Exploring the Benefits of 40%-80%-10% Oil Seal Composition for Enhanced Performance

Understanding the 40%-80%-10% Oil Seal Concept

In the realm of mechanical engineering and sealing technology, the oil seal plays a pivotal role in ensuring the efficiency and longevity of machinery. A critical consideration in the design and functionality of oil seals can be encapsulated in the concept of the 40%-80%-10% ratio. This principle serves as a guideline to optimize the performance of oil seals in various applications.

The 40% Contribution Material Selection and Design

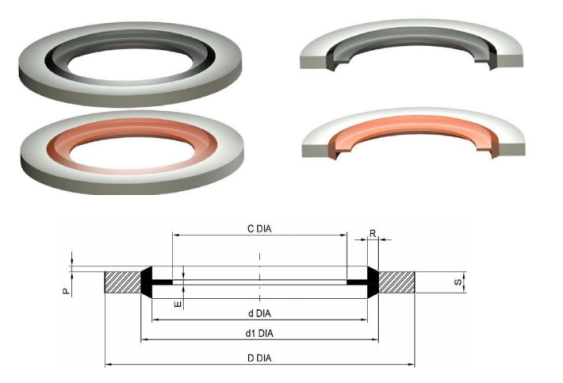

The first aspect, representing 40%, pertains to the choice of materials and the design of the oil seal itself. The materials used in oil seals must exhibit excellent wear resistance, chemical compatibility, and the ability to maintain their integrity under varied temperature ranges. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and silicone, each offering unique properties suitable for specific applications.

Furthermore, the design of the oil seal, including its shape, hardness, and the type of lip configuration, significantly impacts its sealing capability. A well-designed seal can effectively prevent the leakage of lubricants while keeping contaminants at bay, ensuring optimal machinery performance.

The 80% Contribution Performance and Reliability

40 80 10 oil seal

The second element, accounting for 80%, refers to the performance and reliability of the oil seal in operational conditions. An oil seal must manage not only the static and dynamic pressures but also accommodate thermal expansion, vibrations, and misalignments within machinery.

Effective lubrication within the operating environment enhances the lifespan of oil seals. Thus, understanding the specific climate and chemical interactions that the seal will encounter is vital. For instance, in high-temperature applications, seals designed with materials that can withstand thermal degradation are necessary. Reliability is paramount; a single failure can lead to significant machinery downtime and costly repairs.

The 10% Contribution Maintenance and Monitoring

Finally, the remaining 10% highlights the importance of maintenance and monitoring in extending the life of oil seals. Regular inspections can identify early signs of wear or degradation, enabling preemptive measures to be taken to replace seals before catastrophic failure occurs. Machine operators should be trained in recognizing the signs of oil seal failure, such as leaks or unusual noises, which can indicate the need for intervention.

In conclusion, the 40%-80%-10% concept regarding oil seals encapsulates a comprehensive approach to ensuring effective sealing in machinery. By focusing on material selection and design, emphasizing performance and reliability, and prioritizing maintenance and monitoring, engineers and technicians can significantly enhance the operational efficiency of their equipment. Understanding this ratio not only aids in the selection of appropriate oil seals for various applications but also plays a critical role in prolonging the lifespan of machinery while minimizing operational disruptions. Thus, embracing this concept is beneficial for both manufacturers and end-users alike.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories