40x52x7 oil seal

Understanding the 40x52x7 Oil Seal Specifications and Applications

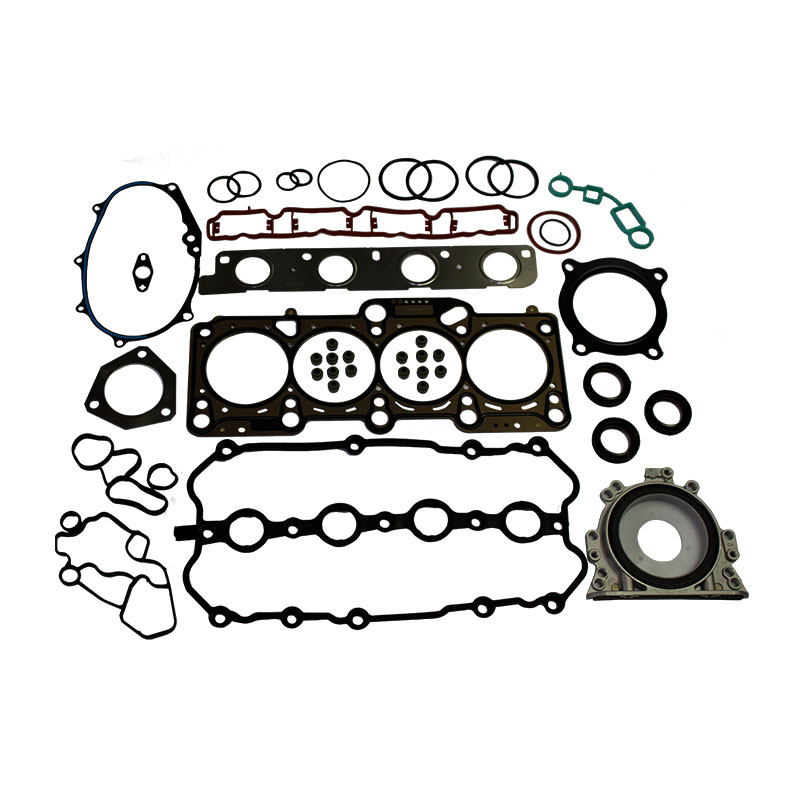

Oil seals are crucial components utilized in various machinery and automotive applications. They serve to prevent the leakage of lubricants and protect mechanical parts from dirt and debris. One of the common oil seal dimensions is 40x52x7, which refers to its outer diameter, inner diameter, and the thickness of the seal. In this article, we’ll delve into the specifications, materials, functions, and applications of the 40x52x7 oil seal.

Specifications of 40x52x7 Oil Seal

The dimensions of the 40x52x7 oil seal indicate that the outer diameter measures 52mm, the inner diameter is 40mm, and the thickness of the seal is 7mm. This specific sizing makes it suitable for various applications where a compact yet effective sealing solution is necessary.

Oil seals often come equipped with features such as

1. Material Composition Generally made from rubber, oil seals may also incorporate additional materials such as fabric or metal to reinforce durability and performance. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone rubber, each chosen based on the specific requirements of the application, such as temperature resistance and chemical compatibility.

2. Design The 40x52x7 oil seal may feature different designs, including single-lip or double-lip seals. Single-lip seals are designed primarily to retain oil, while double-lip seals offer enhanced protection against contamination.

3. Temperature and Pressure Ratings The operating temperature and pressure specifications are vital for ensuring the seal's longevity and effectiveness. Comprehensive knowledge of the working environment helps in selecting the appropriate oil seal variant.

Function of the 40x52x7 Oil Seal

The primary function of the 40x52x7 oil seal is to seal the areas where shafts pass through housing or casings, preventing lubricant leakage and restricting foreign particles from entering. This sealing action is essential in various applications, ensuring that the machinery operates smoothly and efficiently.

40x52x7 oil seal

1. Lubrication Maintenance By preventing oil leaks, the seal maintains proper lubrication levels, reducing friction and wear on moving parts, thus prolonging the lifespan of the equipment.

2. Contamination Prevention The oil seal acts as a barrier against contaminants such as dust, dirt, moisture, and debris, ensuring that the internal components remain clean and functioning effectively.

3. Pressure Retention In many applications, oil seals are designed to withstand various pressures, retaining oil even in high-stress environments.

Applications of the 40x52x7 Oil Seal

The versatility of the 40x52x7 oil seal allows it to be used in numerous applications, notably within the automotive sector, industrial machinery, and household appliances.

1. Automotive Industry In vehicles, this size oil seal commonly protects engine components, transmission systems, and differential housing. Its ability to withstand high temperatures and pressures makes it ideal for automotive applications where performance is critical.

2. Industrial Machinery The seal is frequently found in pumps, compressors, and motors where it helps to maintain optimal operation by preventing leaks in hydraulic and pneumatic systems.

3. Home Appliances Various household items such as washing machines and refrigerators also utilize oil seals. The 40x52x7 oil seal aids in the proper functioning of motors and other mechanical parts.

Conclusion

In summary, the 40x52x7 oil seal is a vital component in numerous mechanical systems, offering an effective solution for preventing oil leaks and protecting against contamination. By understanding its specifications, functions, and key applications, engineers and technicians can select the appropriate oil seal to meet their specific needs. Whether in automotive, industrial, or household applications, the 40x52x7 oil seal plays an essential role in ensuring machinery operates efficiently and reliably. When considering replacements or upgrades, understanding these elements can lead to better maintenance practices and improved machinery lifespan.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories