Understanding the Importance of 22% 40% 7% Oil Seal Performance in Industrial Applications

Understanding the 22% 40% 7% Oil Seal A Comprehensive Insight

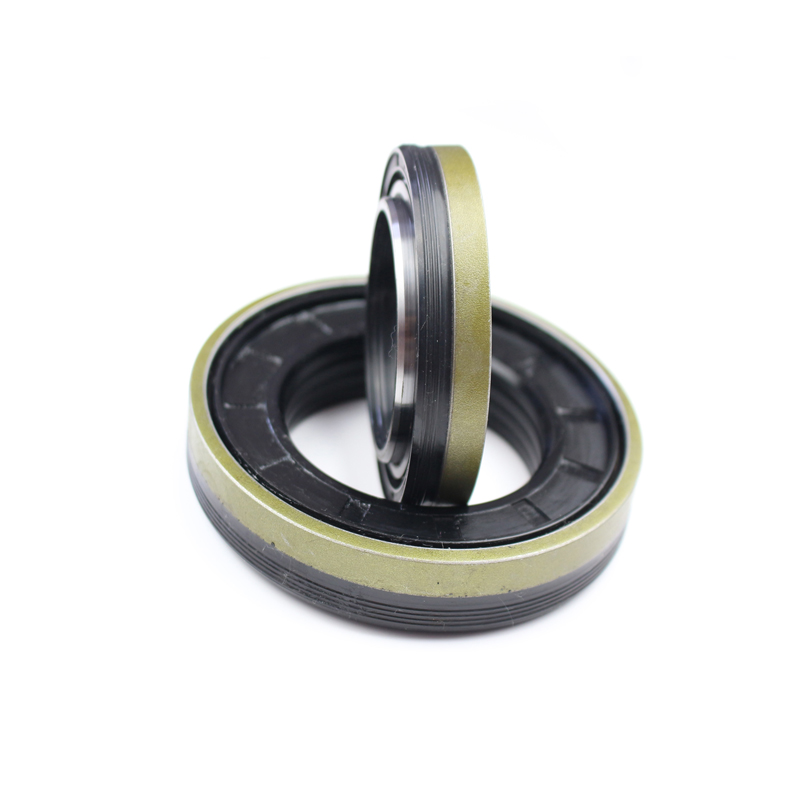

In the world of mechanical engineering and manufacturing, oil seals play an essential role in ensuring the smooth operation of machinery. One particular specification that often arises in discussions about oil seals is the 22% 40% 7% designation. This article delves into the significance of this designation, the role of oil seals in machinery, and the implications of these percentages in real-world applications.

What is an Oil Seal?

An oil seal, also known as a fluid seal, is designed to retain lubricant and exclude dirt and other contaminants from entering the inner workings of machinery. This simple yet crucial component acts as a barrier, providing a seal between moving and stationary parts, thereby preventing leakage and protecting internal mechanisms.

Oil seals are utilized in various applications, including automotive engines, industrial machinery, and household appliances. Their effectiveness in maintaining the integrity of lubricants significantly boosts operational efficiency and extends the lifespan of equipment.

Decoding the 22% 40% 7% Designation

The numbers in the 22% 40% 7% designation often refer to specific characteristics of the oil seal, such as material composition, size specifications, or the proportions of different functions—a focus on performance, durability, and resistance to environmental factors.

1. Material Composition The first percentage, 22%, may indicate the proportion of a particular material used in manufacturing the oil seal. For instance, it could refer to the percentage of rubber or other composites combined to create an oil-resistant seal. The choice of materials directly affects the seal's performance characteristics, including flexibility, temperature resistance, and durability.

2. Design Specifications The second percentage, 40%, might pertain to the design or dimensional proportions of the seal. This could encompass the diameter of the seal or the thickness of specific components within the seal structure. Proper sizing is critical to ensure that the oil seal fits snugly in its designated space, preventing any fluid from escaping.

22 40 7 oil seal

3. Performance Metrics The final percentage, 7%, could refer to a performance metric, such as the maximum allowable wear rate or a measure of the seal's long-term reliability under specified operating conditions. A lower percentage here often indicates a higher performance standard, suggesting that the oil seal can endure harsh conditions while successfully performing its sealing function.

Importance in Various Industries

The 22% 40% 7% oil seal is vital to a variety of industries, particularly where machinery operates under demanding conditions. In automotive applications, oil seals help prevent engine oil from leaking, which is essential for maintaining engine lubricity and efficiency. In industrial machinery, these seals reduce downtime caused by fluid leaks, thereby maximizing productivity.

Additionally, oil seals are crucial in the aerospace and marine industries, where they must withstand extreme temperatures and pressures. The reliability of these seals directly impacts safety and performance, making the correct specification a top priority for engineers and manufacturers.

Conclusion

The 22% 40% 7% oil seal designation encapsulates various critical aspects of oil seal technology. Understanding the importance of this designation can assist engineers and procurement specialists in making informed decisions about oil seal selection and application.

When considering the role of oil seals within machinery, it's clear that even the smallest components play a critical role in overall system efficiency and integrity. The analysis of the 22% 40% 7% designation in oil seals highlights the intricate balances of material properties, design, and performance criteria that must be maintained to ensure optimal functioning of machinery across diverse industries.

As technology continues to evolve, advancements in material science and engineering techniques will no doubt lead to even more sophisticated oil seals, providing enhanced performance and durability to meet the ever-increasing demands of modern machinery.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories