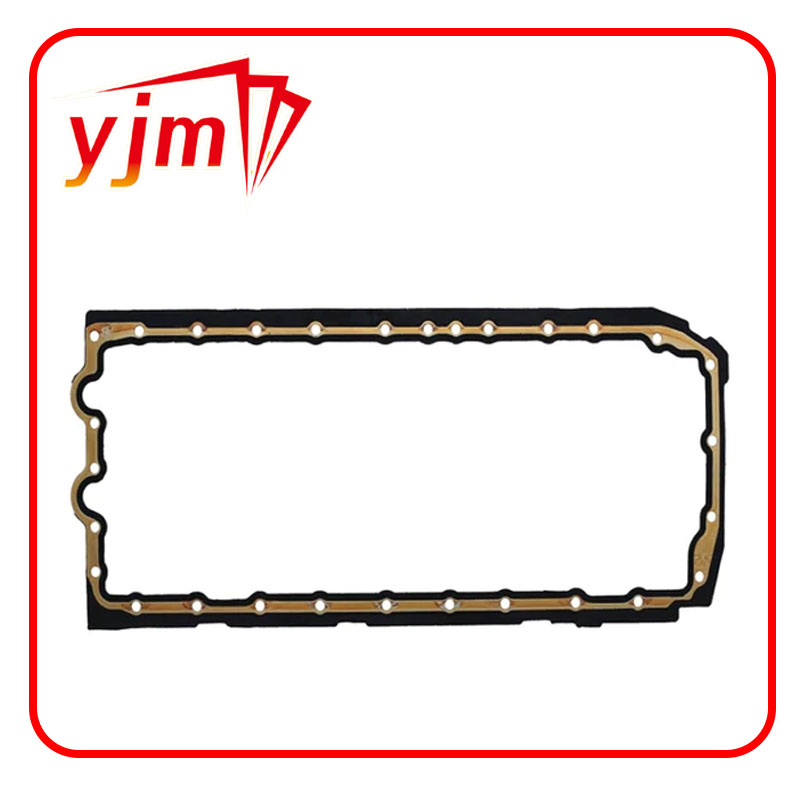

Engine Crankshaft Oil Seal 9031683001

The trustworthiness of automotive shaft seals is validated through real-world performance. Success stories abound, where high-quality seals have transformed the durability and reliability of entire fleets, underscoring their indispensable role in vehicle system integrity. Fleet managers and automotive technicians often attest to the substantial cost savings achieved through reduced leakage, lower maintenance requirements, and prolonged equipment lifespan when employing top-tier shaft seals. Furthermore, as the automotive industry strides towards greater sustainability, shaft seal technology is also evolving. Modern seals are being engineered to be more environmentally friendly, offering reduced friction which not only enhances fuel efficiency but also minimizes wear and tear. This aligns with global efforts to reduce carbon emissions and promote green technologies, ensuring that today's products meet tomorrow's environmental standards. In the realm of electric vehicles (EVs), shaft seals are adapting to meet unique challenges posed by high rotations per minute (RPM) and the absence of traditional lubricants. This calls for innovative solutions that maintain performance without compromising the overall efficiency of the vehicle. To conclude, automotive shaft seals, though often overlooked, are crucial in safeguarding vehicles' operational integrity. Their development and adaptation continue to shape the future of automotive engineering. By leveraging experience, expertise, authority, and trust, stakeholders can ensure that these small components yield substantial benefits, driving automobiles towards a more reliable and sustainable future. To achieve optimal outcomes, embracing high-quality, well-tested shaft seals is not just recommended – it is imperative for anyone intent on maintaining peak vehicle performance.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories