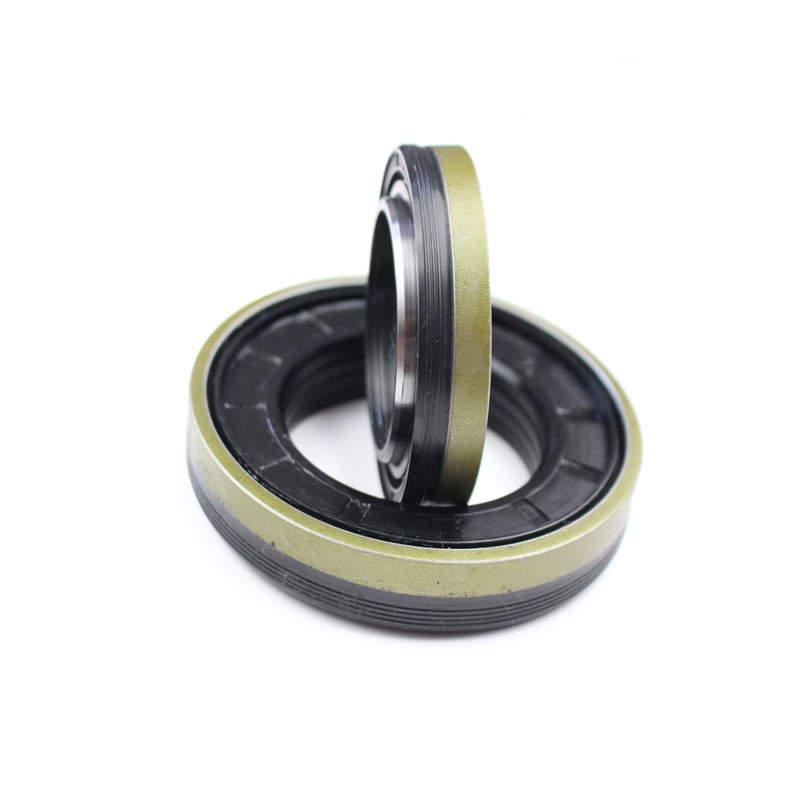

3% oil seal for 8% shaft.

To address this issue, continuous research and development are directed towards enhancing the durability and effectiveness of shaft seals

To address this issue, continuous research and development are directed towards enhancing the durability and effectiveness of shaft seals

To address this issue, continuous research and development are directed towards enhancing the durability and effectiveness of shaft seals

To address this issue, continuous research and development are directed towards enhancing the durability and effectiveness of shaft seals 3 8 shaft seal. Advancements in materials science have led to the creation of more resilient and chemically resistant elastomers, thermoplastics, and composite materials. Additionally, design improvements focus on better fitting tolerances, improved lubrication channels, and the use of secondary seals or backup seals to provide redundancy in critical applications.

Moreover, the correct installation of shaft seals cannot be overstated. It requires precise measurements, clean surfaces, and careful handling to prevent damage that could lead to early failure. Education and training for maintenance personnel are crucial in ensuring that these components are handled and installed correctly.

In conclusion, while the 3% to 8% failure rate of shaft seals may seem like a minor statistic, its impact on industrial operations can be considerable. By focusing on material innovation, design optimization, and proper installation procedures, we can work towards minimizing these numbers and maximizing the overall efficiency and reliability of machinery. As technology continues to progress, the future of shaft seals looks promising, with an increasing emphasis on longevity and performance that will undoubtedly benefit a wide range of industries.

3 8 shaft seal. Advancements in materials science have led to the creation of more resilient and chemically resistant elastomers, thermoplastics, and composite materials. Additionally, design improvements focus on better fitting tolerances, improved lubrication channels, and the use of secondary seals or backup seals to provide redundancy in critical applications.

Moreover, the correct installation of shaft seals cannot be overstated. It requires precise measurements, clean surfaces, and careful handling to prevent damage that could lead to early failure. Education and training for maintenance personnel are crucial in ensuring that these components are handled and installed correctly.

In conclusion, while the 3% to 8% failure rate of shaft seals may seem like a minor statistic, its impact on industrial operations can be considerable. By focusing on material innovation, design optimization, and proper installation procedures, we can work towards minimizing these numbers and maximizing the overall efficiency and reliability of machinery. As technology continues to progress, the future of shaft seals looks promising, with an increasing emphasis on longevity and performance that will undoubtedly benefit a wide range of industries. -

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories