20 30 7 oil seal

Understanding the 20-30-7 Oil Seal A Comprehensive Overview

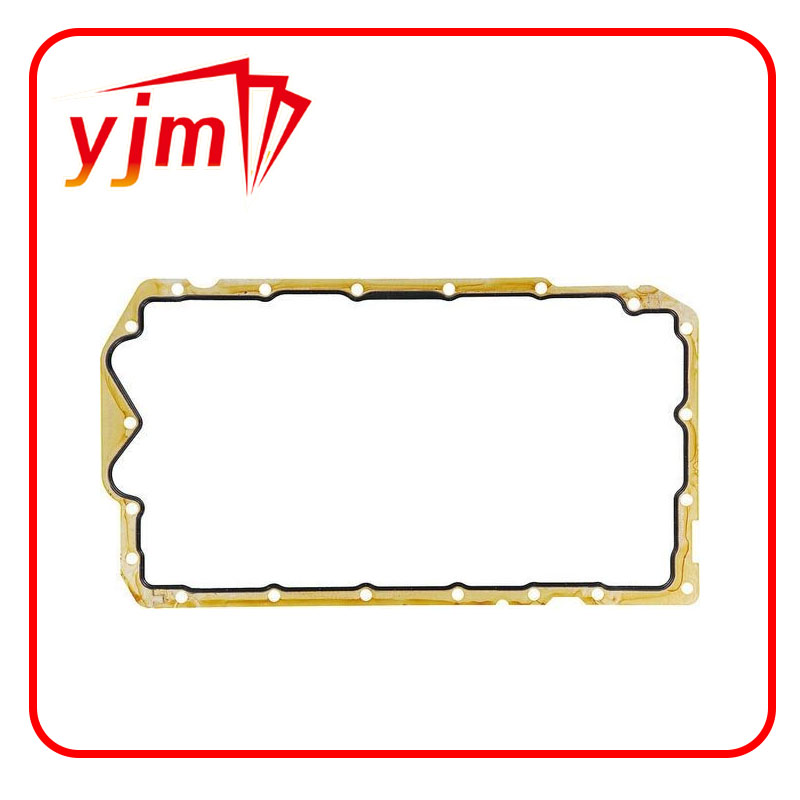

Oil seals are critical components in various mechanical systems, providing a crucial barrier against the leakage of lubricants and the entry of contaminants. Among the numerous specifications of oil seals, the 20-30-7 oil seal stands out for its unique dimensions and applications. This article aims to delve into the details of the 20-30-7 oil seal, its significance, construction, and typical applications.

What is a 20-30-7 Oil Seal?

The designation 20-30-7 refers to the dimensional specifications of the oil seal. The first number, 20, denotes the inner diameter in millimeters; the second number, 30, indicates the outer diameter, and the third number, 7, represents the width or thickness of the seal. In simple terms, the 20-30-7 oil seal is designed to fit within a bore of 20 mm, sealing an outer diameter of 30 mm, with a width of 7 mm. These seals are typically made from materials such as rubber or synthetic polymers, which provide excellent resilience and sealing capabilities.

The Importance of Oil Seals

Oil seals play a vital role in maintaining the performance and longevity of machinery. By preventing the escape of lubricants, they help to reduce friction and wear between moving parts, enhancing the overall efficiency of mechanical systems. Moreover, oil seals also protect against dirt, dust, and moisture from entering the machinery, which could lead to contamination and failure. In effect, oil seals contribute significantly to the operational reliability of engines, gearboxes, and hydraulic systems.

Key Features of the 20-30-7 Oil Seal

1. Material Composition The most commonly used materials for oil seals include nitrile rubber (NBR), fluoroelastomer (FKM), and silicone rubber. NBR is widely preferred due to its excellent oil resistance and temperature tolerance, making it suitable for various industrial applications.

20 30 7 oil seal

2. Design A typical 20-30-7 oil seal features a lip design that creates a tight seal against the shaft, effectively preventing oil leakage. The lip can be either single or double, depending on the level of sealing required. A double-lip design offers an extra layer of protection against contaminants.

3. Temperature and Pressure Ratings Oil seals are designed to operate under varying temperature and pressure conditions. The specifications of the 20-30-7 seal will generally provide a temperature range of -20°C to 100°C, though some advanced materials can withstand even higher temperatures.

4. Applications The versatility of the 20-30-7 oil seal allows it to be used in a myriad of applications. Common uses include automotive engines, pump assemblies, gearboxes, and hydraulic cylinders. In addition, they are often found in industrial machinery where lubrication is crucial for optimal performance.

Installation and Maintenance

Proper installation is essential for the effectiveness of any oil seal. It's important to ensure the sealing surface is clean and free from damage before installation. Misalignment can lead to premature wear and failure, so precise alignment during installation is crucial. Regular inspection and maintenance help in identifying wear and potential leaks early, allowing for timely replacements and reducing the risk of system failures.

Conclusion

The 20-30-7 oil seal plays an indispensable role in various machinery and automotive applications, providing effective sealing solutions that contribute to the smooth operation and longevity of mechanical systems. Understanding its specifications, materials, and applications can facilitate informed decisions in selecting the right oil seal for specific needs. Whether in industrial machinery, automotive components, or hydraulic systems, the 20-30-7 oil seal is a reliable choice that ensures optimal performance and protection. By recognizing its importance and adhering to proper installation and maintenance practices, users can ensure the durability and efficiency of their machinery for years to come.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories