Similar Oil Seal Specifications 80x100x10 for Enhanced Performance and Durability

Understanding the 80x100x10 Oil Seal A Comprehensive Guide

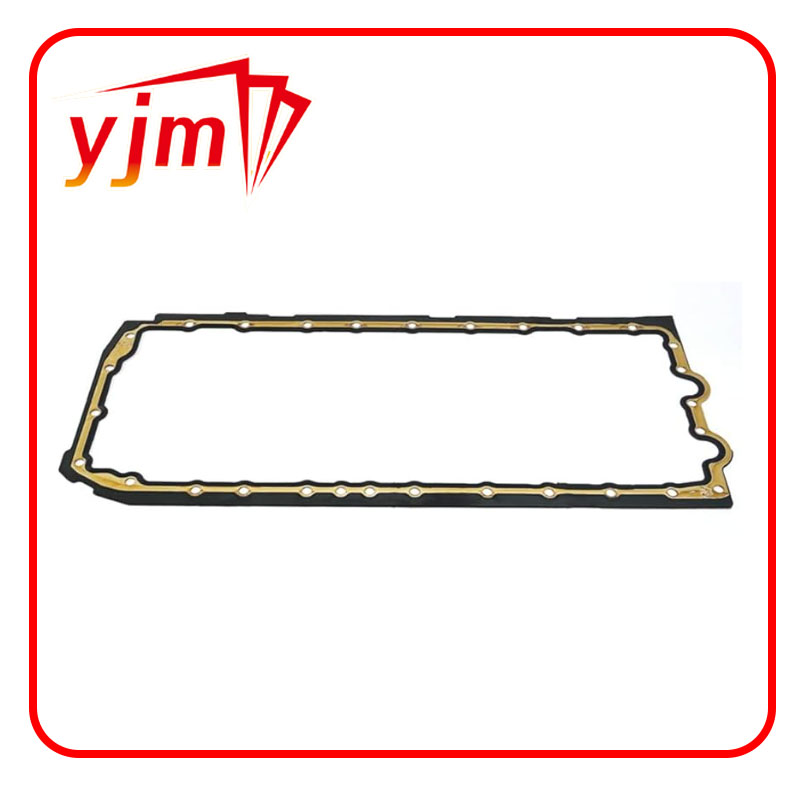

Oil seals, also known as shaft seals or rotary seals, play a crucial role in various mechanical systems, helping to prevent the leakage of lubricants and the ingress of contaminants. Among the many specifications available, the 80x100x10 oil seal features prominently in various applications due to its specific dimensions and design. In this article, we will delve into the importance, applications, and key characteristics of the 80x100x10 oil seal.

What is an Oil Seal?

An oil seal is a device used to contain lubricants in mechanical assemblies and prevent external contaminants such as dust, dirt, and moisture from entering. Typically made from materials like rubber, silicone, or thermoplastic elastomers, oil seals are engineered to perform under a range of environmental conditions, including varying temperatures and pressures.

Specifications of the 80x100x10 Oil Seal

The designation 80x100x10 refers to specific measurements and characteristics of this oil seal

- 80 mm This is the outer diameter of the oil seal. It is designed to fit into a corresponding bore in machinery where sealing is necessary.

- 100 mm This is the inner diameter, which typically corresponds to the diameter of the shaft that the seal will ride on. A proper fit is crucial for efficiency and longevity.

- 10 mm This represents the width of the seal. The width can affect the load-bearing capacity and the overall effectiveness of the seal.

- 20 This figure usually indicates the specific type or design aspect of the seal, which could refer to features such as the lip design, material properties, or specific usage applications.

Importance of Oil Seals

Oil seals serve several essential functions within mechanical systems

1. Leak Prevention They significantly reduce the risk of oil leakage from mechanical assemblies, which not only maintains lubrication but also prevents potential damage to surrounding components.

80x100x10 oil seal

2. Contaminant Protection By forming a tight seal around a shaft, oil seals keep dust, dirt, and moisture at bay, ensuring that the internal environment remains clean and operational.

3. Operating Efficiency A well-fitted oil seal contributes to the overall efficiency of machinery. By minimizing friction and preventing lubricant loss, it helps in maintaining optimal operating conditions.

4. Prolonged Equipment Life By preventing leaks and contamination, oil seals play a vital role in extending the lifespan of machinery. This reduces maintenance costs and downtime, leading to overall cost savings for businesses.

Applications of the 80x100x10 Oil Seal

The 80x100x10 oil seal is versatile, commonly used in various industries, including

1. Automotive In vehicles, oil seals are frequently employed in engines, transmissions, and axles to prevent oil leaks and maintain system integrity.

2. Industrial Machinery Manufacturing equipment, conveyors, and pumps often utilize oil seals to protect against lubricant loss and contamination.

3. Agricultural Equipment Tractors and other farming machinery depend on robust oil sealing solutions to withstand harsh operating conditions.

4. Construction Equipment In heavy machinery, oil seals are essential for the reliable operation of hydraulic systems and gearboxes.

Installation and Maintenance

Proper installation of oil seals is crucial for their performance. Key considerations include ensuring that the sealing surface on the shaft is clean and free from damage. Misalignment during installation can lead to premature seal failure. Regular maintenance checks can help identify any wear or damage to the seals, allowing for timely replacements and ensuring continuous operational efficiency.

Conclusion

The 80x100x10 oil seal is an essential component in protecting mechanical systems from oil leaks and external contaminants. Understanding its specifications, applications, and importance aids in making informed decisions regarding equipment maintenance and selection. By ensuring the proper installation and maintenance of oil seals, businesses can enhance productivity, reduce costs, and extend the life of their machinery. As technology continues to evolve, the design and materials used in oil seals will likely improve, leading to even more effective sealing solutions in the future.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories