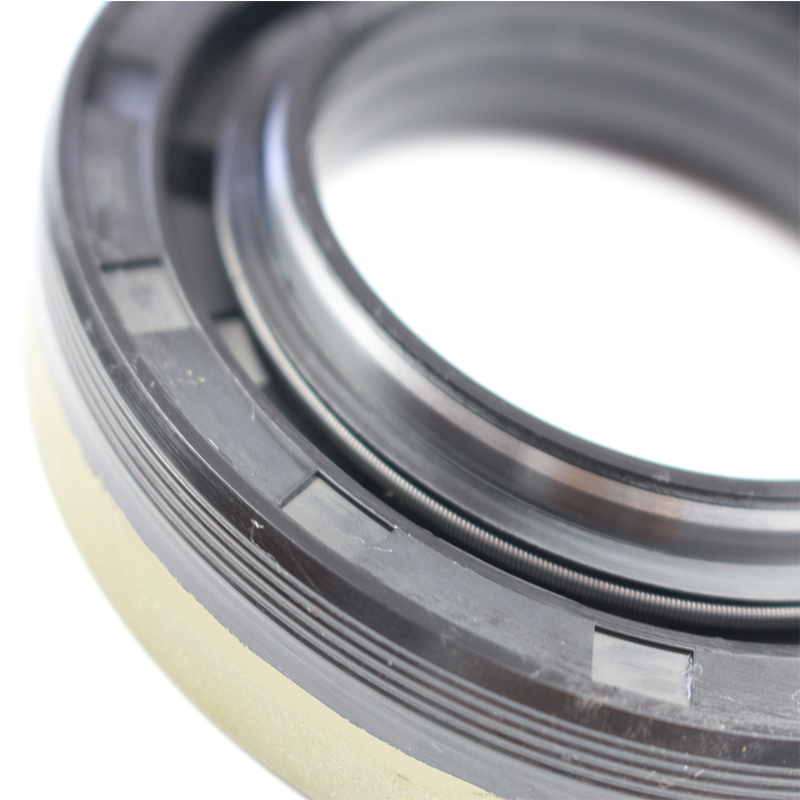

25 47 7 oil seal

Understanding the 25% 2047 7 Oil Seal Importance, Applications, and Maintenance

Oil seals, often referred to as shaft seals or lip seals, play a crucial role in various mechanical systems by preventing the leakage of oils and other fluids. Among the myriad of oil seals available on the market, the 25% 2047 7 oil seal stands out due to its specific functionalities and applications. In this article, we will delve into the details of this particular oil seal, its significance, applications, and tips for maintenance.

What is an Oil Seal?

An oil seal is a mechanical seal that is used to retain lubricant in a housing. It comprises a rubber or elastomeric material that forms a snug fit around a rotating or stationary shaft. The primary function of an oil seal is to prevent the escape of lubricating oil and to keep contaminants, such as dust and dirt, from entering the machinery. This not only prolongs the life of the equipment but also enhances its performance.

Characteristics of the 25% 2047 7 Oil Seal

The designation “25% 2047 7” typically refers to specific dimensions and materials used in the manufacture of the oil seal. The first part, “25%”, may indicate the percentage of specific materials incorporated in the seal's composition, contributing to its durability and flexibility. The “2047” could signify the seal's width or inner/outer diameter, providing precise fitting for different applications. Finally, the “7” may denote the specific series or model number used by the manufacturer, ensuring easy identification and replacement.

One of the key attributes of the 25% 2047 7 oil seal is its resistance to high temperatures and pressures, making it suitable for demanding environments. Its design typically includes a metal shell that reinforces its structure, providing additional strength and thermal stability, while the elastomer material ensures a proper seal around the rotating component.

Applications

Oil seals, including the 25% 2047 7, find extensive use across various industries due to their reliable sealing properties. Here are some common applications

1. Automotive Industry Oil seals are widely used in automobiles to prevent oil leaks from engines, transmissions, and differential systems. The 25% 2047 7 oil seal is particularly useful in high-performance vehicles requiring precise sealing to maintain optimal lubrication.

2. Industrial Machinery In industrial settings, machinery often operates under extreme conditions, including high speeds and harsh environments. The robustness of the 25% 2047 7 oil seal makes it an excellent choice for manufacturing equipment, pumps, and compressors.

25 47 7 oil seal

3. Agricultural Equipment Agricultural machinery, which often operates in muddy or dusty conditions, benefits significantly from oil seals that can effectively keep contaminants at bay, ensuring smooth operation.

4. Marine Applications In marine environments, preventing water ingress is crucial. Oil seals like the 25% 2047 7 are commonly used in pumps and throttles to maintain integrity underwater.

Maintenance and Replacement

Maintaining oil seals is essential to ensure longevity and prevent unexpected failures. Here are some key maintenance tips

- Regular Inspection Regularly check for signs of wear and tear, such as cracks or deformation in the rubber material. Early detection can prevent costly breakdowns.

- Lubrication Ensure that the seals remain adequately lubricated. Dry seals can become brittle and fail, leading to leaks.

- Proper Installation When replacing an oil seal, ensure that it is installed correctly. An incorrect fit can compromise its sealing capabilities and result in failure.

- Temperature Management Monitor operating temperatures, as excessive heat can damage the oil seal material over time. In some cases, using a seal with higher temperature resistance can be beneficial.

- Replacement Oil seals wear out over time and will need replacement. It’s essential to use the correct specifications, such as those represented by the 25% 2047 7 designation, to ensure compatibility and function.

Conclusion

The 25% 2047 7 oil seal exemplifies the importance of choosing the right sealing solution for various mechanical applications. Its unique characteristics, adaptability, and durability make it a reliable choice across industries. By understanding its applications and adhering to proper maintenance practices, one can enhance equipment performance and longevity while preventing costly leaks and breakdowns. As technology continues to evolve, so too will the designs and materials used in oil seals, providing even more reliable solutions for the challenges faced in various environments.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories