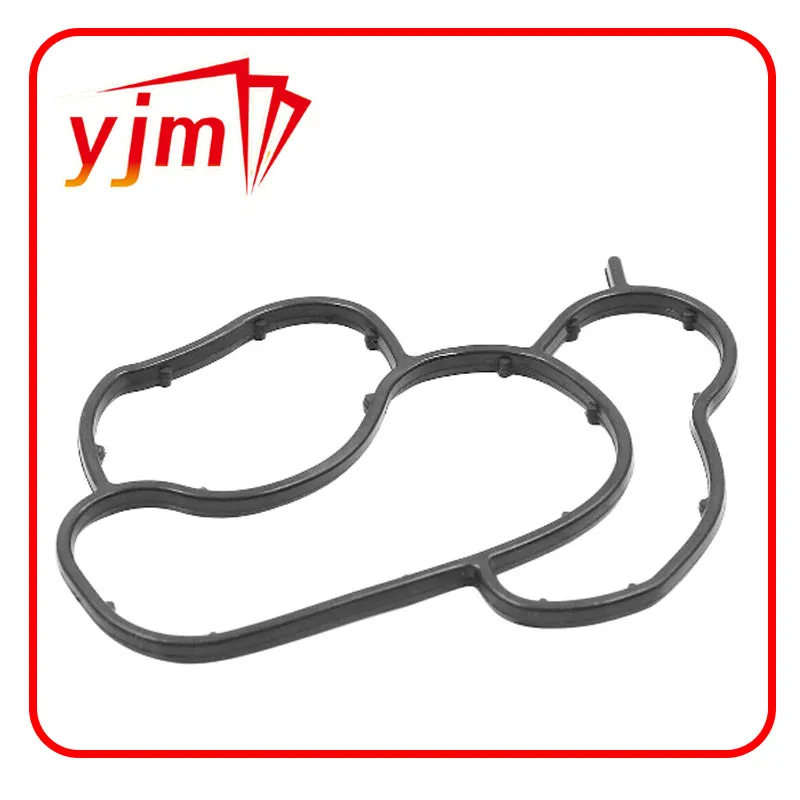

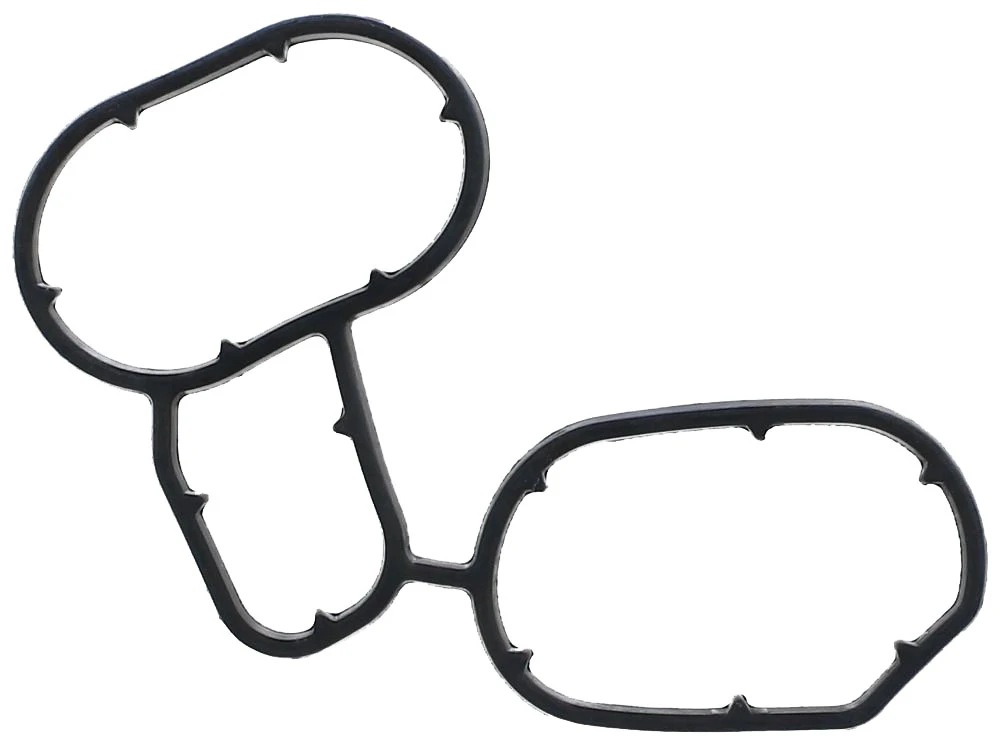

Oil Drain Screw Gasket Oil Crush Washer 12157-10010

From another perspective, the customization industry for printing and crafts can make use of these dimensions as guidelines for bespoke projects. Personalized items require precision to ensure that designs are sharp, vibrant, and exactly as intended. Artists and craftspeople use these measurements to create tailored pieces for their clients, whether that's bespoke furniture elements, unique art frames, or custom signage. For this market, the value lies not only in the functionality but also in the aesthetic allure and personal touch. In understanding why specific measurements such as 35x55x8 matter, it's crucial to emphasize expertise, trust, and authority in providing these products. Clients rely on manufacturers and suppliers with proven track records and positive reviews, signifiers of past performance and reliability. Companies that demonstrate an understanding of what these dimensions mean for diverse applications position themselves as leaders in their respective markets. This knowledge instills trust in potential buyers, assuring them of optimal product performance tailored to their unique requirements. For readers, whether they're project managers, engineers, or even laypeople seeking to understand product specifications for a purchase or project, awareness and knowledge are key. A company that not only recognizes the importance of these dimensions but actively educates its clients on why they matter establishes itself as an industry authority. This commitment to informed customer relations can lead to strong brand loyalty and repeat business. Thus, the specificity encapsulated in 35x55x8 is not merely a dimension; it represents a dedication to meeting precise industrial and consumer needs, enhancing the functionality and satisfaction of the final product. Companies and individuals both benefit from embracing the value of these measurements, recognizing that precision is not just a number—it is the backbone of performance, trust, and exemplary standards in every related product and service.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories