4.3 oil pan bolt size

Understanding the 4.3% Oil Pan Bolt Size Importance and Considerations

When it comes to maintaining and repairing vehicles, particularly those equipped with a 4.3L engine, the oil pan is a critical component. Its proper functioning ensures that the engine is lubricated efficiently, enabling it to run smoothly and preventing severe damage. Therefore, understanding the specifics surrounding the oil pan, including the bolt size, is essential for any vehicle owner or mechanic.

The Role of the Oil Pan

The oil pan, also known as a sump, is located at the bottom of the engine and serves as a reservoir for the engine oil. It plays a crucial role in collecting and storing the oil that lubricates various engine components. The design and integrity of the oil pan are vital, not only for containment but also for ensuring that the oil can circulate effectively throughout the engine.

Importance of Proper Bolt Sizing

One of the often-overlooked aspects of the oil pan is the bolts that secure it to the engine block. For the 4.3L engines, the size and type of these bolts are particularly important. Using the incorrect bolt size can lead to several issues

1. Oil Leaks If the bolts are too small, they may not provide a tight seal, causing oil to escape. Conversely, using bolts that are too large can damage the threads and lead to similar problems.

2. Structural Integrity The oil pan needs to be tightly secured to withstand the vibrations and stresses that occur during engine operation. Proper bolt size ensures that the pan remains intact, preventing any potential detachment that could result in engine failure.

3. Ease of Maintenance Having the correct bolt size simplifies the process of removing and replacing the oil pan, which is necessary during oil changes or repairs. If the bolts are not the appropriate size, they may be challenging to work with, increasing the time and effort required for maintenance.

Standard Specifications for 4.3L Oil Pan Bolts

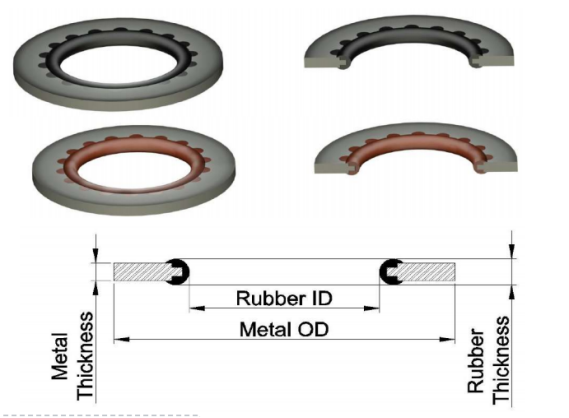

4.3 oil pan bolt size

For those working on 4.3L engines, it is essential to understand the standard specifications for the oil pan bolts. Generally, these bolts are classified as metric or standard, with specific measurements that dictate their use. The common bolt size for the 4.3L oil pan is typically around 10mm in diameter with varying lengths depending on the application and mounting points.

When sourcing replacement bolts, it is advisable to use parts that meet OEM (Original Equipment Manufacturer) specifications to ensure compatibility and performance. This helps prevent any issues related to improper fitment and ensures that the connections are strong and reliable.

Best Practices for Installation

When installing or replacing the oil pan and its bolts, following proper procedures can make a significant difference in the performance and longevity of the engine

1. Clean the Surfaces Before reattaching the oil pan, ensure that both the pan and the engine block surfaces are clean and free of any old gasket material or debris. This helps achieve a tight seal.

2. Use a Torque Wrench It is essential to follow the manufacturer’s guidelines regarding torque specifications when tightening the bolts. Using a torque wrench helps ensure that the bolts are neither too loose nor too tight, preventing damage to the oil pan or engine block.

3. Check for Leaks After installation, run the engine and check for any signs of oil leaks. Addressing any leaks immediately will help maintain engine health.

Conclusion

Understanding the 4.3% oil pan bolt size is essential for anyone involved in the maintenance or repair of vehicles featuring the 4.3L engine. The right bolt size not only ensures the integrity and functionality of the oil pan but also contributes to the overall health of the engine. By adhering to standard specifications and following best practices during installation, vehicle owners and mechanics can help prevent potential problems and prolong engine life.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories