Oil Seal Specifications for Enhanced Performance and Durability in Industrial Applications

Understanding the Importance of Oil Seals A Deep Dive into the 55%–80%–10% Concept

Oil seals play a crucial role in various mechanical systems, ensuring that fluids remain contained while preventing contamination from external elements. The concept of the 55%–80%–10% equation appears to symbolize the effectiveness and efficiency of oil seals in industrial applications, suggesting a framework for understanding their importance in machinery.

Understanding the Importance of Oil Seals A Deep Dive into the 55%–80%–10% Concept

Moving on to the 80%, we can view this as reflecting the adaptability and compatibility of oil seals with various machinery and environments. Oil seals are manufactured using diverse materials like rubber, silicone, and metal, each tailored for specific applications. For instance, in the automotive industry, oil seals must withstand high temperatures, corrosive substances, and varying pressure levels. The ability of these seals to adapt plays a pivotal role in their design and effectiveness across a wide range of applications, constituting roughly 80% of what makes them vital components in engineering. Manufacturers must ensure that these seals are fit for purpose, as the correct material and design can significantly enhance their lifespan and functionality.

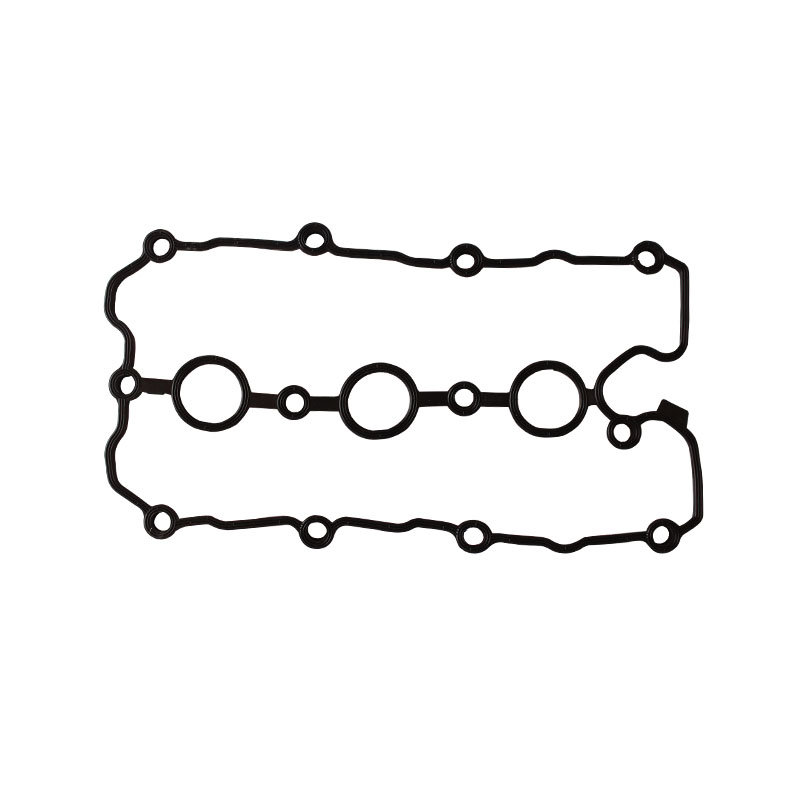

55 80 10 oil seal

Finally, the 10% might highlight the importance of maintenance and proper installation. While oil seals can often operate effectively, their performance hinges significantly on correct fitting and regular maintenance. A mere 10% of attention on these aspects can make a robust difference in the longevity and effectiveness of the seals. Engineers and technicians need to pay attention to details such as surface finish, alignment, and installation techniques. Neglecting these factors can lead to malfunction, diminishing the overall effectiveness of the seals and resulting in costly repairs or replacements.

In conclusion, the 55%–80%–10% framework offers a simplified yet insightful perspective on the roles and impacts of oil seals in machinery. Understanding that the primary function of oil seals is to prevent leakage (55%), adapt to various conditions (80%), and require proper maintenance and installation (10%) allows engineers to prioritize their use effectively. Businesses that invest in high-quality oil seals, along with training staff on installation and maintenance, can expect improved operational efficiency, reduced downtime, and minimized operating costs.

Given these considerations, it’s clear that oil seals are not mere components but vital players in the reliability and performance of machinery. As industries continue to evolve, the ongoing development of higher-quality seals and smarter maintenance practices will be necessary to meet the demands of modern engineering challenges. In an age where efficiency and reliability are paramount, understanding and optimizing every aspect of components like oil seals is essential for longevity and success in industrial applications.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories