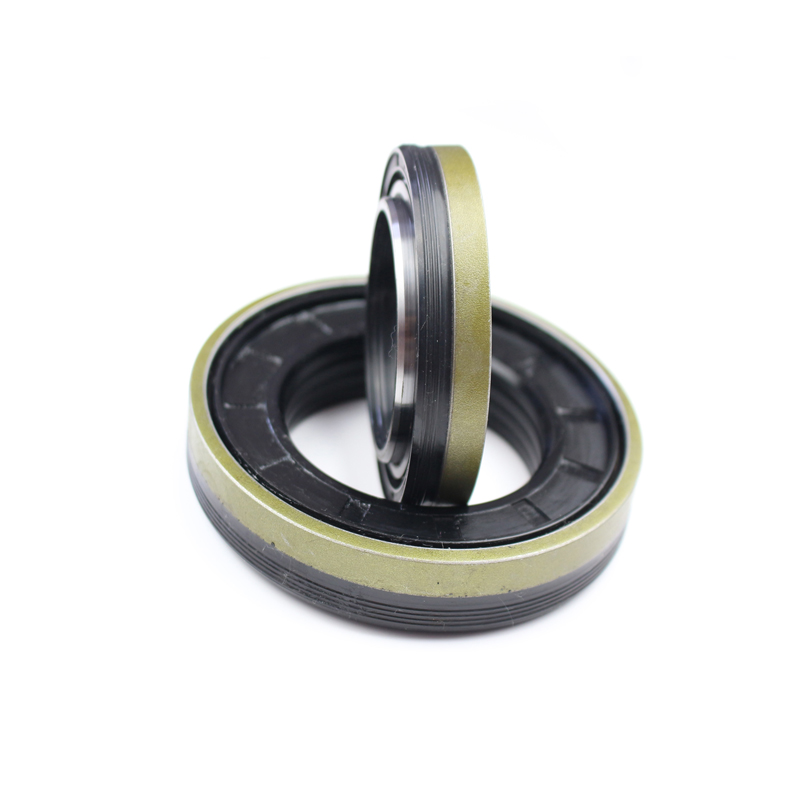

25x35x7 Oil Seal Specifications and Applications for Mechanical Engineering Use

Understanding the 25x35x7 Oil Seal Importance, Application, and Benefits

Oil seals, also known as lip seals or radial seals, are crucial components in various mechanical systems. Their primary purpose is to retain lubricants within a system while preventing contaminants such as dust and debris from entering. Among the myriad of oil seals available in the market, the 25x35x7 oil seal stands out due to its specific dimensions and applications.

What is a 25x35x7 Oil Seal?

The designation 25x35x7 refers to the dimensions of the oil seal in millimeters. Specifically, the first number (25) represents the inner diameter of the seal, the second number (35) corresponds to the outer diameter, and the last number (7) indicates the thickness of the seal. This particular size is commonly used in various automotive and industrial applications, where reliable sealing is paramount.

Importance of Oil Seals

Oil seals play a vital role in the longevity and efficiency of mechanical systems. They are instrumental in

1. Preventing Leakage Oil seals ensure that lubricants remain within engine components, gearboxes, and other machinery. A properly functioning seal prevents leakage, which can lead to severe mechanical failures.

2. Protecting Against Contaminants By keeping dirt, moisture, and foreign particles out, oil seals help maintain the integrity of lubricant properties and ensure smooth operation.

3. Enhancing Equipment Lifespan With effective sealing, the wear and tear on machinery significantly decrease, extending the lifespan and reliability of equipment.

4. Improving Performance By maintaining the correct amount of lubricant in a system, oil seals contribute to optimal operation, enhancing overall performance.

Applications of the 25x35x7 Oil Seal

The 25x35x7 oil seal is versatile and finds applications across several industries

25x35x7 oil seal

1. Automotive Industry In vehicles, this oil seal is often used in engines, transmissions, and differential assemblies. Its ability to retain motor oil while preventing contamination makes it indispensable for automotive performance.

2. Industrial Machinery Many industrial machines rely on this oil seal to protect rotating shafts. Applications include pumps, motors, and gearboxes, where the integrity of the lubrication system is critical for optimal operation.

3. Agricultural Equipment Tractors and other farming machinery often employ this type of seal to ensure that heavy-duty components can operate efficiently under harsh conditions.

4. Marine Applications Boats and ships require robust sealing solutions to combat water intrusion. The 25x35x7 oil seal helps keep lubricants intact and equipment functioning smoothly in challenging maritime environments.

Selecting the Right Oil Seal

Choosing the correct oil seal is essential for ensuring optimal performance in any mechanical system. When selecting a 25x35x7 oil seal, consider

1. Material Oil seals are made from various materials, including rubber, silicone, and polyurethane. The choice of material affects temperature resistance, chemical compatibility, and physical durability.

2. Design Features Different designs feature varying lip configurations and spring-loaded options. Understanding the specific needs of the application can guide the selection process.

3. Operating Conditions Consider factors such as temperature ranges, exposure to chemicals, and the speed of rotating parts. These conditions greatly influence the choice of the most suitable oil seal.

4. Manufacturer Specifications Always refer to the manufacturer's guidelines and specifications for installation and replacement to ensure proper sealing and avoid future failures.

Conclusion

The 25x35x7 oil seal serves as a critical component in numerous industries, ensuring the efficiency and longevity of mechanical systems. By preventing leaks and protecting against contaminants, this oil seal plays an invaluable role in maintaining optimal performance and enhancing the lifespan of machinery. When selecting and installing an oil seal, it is essential to consider factors such as material and design to achieve the best results. Ultimately, investing in high-quality oil seals is a proactive measure that can save time, reduce costs, and enhance performance across various applications.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories