Comparable Title for 45x62x8 Oil Seal Specifications and Applications in Various Industries

Understanding the 45x62x8 Oil Seal A Comprehensive Guide

Oil seals are essential components in various mechanical systems, serving to keep lubricants in and contaminants out of critical machinery. Among the many types of oil seals available, the 45x62x8 oil seal stands out due to its specific dimensions and versatile applications. In this article, we will delve into the features, benefits, and common uses of the 45x62x8 oil seal, shedding light on its importance in maintaining the efficiency and longevity of machines.

Dimensions and Specifications

The designation 45x62x8 refers to the measurements of the oil seal, representing its inner diameter (ID), outer diameter (OD), and thickness. Specifically, the 45mm inner diameter, 62mm outer diameter, and 8mm thickness are precisely engineered for compatibility with various mechanical assemblies. This size is particularly suitable for applications in small to medium-sized machines, where space constraints and performance requirements must be carefully balanced.

The 20 in 45x62x8 oil seal could suggest a particular designation or range; however, this could often represent the compatibility with different oil types or specific industry standards. It's crucial for manufacturers and engineers to refer to specifications provided by the seal manufacturer to choose the right material compound and design for the specific application.

Material and Design

Oil seals are typically made from elastomeric materials like nitrile rubber (NBR), fluoroelastomer (FKM), or silicone, selected based on the working environment and required durability. The choice of material directly influences the seal's resistance to temperature variations, chemical exposure, and friction. For the 45x62x8 oil seal, NBR is commonly used due to its excellent resistance to petroleum-based oils and its ability to perform in a diverse range of temperatures.

Design features such as the sealing lip, spring, and housing configuration contribute to the seal's effectiveness. The sealing lip needs to be designed to provide adequate contact with the shaft while managing any axial or radial movements during operation. Additionally, some oil seals have a built-in spring that helps maintain the correct tension against the shaft, enhancing the seal's performance over time.

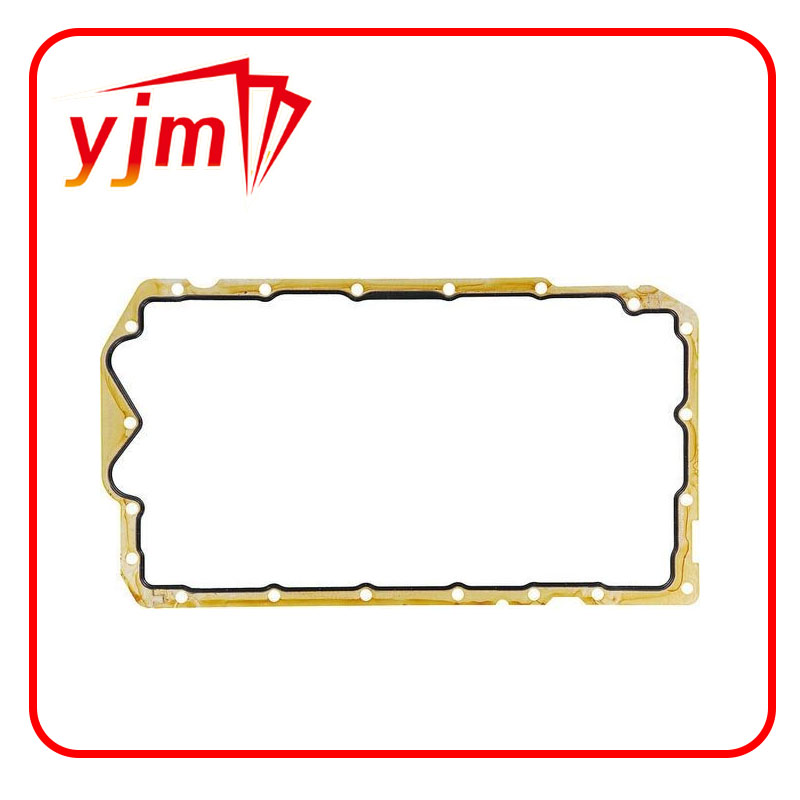

45x62x8 oil seal

Applications

The versatility of the 45x62x8 oil seal makes it suitable for diverse applications across various industries

. It is commonly found in automotive, agricultural, and industrial machinery, particularly in motor vehicles, gearboxes, pumps, and hydraulic systems. The ability of the oil seal to prevent the leakage of oils and lubricants while blocking out dirt, dust, and water is critical in maintaining the performance efficiency of these systems.In automotive applications, for instance, the 45x62x8 oil seal may be used to seal transmission components, ensuring that the lubrication remains intact to reduce friction and wear. Without a properly functioning oil seal, vehicles may experience oil leaks, leading to increased operational costs and potential mechanical failures.

Benefits of Using the 45x62x8 Oil Seal

1. Enhanced Longevity By effectively sealing in lubrication and preventing contamination, oil seals contribute to prolonged machinery life. 2. Improved Performance Maintaining the correct lubricant levels helps ensure that machinery operates at peak efficiency. 3. Cost-Effective Maintenance Investing in quality oil seals like the 45x62x8 can reduce the frequency of maintenance and repairs due to leaks or component failure.

4. Versatility The 45x62x8 oil seal can be utilized in various applications, making it a valuable component in numerous industries.

Conclusion

In summary, the 45x62x8 oil seal is a vital component in today’s mechanical systems, offering reliable sealing solutions for a wide range of applications. Its design, material selection, and specific dimensions make it particularly effective in preserving the integrity of lubricated systems. Understanding the significance of this oil seal can assist manufacturers and engineers in selecting the right components, ultimately leading to better machine performance and reduced maintenance costs.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories