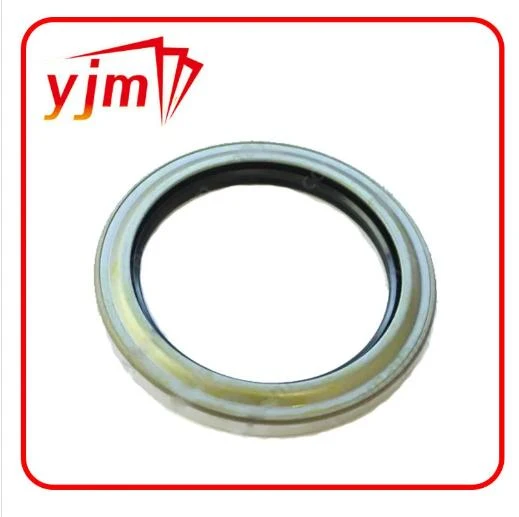

automotive oil seal

Trustworthiness comes from transparency and reliability. Key to establishing trust with users is the sharing of information about the product's material composition, manufacturing process, and performance metrics. Customers should have access to data sheets and certification information that verifies the oil seal’s compliance with international standards like ISO and ASTM. Moreover, brands that offer substantial warranties and customer support are often perceived as more trustworthy because they demonstrate a commitment to customer satisfaction. Case studies and customer testimonials further strengthen trustworthiness. For instance, a manufacturing firm that switched to a higher-quality distributor oil seal experienced a 30% reduction in maintenance costs and a significant decrease in machine downtime. Sharing such real-world applications provides potential customers with tangible evidence of the product's value. In conclusion, the choice of distributor oil seal defines machine reliability and operational success. By focusing on experience, expertise, authoritativeness, and trustworthiness, users can make informed decisions that align with their specific needs. This holistic approach not only benefits individual operations but also fosters long-term partnerships with credible manufacturers, leading to sustained growth and innovation in the industry.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories