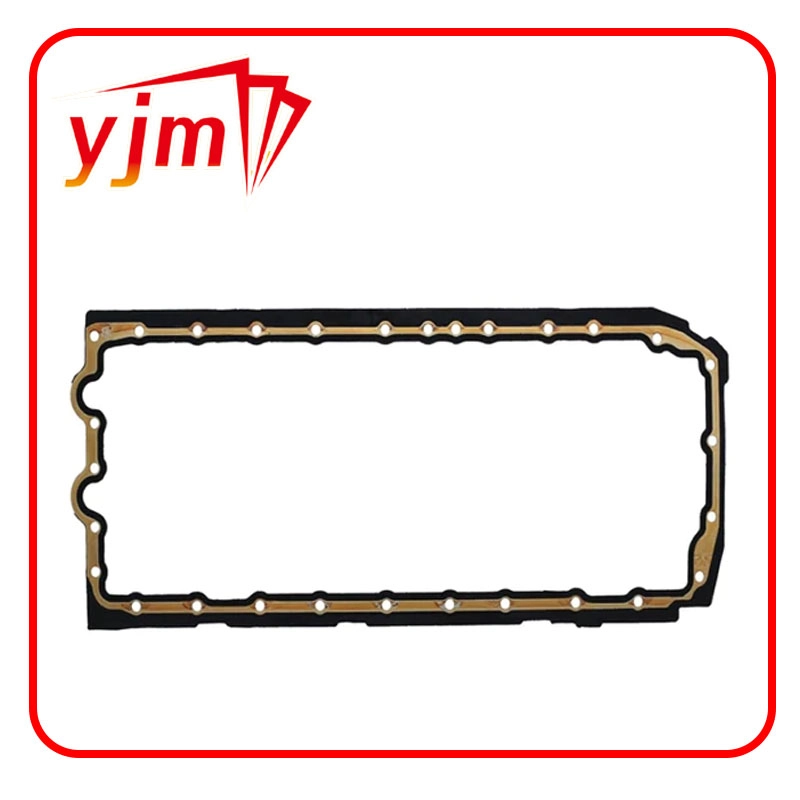

25 47 7 oil seal

Understanding the 25% 2047 7 Oil Seal A Comprehensive Overview

In the realm of mechanical components, oil seals play a pivotal role in ensuring the smooth and efficient operation of machinery. Among the myriad of oil seals available in the market, the 25% 2047 7 oil seal stands out due to its unique specifications and versatile applications. This article explores its components, functions, materials, and significance in various industries.

What is an Oil Seal?

An oil seal, often referred to as a fluid seal, is a device used to prevent the leakage of lubricants and protect machinery from dust, dirt, and moisture. It serves as a barrier, ensuring that the oil remains contained within the machinery, which is essential for optimal performance and longevity.

Breakdown of the 25% 2047 7 Oil Seal

The designation 25% 2047 7 provides insights into the specific characteristics of this oil seal. The 25% often indicates a particular design feature or sealing capability, which allows it to perform effectively under specific conditions. The numbers that follow typically relate to dimensions or material specifications that define its fit and performance metrics.

- Size and Dimensions The numerical values in the designation often correspond to the seal's size, such as inner diameter, outer diameter, and width. Understanding these dimensions is critical for selecting the right oil seal for a specific application.

- Material Composition Oil seals can be made from various materials, including rubber, silicone, and thermoplastic elastomers. The choice of material affects the seal's durability, temperature tolerance, and resistance to chemical exposure. The 25% 2047 7 oil seal is likely crafted from a high-quality material that withstands high pressures and variable environmental conditions.

Applications of the 25% 2047 7 Oil Seal

25 47 7 oil seal

The versatility of the 25% 2047 7 oil seal enables its use across various industries, including

- Automotive In vehicles, oil seals prevent leaks in engine components and transmission systems, ensuring efficient operation and fuel economy.

- Industrial Machinery In manufacturing and heavy machinery, oil seals protect gears and bearings, preventing contamination and maintaining lubrication. This is crucial for reducing wear and tear and ensuring the reliability of equipment.

- Aerospace In the aerospace sector, oil seals are essential for maintaining the integrity of systems under extreme conditions, such as high pressures and fluctuating temperatures.

- Marine Applications Oil seals are also vital in marine equipment, where they prevent seawater ingress and oil leaks in engines and gearboxes.

Importance of Selecting the Right Oil Seal

Choosing the appropriate oil seal is paramount for any machinery's performance and lifespan. An unsuitable oil seal can lead to leaks, contamination, and ultimately, mechanical failure. Factors to consider include compatibility with lubricants, environmental conditions, and the specific application requirements.

Conclusion

The 25% 2047 7 oil seal illustrates the intricacies involved in selecting and utilizing mechanical components for optimal machinery performance. Its design and material composition make it suitable for a range of demanding applications. Understanding the importance of oil seals, such as the 25% 2047 7, is essential for engineers, mechanics, and hobbyists who aim to ensure operational efficiency and extend the life of their machinery. In the fast-paced world of industrial applications and vehicle performance, every component counts, and oil seals like the 25% 2047 7 are vital in keeping operations running smoothly.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories