical role in maintaining the integrity of the axle system. These seals serve to protect the bearings from dirt, moisture, and contaminants while retaining the lubricant necessary for their optimal function. Understanding the significance, types, and maintenance of axle bearing seals is vital for anyone involved in vehicle maintenance or repair.

Importance of Axle Bearing Seals

Bearings in vehicles experience significant stress due to the loads they carry and the speeds they operate at. Axle bearing seals are designed to prevent the ingress of external contaminants like dirt, dust, and water that can deteriorate bearing performance. These seals also retain lubricants, ensuring that bearings operate smoothly without excessive friction. When axle bearing seals fail, it can lead to premature bearing wear, increased friction, overheating, and even catastrophic bearing failure, which can compromise vehicle safety.

Moreover, the condition of axle bearing seals can directly impact fuel efficiency. Worn or damaged seals can lead to lubricant leakage, which means additional friction in the axle system. This increased friction can lead to higher energy consumption, leading to inefficient fuel usage and increased operational costs, especially in larger machinery.

Types of Axle Bearing Seals

Axle bearing seals come in various designs and materials, each suited for specific applications

. The most common types include1. Lip Seals These seals have a flexible lip that presses against the shaft to prevent the escape of lubricant and the entry of contaminants. Lip seals are commonly used in passenger vehicles due to their effective sealing capabilities and simple installation.

2. O-Ring Seals Often used in applications where space is limited, O-ring seals consist of a circular rubber ring that fits into a groove. They provide a reliable seal but may require careful handling during installation to avoid pinching or twisting.

3. Labyrinth Seals These are complex seals designed with multiple interlocking paths that make it difficult for contaminants to reach the bearings. Labyrinth seals are typically used in heavy-duty applications where extreme environments are common.

axle bearing seal

4. Magnetic Seals Magnetic seals use magnetic forces to create a barrier against contaminants. These seals are particularly useful in high-speed applications, providing a high level of protection and extending service life.

Maintenance of Axle Bearing Seals

Regular maintenance of axle bearing seals is essential for ensuring their longevity and effectiveness. Here are some key maintenance tips

1. Routine Inspections Periodically check the condition of axle bearing seals during vehicle maintenance. Look for signs of wear, cracking, or deformation, which could indicate that replacement is necessary.

2. Cleanliness Ensure that the area around the axle and seals is clean. Dirt and debris can compromise seal integrity and lead to contamination of the bearings.

3. Lubrication Ensure that the axle bearing seals are adequately lubricated. While the seals prevent lubricant leakage, they should not be overly saturated, as this can lead to seal damage.

4. Proper Installation Proper installation of axle bearing seals is crucial. Follow manufacturer guidelines closely to avoid damaging seals during the installation process.

5. Environmental Considerations Be aware of the operating environment. For vehicles used in extreme conditions, consider upgrading to heavy-duty seals designed to withstand harsher elements.

Conclusion

Axle bearing seals are small components with a big impact on vehicle operation and safety. By understanding their importance, types, and maintenance routines, vehicle owners and operators can prevent costly repairs and ensure the longevity of their axle systems. Whether you are a car enthusiast, a professional mechanic, or a heavy machinery operator, attention to the condition of axle bearing seals will contribute significantly to the efficiency and reliability of the vehicles you work with. Regular checks and maintenance can go a long way in protecting your investment and ensuring smooth operation for miles to come.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories