Similar Specifications for 50x90x10 Oil Seal Design and Applications

Understanding the 50x90x10 Oil Seal Specifications and Applications

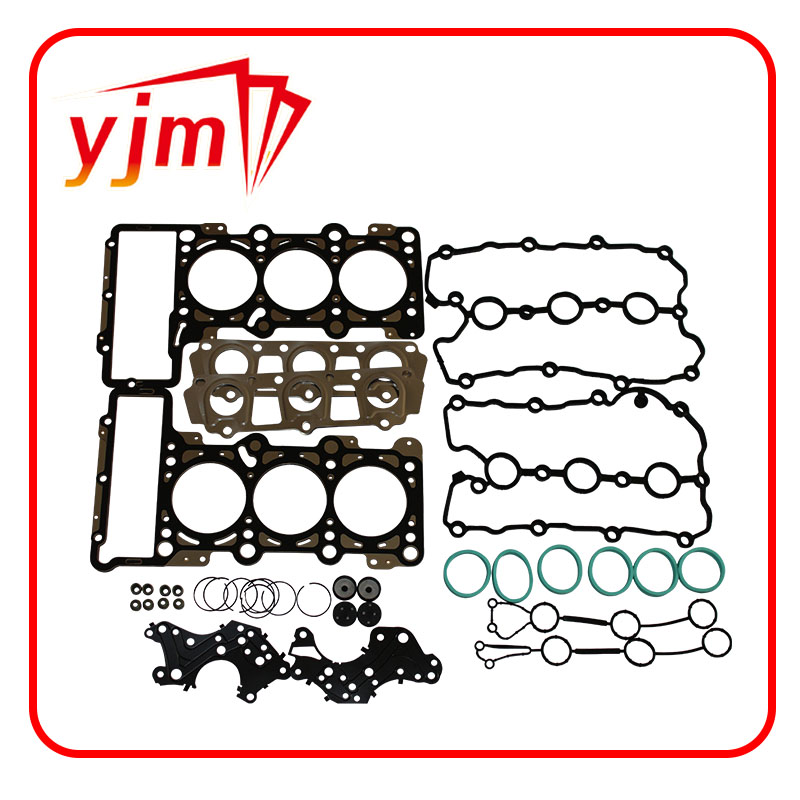

Oil seals, also known as radial shaft seals, play a crucial role in machinery and automotive applications by preventing the leakage of fluids and protecting internal components from contamination. One specific type, the 50x90x10 oil seal, is characterized by its dimensions and specific design features that tailor it to various industrial uses.

Dimensions and Specifications

The nomenclature 50x90x10 refers to the key dimensions of the oil seal. The first number, 50, indicates the inner diameter of the seal in millimeters (mm), which means it is designed to fit onto a shaft or component with a 50mm diameter. The second number, 90, represents the outer diameter of the seal, which is 90mm, allowing it to be securely installed in a cavity or bore with a corresponding size. Finally, the third measurement, 10, signifies the width of the seal, measured in millimeters as well. The additional typically signifies a variation in the seal’s design or material that ensures optimal performance.

Materials and Design Features

Oil seals are typically constructed from various elastomers, such as nitrile rubber (NBR), silicone, or fluorocarbon, with nitrile rubber being the most common due to its excellent resistance to petroleum-based oils and good mechanical properties. The 50x90x10 oil seal’s design includes a sealing lip that dynamically contacts the shaft, creating a barrier against the ingress of dirt and moisture while preventing oil from escaping.

50x90x10 oil seal

This oil seal may also incorporate specific design features, such as a garter spring, which helps maintain consistent contact pressure against the shaft and ensures a tight seal. This is critical in maintaining the integrity of the seal, particularly in dynamic applications where there is relative motion between the sealing lip and the shaft.

Applications

The versatility of the 50x90x10 oil seal makes it suitable for a wide range of applications. It is commonly utilized in automotive systems, such as engines, transmissions, and differentials, where it functions to prevent oil leaks and contamination. Additionally, this oil seal can be found in industrial machinery, hydraulic systems, and agricultural equipment, where ensuring the containment of lubricants is essential to operational efficiency and longevity.

Conclusion

In conclusion, the 50x90x10 oil seal is a vital component in modern machinery and automotive applications, providing effective sealing solutions to prevent fluid leaks and protect sensitive internal components. Understanding its dimensions, material properties, and applications can guide engineers and maintenance professionals in making informed decisions about their use in various systems. Proper installation and selection of the right oil seal are crucial to ensuring the reliability and efficiency of machinery, ultimately leading to lower maintenance costs and extended service life. As technology continues to evolve, oil seals will adapt to meet the demands of increasingly complex machinery, remaining a cornerstone of mechanical engineering.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories