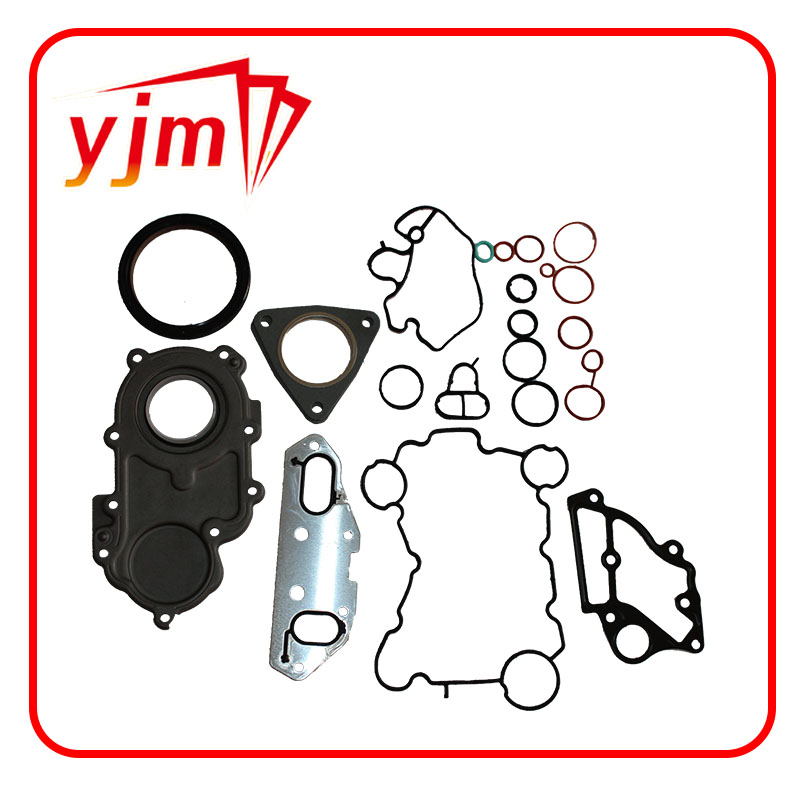

automotive oil seal

From a trustworthiness perspective, oil seal shock absorbers demonstrate consistent performance over long durations, a factor that is critical for vehicle safety and longevity. Industry certifications and rigorous testing protocols further cement their reputation. Testing procedures often involve simulating real-world conditions to assess the limits of these seals, ensuring that they can withstand high-frequency vibrations and resist oil degradation over extended periods. In the realm of product research, particular attention is given to the refinement of these seals to minimize friction and wear. This attention to detail translates to better fuel efficiency and reduces the wear and tear on other vehicle components. Moreover, maintenance of these components is straightforward, requiring checkups primarily during routine vehicle servicing, underscoring their reliability. Ultimately, embracing advancements in oil seal shock absorber technology is not merely a matter of innovation but of necessity. As automotive designs veer towards increased sustainability and efficiency, the demand for components that support these goals without compromising on performance will invariably rise. The oil seal shock absorber exemplifies this synthesis of modern demands and engineering tradition, providing a seamless blend of reliability and precision that the future of automotive technology hinges upon.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories