ac compressor o rings

Understanding AC Compressor O-Rings Importance and Maintenance

Air conditioning (AC) systems are essential for providing comfort in homes, offices, and vehicles, particularly during the scorching summer months. One crucial component of the AC system is the compressor, responsible for circulating refrigerant and compressing it to maintain optimal system pressure. Within this system, O-rings play a significant role in ensuring efficiency and preventing refrigerant leaks.

What are O-Rings?

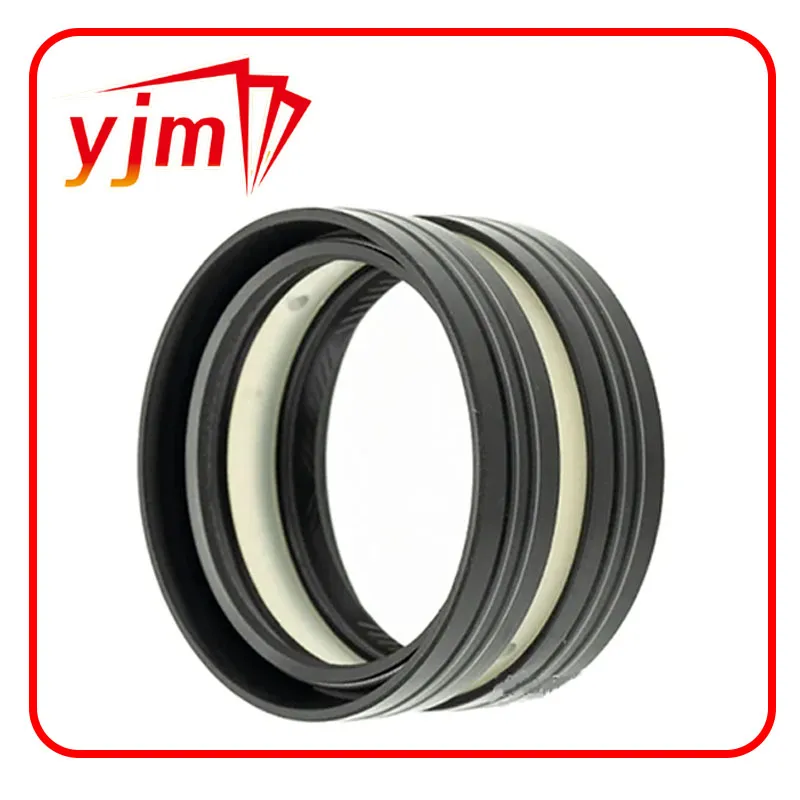

O-rings are circular seals made from various materials such as rubber, silicone, or fluorocarbon. They are designed to fit into grooves on components like the AC compressor, providing a sealing function between two or more parts. In the context of an AC compressor, O-rings prevent the escape of refrigerant and protect the system from external contaminants.

The Role of O-Rings in AC Compressors

In AC compressors, O-rings are used at various junctions, including those between the compressor housing and the manifold as well as the connections to hoses and pipes. Their primary functions are to

1. Seal Refrigerant O-rings trap the refrigerant within the system, allowing the compressor to function efficiently without losing refrigerant due to leaks.

2. Prevent Contamination By sealing gaps, O-rings keep dust, moisture, and other contaminants from entering the compressor, which can lead to corrosion or reduced efficiency.

3. Accommodate Movement O-rings allow for some movement between components of the AC system. As the compressor operates, it may vibrate or shift slightly; O-rings accommodate this motion while maintaining a tight seal.

Common Problems Associated with O-Rings

While O-rings are designed to offer durability, they can wear out over time due to heat, pressure, and exposure to refrigerants

. Here are common issues that might ariseac compressor o rings

1. Degradation Over time, the material of the O-ring can deteriorate due to exposure to high temperatures or aggressive chemicals in refrigerants.

2. Compression Set O-rings can lose their elasticity, becoming flattened and losing their ability to form a proper seal.

3. Improper Installation If the O-ring is not seated correctly during installation, it might not seal properly, leading to leaks.

Maintenance and Replacement

To ensure the longevity and efficiency of your AC system, regular maintenance of O-rings is vital. Here are some key points to consider

1. Regular Inspections During routine HVAC maintenance or vehicle servicing, inspect O-rings for signs of wear such as cracking, swelling, or hardening.

2. Professional Replacement If an O-ring is found to be damaged, it is advisable to have it replaced by a qualified technician to ensure the correct type and size is used.

3. Use Quality Parts Always opt for high-quality O-rings made specifically for AC systems. Generic or low-quality O-rings may not withstand the pressure and temperature conditions present in AC compressors.

4. Lubrication When installing new O-rings, applying a thin layer of compatible lubricant can help facilitate easier insertion and prevent damage during installation.

Conclusion

AC compressor O-rings are small yet indispensable components that play a crucial role in maintaining the efficiency of air conditioning systems. Understanding their function, potential issues, and maintenance is essential for ensuring a reliable AC performance. By taking proactive measures to inspect and replace O-rings when necessary, you can extend the lifespan of your AC system and enjoy a consistently comfortable environment, regardless of the heat outside. Regular preventive maintenance, performed by skilled professionals, not only keeps the system running smoothly but also saves on costly repairs and refrigerant losses in the long run.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories