38x52x7 Oil Seal - High Quality & Durable Seals for Optimal Performance

Understanding the 38x52x7 Oil Seal An Essential Component in Machinery

Oil seals, also known as fluid seals, are crucial components in machinery that help to contain lubricants, preventing leaks and ensuring the effective operation of various mechanical systems. One specific type of oil seal that is widely used in various industrial applications is the 38x52x7 oil seal. This article will explore the characteristics, applications, and importance of this oil seal size in maintaining machinery efficiency.

Characteristics of the 38x52x7 Oil Seal

The designation 38x52x7 indicates the dimensions of the oil seal in millimeters. The first number, 38, refers to the inner diameter, while the second number, 52, represents the outer diameter. The last number, 7, indicates the thickness of the seal. These dimensions are crucial, as they need to fit snugly into the designated housing to create an effective barrier against the escape of lubricants.

Made from materials such as rubber, silicone, or polyurethane, the 38x52x7 oil seal is designed to withstand harsh operating conditions, including extreme temperatures and exposure to various chemicals. The material choice affects the seal's durability, flexibility, and resistance to wear, making a proper selection essential for the longevity of machinery.

Applications of the 38x52x7 Oil Seal

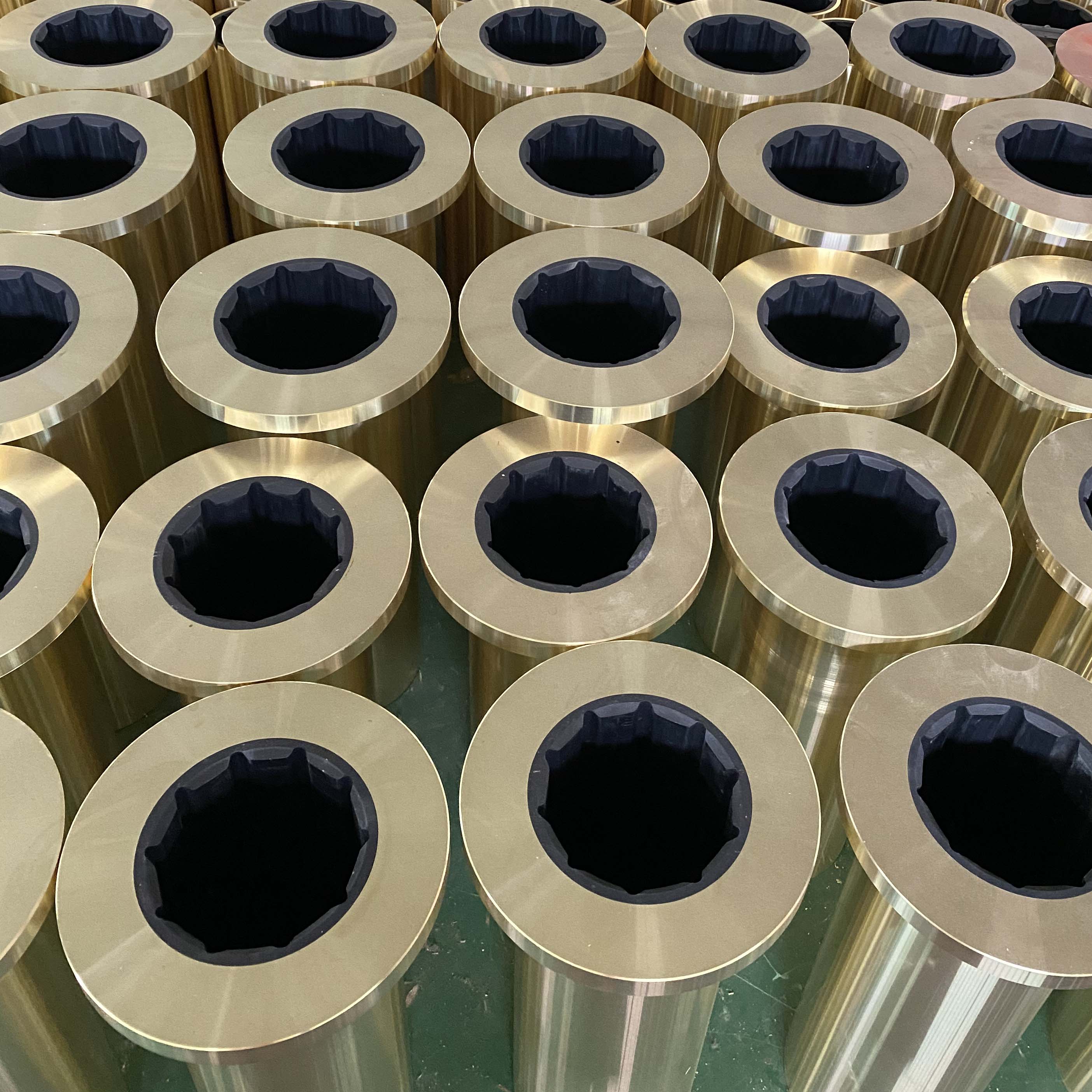

38x52x7 oil seal

The 38x52x7 oil seal finds its application in a multitude of industries. It is commonly used in automotive and truck engines, gearboxes, pumps, and agricultural machinery. These seals are typically employed to prevent oil leaks from rotary shafts, which are crucial for reducing friction and wear in moving parts.

In automotive mechanisms, for instance, the 38x52x7 oil seal can be found in crankshafts and drive axles, where they play a critical role in maintaining oil pressure and preventing contamination that could lead to engine wear. In pumps, this oil seal ensures that the lubricants remain contained, enhancing the efficiency of fluid transfer and minimizing the risk of failure due to leaks.

Importance of Maintaining Oil Seals

Regular maintenance and inspection of oil seals, including the 38x52x7 variety, are essential to ensure optimal performance and longevity of machinery. A worn or damaged seal can lead to oil leaks, which not only result in increased maintenance costs but can also compromise the performance of the machinery. Additionally, leaks can pose environmental hazards, making it imperative for operators to monitor the condition of these seals diligently.

In conclusion, the 38x52x7 oil seal is a vital component in many mechanical systems, providing the necessary barrier to prevent oil leaks and maintain the efficiency of machinery. Understanding its characteristics, applications, and importance is crucial for anyone involved in the maintenance and operation of industrial equipment. By ensuring the integrity of oil seals, companies can enhance the performance and reliability of their machinery, ultimately leading to greater productivity and reduced operational costs.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories