Replacement Options for 35x52x7 Oil Seal for Enhanced Performance and Durability

Understanding the 35x52x7 Oil Seal Its Importance and Applications

Oil seals are essential components in many mechanical systems, serving vital functions that ensure the longevity and efficiency of machinery. Among the various types of oil seals, the 35x52x7 oil seal stands out due to its specific dimensions and versatile applications. In this article, we will explore what a 35x52x7 oil seal is, its construction, importance, and the industries that rely on it.

What is a 35x52x7 Oil Seal?

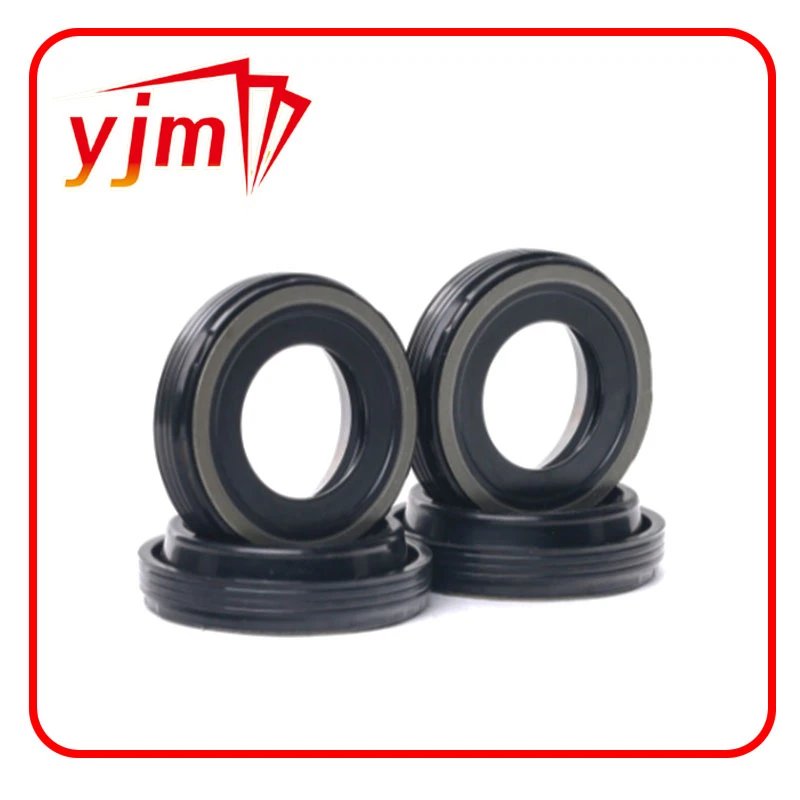

The naming convention of the 35x52x7 oil seal refers to its dimensions in millimeters. Specifically, it has an inner diameter of 35 mm, an outer diameter of 52 mm, and a thickness of 7 mm. These measurements indicate the seal's fit for particular shafts and housings. The primary function of an oil seal is to prevent the leakage of lubricants while also keeping contaminants like dirt and moisture from entering the system.

Oil seals are typically made from elastomeric materials such as rubber or polyurethane, which provide excellent flexibility and resistance to wear and tear. The 35x52x7 oil seal often features a lip that creates a tight seal against the rotating shaft, minimizing friction and extending the life of the component.

Importance of the 35x52x7 Oil Seal

The use of oil seals, notably the 35x52x7 variant, is crucial in maintaining the integrity of various mechanical systems. Here are some reasons why this specific oil seal is important

1. Leak Prevention The primary function of an oil seal is to prevent oil or lubricant from leaking out of the application it is employed in. Leakages can lead to low lubrication levels, which in turn can cause increased wear and potential system failure.

2. Contaminant Protection The oil seal also plays a critical role in keeping contaminants like dirt, dust, and water out of the lubricated areas. This protection is vital for maintaining the cleanliness of lubricated surfaces, ensuring efficient operation.

3. Reduced Friction Proper sealing minimizes friction between moving parts, which is essential for smooth operation. High friction can lead to heat generation and excessive wear on the machine components.

35x52x7 oil seal

4. Cost-Effectiveness By preventing leaks and contamination, oil seals extend the lifespan of machinery and reduce maintenance costs. This ensures that the machinery can operate efficiently for longer periods, leading to savings for companies.

Applications of the 35x52x7 Oil Seal

The 35x52x7 oil seal finds application across various industries. Some of the most common uses include

- Automotive Industry It is often used in engines, transmissions, and differentials, where it helps seal the areas around rotating shafts to prevent oil leaks.

- Industrial Machinery Manufacturing equipment, pumps, and compressors utilize these oil seals to protect against lubricant leakage and contamination.

- Agricultural Equipment Tractors and other farm machinery incorporate oil seals to ensure their hydraulic and lubrication systems function smoothly.

- Aerospace In aviation, oil seals are crucial for maintaining the performance of various systems, ensuring safety and reliability in aircraft operations.

Conclusion

The 35x52x7 oil seal is a small but mighty component that plays a significant role in the functionality of various machines and vehicles. Its ability to prevent leaks, protect against contaminants, reduce friction, and ultimately drive cost savings makes it invaluable across numerous sectors. Understanding the importance of such components can help engineers, mechanics, and manufacturers make informed decisions about machinery maintenance and component selection. By ensuring that the right oil seals are utilized, industries can achieve higher efficiency, reduced downtime, and enhanced safety in their operations.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories