Understanding the Function and Importance of Axial O-Rings in Mechanical Seals

The Importance of Axial O-Rings in Modern Engineering

In the realm of mechanical design and engineering, ensuring the integrity of a system's seals is vital. This is where axial O-rings come into play, providing an effective solution for a myriad of applications. An axial O-ring is a circular sealing component specifically designed to fit into a designated groove, creating a seal when compressed between two surfaces. Their design and functionality have made them one of the most popular choices for sealing applications across various industries, including automotive, aerospace, and industrial machinery.

What is an Axial O-Ring?

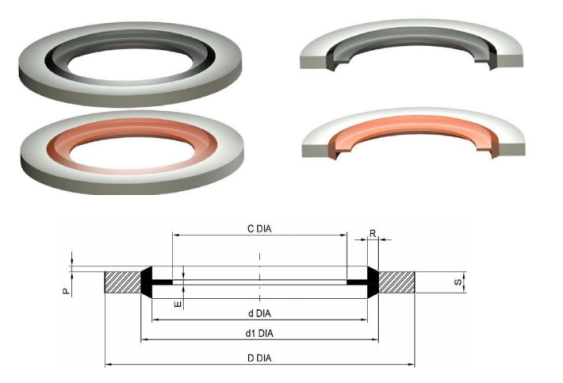

An O-ring is a doughnut-shaped elastomeric ring, usually made of rubber or synthetic materials. The term axial refers to the orientation in which these O-rings are installed—typically placed between two flat surfaces, so that the sealing is achieved along an axis. When a compressive force is applied, the O-ring deforms to fill any gaps between the sealing surfaces, effectively preventing the escape of gases and fluids.

Materials and Design Features

Axial O-rings can be made from a variety of materials to suit specific applications, including nitrile rubber (NBR), fluorocarbon (FKM), and silicone. Each material offers distinct advantages; for example, nitrile is excellent for petroleum-based fluids, while fluorocarbon is ideal for high-temperature and chemical resistance applications.

Moreover, the design of axial O-rings is crucial for their performance. Factors such as cross-sectional diameter, groove dimensions, and compression set must be carefully considered during design. Proper selection ensures optimal sealing performance and longevity, helping to avoid costly leaks or failures.

Applications Across Industries

The versatility of axial O-rings means that they are utilized in an extensive range of applications. In the automotive industry, they help prevent oil leaks in engines and transmissions. In aerospace, they are essential for maintaining the integrity of fuel systems and hydraulic applications, where any failure can have catastrophic consequences.

axial o ring

Moreover, axial O-rings play a key role in industrial settings, such as in pumps and hydraulic cylinders. Their ability to withstand varying pressures and temperatures without losing their sealing capabilities makes them invaluable in such environments.

Advantages of Using Axial O-Rings

One of the main advantages of axial O-rings is their simplicity and cost-effectiveness. Compared to other sealing solutions, O-rings are easy to install and replace, reducing the downtime during maintenance. Furthermore, the diverse range of materials available means that they can be tailored to meet the specific demands of an application.

Another key advantage is their ability to provide a reliable seal over a large pressure range. Axial O-rings can handle not only static sealing but also dynamic sealing in rotational and reciprocating applications, which further broadens their usability.

Challenges and Considerations

Despite their numerous advantages, axial O-rings can also present challenges if not properly designed or maintained. Issues such as inadequate groove size, incorrect material selection, or insufficient compression can lead to seal failure. Therefore, careful engineering and regular maintenance checks are essential to ensure optimal performance.

Conclusion

In conclusion, axial O-rings are a fundamental component in many mechanical systems, providing reliable sealing solutions across various industries. Their simple design, coupled with the ability to withstand diverse operating conditions, has made them an indispensable tool for engineers. As technology continues to evolve, the materials and design methods for axial O-rings will likely advance, paving the way for even more efficient and effective sealing solutions in the future. By understanding their importance and challenges, designers and engineers can harness the full potential of axial O-rings, driving innovation and performance in the engineering landscape.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories