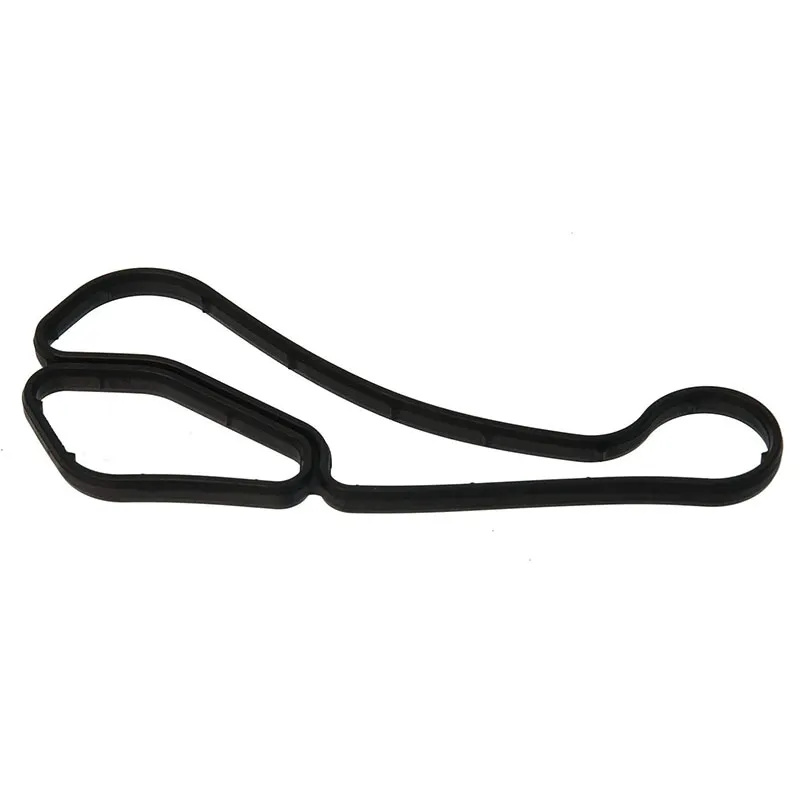

Engine Crankshaft Oil Seal 9031683001

Real-world experience underscores the importance of installing the 30x42x7 oil seal correctly to prevent premature failure. Proper fitting involves ensuring the shaft is clean and free of nicks, and the seal’s housing offers a tight fit to prevent leakage. Installation tools are often recommended to avoid damaging the seal's lip, which forms the critical barrier against lubricant leakage. Regular inspection and maintenance regimes further enhance the trustworthiness of machinery fitted with 30x42x7 oil seals. Operators should routinely check for signs of wear, such as leaks or vibrations, indicative of a seal nearing the end of its operational life. Such proactive maintenance prevents catastrophic failures, ensuring machinery continues to perform at optimal levels. The domain expertise required in dealing with oil seals, particularly the 30x42x7 size, cannot be overstated. With the proliferation of machinery across industries, selecting the right seal ensures operational efficiency and cost-effectiveness. It is a decision that reverberates through the equipment’s lifecycle, affecting productivity, safety, and sustainability. In conclusion, the 30x42x7 oil seal stands out as a paragon of engineering that combines material science, precision manufacturing, and practical application knowledge. For industries relying on the seamless operation of machinery, this small yet mighty component is indispensable, providing robustness, reliability, and peace of mind—all crucial factors for any organization striving for excellence in performance and productivity.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories