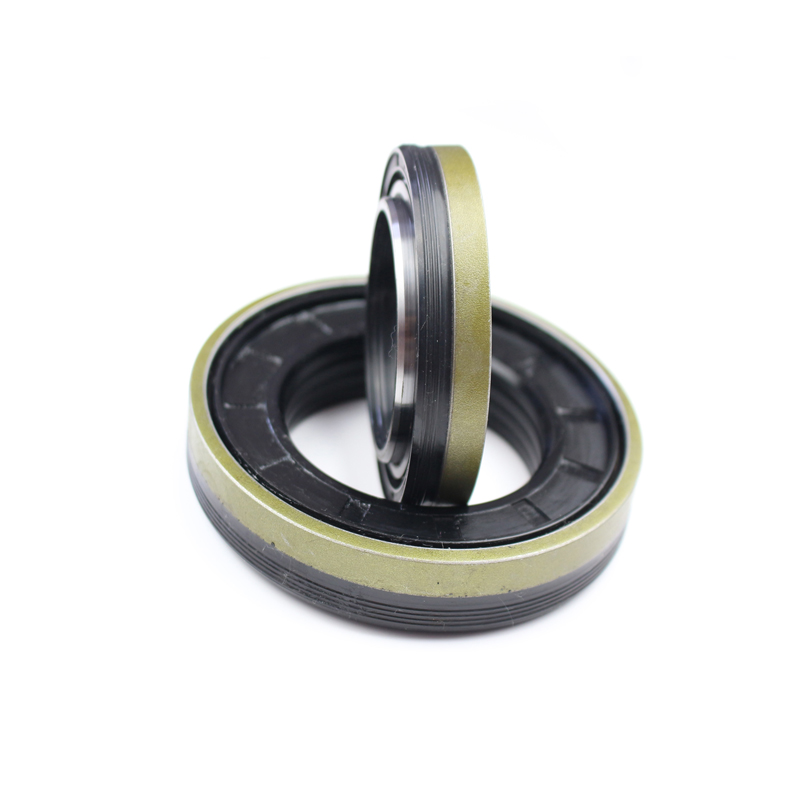

40x55x8 oil seal

Understanding the 40x55x8 Oil Seal A Vital Component in Mechanical Systems

In the realm of mechanical engineering and maintenance, oil seals play a critical role in ensuring the efficient performance of machinery. One of the commonly utilized sizes is the 40x55x8 oil seal. These dimensions refer to the seal’s inner diameter (40 mm), outer diameter (55 mm), and thickness (8 mm). Understanding the purpose and function of this specific oil seal is essential for anyone involved in machinery maintenance or repair.

Oil seals are designed to prevent the leakage of lubricants and fluids, while simultaneously keeping out contaminants such as dust, dirt, and moisture. This is especially important in rotating machinery, where the smooth operation depends on the integrity of the lubrication system. The 40x55x8 oil seal is typically used in various applications, including automotive engines, hydraulic systems, and industrial machinery.

One of the key benefits of using oil seals like the 40x55x8 is their ability to maintain a clean internal environment. By preventing dirt and other particles from entering the machinery, oil seals protect critical components such as bearings and gears from wear and tear. This not only prolongs the life of the machinery but also enhances its overall performance and efficiency.

40x55x8 oil seal

The materials used in the construction of oil seals are also crucial. Most oil seals are made from rubber or polymer materials, which provide flexibility and a tight seal against surfaces. The 40x55x8 oil seal may incorporate special additives to enhance its temperature and wear resistance, making it suitable for demanding environments.

Moreover, proper installation of the 40x55x8 oil seal is vital for realizing its benefits. This involves ensuring that the sealing surface is clean and free from damage, as any imperfection could lead to leakage. Regular inspections should also be conducted to check for signs of wear or deterioration, as early detection can prevent extensive damage to machinery.

In conclusion, the 40x55x8 oil seal is a small yet crucial component that plays a significant role in the operation of various mechanical systems. Its ability to seal against leaks and contaminants ensures that machinery runs smoothly and efficiently, helping to reduce maintenance costs and downtime. Understanding and maintaining this part can lead to enhanced performance, longer equipment life, and ultimately, greater operational success in any mechanical application.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories