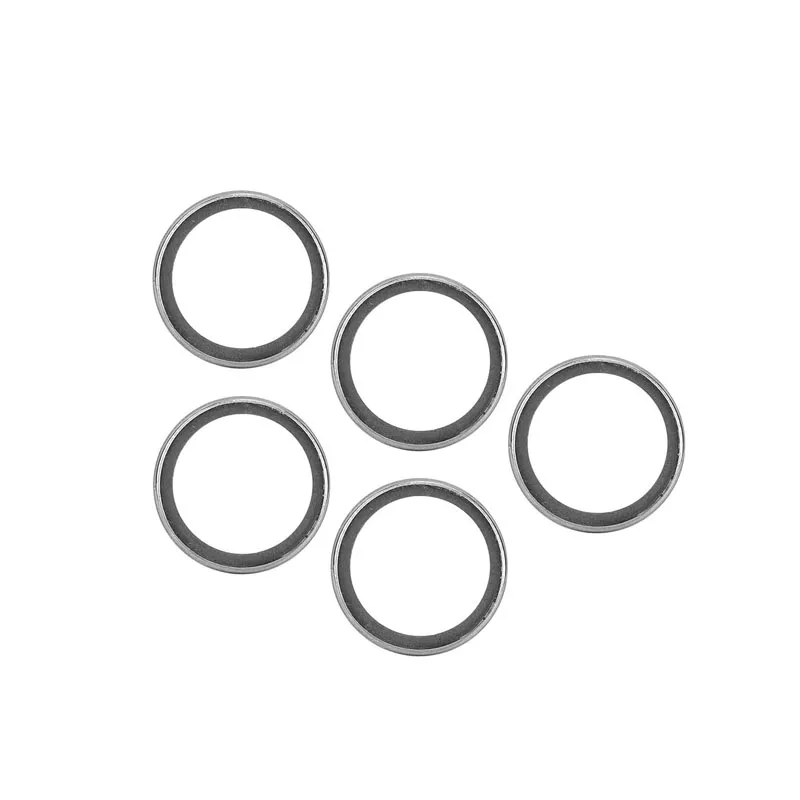

17mm oil drain plug

The Importance of the 17mm Oil Drain Plug A Comprehensive Guide

When it comes to regular vehicle maintenance, one of the most overlooked components is the oil drain plug. Among various sizes, the 17mm oil drain plug plays a crucial role in ensuring the healthy functioning of an engine. This article will explore the significance of the 17mm oil drain plug, its features, and how to maintain it effectively.

Understanding the Oil Drain Plug

The oil drain plug is a small but essential part located at the bottom of the oil pan, typically secured tightly to prevent leakage. Its primary function is to provide a means to remove engine oil during oil changes. Specifically, the 17mm oil drain plug refers to the size of the wrench needed to loosen or tighten it, usually found in many automobile models, especially those produced by certain Asian and European manufacturers.

Importance of the Right Size

Using the right size drain plug is critical. A 17mm oil drain plug is designed to create a specific fit that enhances the seal and prevents leaks. If the plug is too small, it won't create a proper seal, leading to potential oil leaks that can cause significant engine damage over time. Conversely, using a plug that is too large could damage the threads of the oil pan, resulting in costly repairs.

Features of the 17mm Oil Drain Plug

1. Material Most oil drain plugs, including the 17mm variant, are made from materials such as steel or aluminum. These materials are chosen for their strength and resistance to oil corrosion.

2. Washer Many 17mm oil drain plugs come with a built-in washer or a crush washer. This feature aids in achieving a tighter seal, reducing the likelihood of leaks. It is essential to replace this washer during an oil change to ensure a secure fit.

3. Thread Design The threading on the 17mm oil drain plug is designed to match that of the oil pan. Proper threading ensures that during the installation, the plug seats correctly, maintaining the integrity of the oil system.

Maintenance Tips

17mm oil drain plug

To ensure the longevity and functionality of your 17mm oil drain plug, consider the following maintenance tips

1. Regular Inspections Periodically check the drain plug for signs of wear or damage. Look for cracks, stripped threads, or corrosion, which may require a replacement.

2. Proper Torque When installing or reinstalling the drain plug, ensure it is tightened to the manufacturer’s recommended torque specifications. Over-tightening can lead to stripping threads or damaging the washer.

3. Oil Changes Always replace the drain plug washer during an oil change. This simple step can prevent leaks and prolong the life of your engine.

4. Use Quality Oil Quality engine oil can reduce sludge buildup and extend the intervals between oil changes, thereby reducing wear and tear on the oil drain plug.

5. Monitor Oil Levels Keep an eye on your oil levels. If you notice a drop without any apparent leaks, the drain plug might need attention, or there may be another underlying issue.

Common Issues to Avoid

While the 17mm oil drain plug is generally a sturdy component, there are some issues that can arise. Stripping the threads is one of the most common concerns, often caused by over-tightening. If this occurs, a thread repair can be complex and costly. Additionally, failing to replace the washer can lead to leaks, while using an incorrect size drain plug could compromise the entire lubrication system.

Conclusion

The 17mm oil drain plug may seem like a minor component of vehicle maintenance, but its importance cannot be overstated. It plays a pivotal role in the health and performance of the engine. By understanding its significance, maintaining it properly, and ensuring you have the right tools and parts, drivers can protect their engines and enhance the overall longevity of their vehicles. Regular maintenance, vigilance, and timely replacements will keep your engine running smoothly for years to come.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories