Choosing the Right 16mm Sump Plug for Efficient Drainage Solutions

Understanding the 16mm Sump Plug Importance and Maintenance

The 16mm sump plug, a small but significant component in various machinery, particularly in automotive and industrial applications, plays a crucial role in the maintenance of oil reservoirs or sumps. Understanding its function, construction, and maintenance procedures can help ensure the longevity and optimal performance of equipment.

What is a Sump Plug?

A sump plug is a device used to seal the bottom of a sump or oil reservoir. By providing a secure closure, it prevents any oil or fluids from leaking out of the system. The 16mm size designation refers to the diameter of the plug itself, commonly threaded to fit into the designated opening of the sump. This standard size makes it easy to find compatible replacements in the market.

Material and Design

Typically, sump plugs are made from durable materials such as steel or aluminum. Some are coated with protective substances to resist corrosion, particularly in environments where moisture and contaminants are prevalent. The design usually incorporates a washer, which helps ensure a tighter seal, reducing the risk of leaks. In addition, some sump plugs come with built-in magnetic features to collect metal shavings, further protecting the machinery from wear.

Importance of the Sump Plug

The sump plug plays a pivotal role in maintaining the integrity of the oil system. Proper sealing prevents oil leakage, which can lead to low oil levels, resulting in insufficient lubrication of engine parts. This could ultimately cause severe damage or total engine failure. Moreover, leaks can create hazards, such as slippery surfaces in industrial settings or environmental issues if fluids seep into the ground or waterways.

In addition to preventing leaks, the sump plug also facilitates oil changes. When it’s time to replace the oil in a vehicle or machine, the sump plug can be removed. This allows the old, used oil to drain out completely. Properly draining the oil ensures that the new oil can perform effectively, maintaining the machinery’s efficiency.

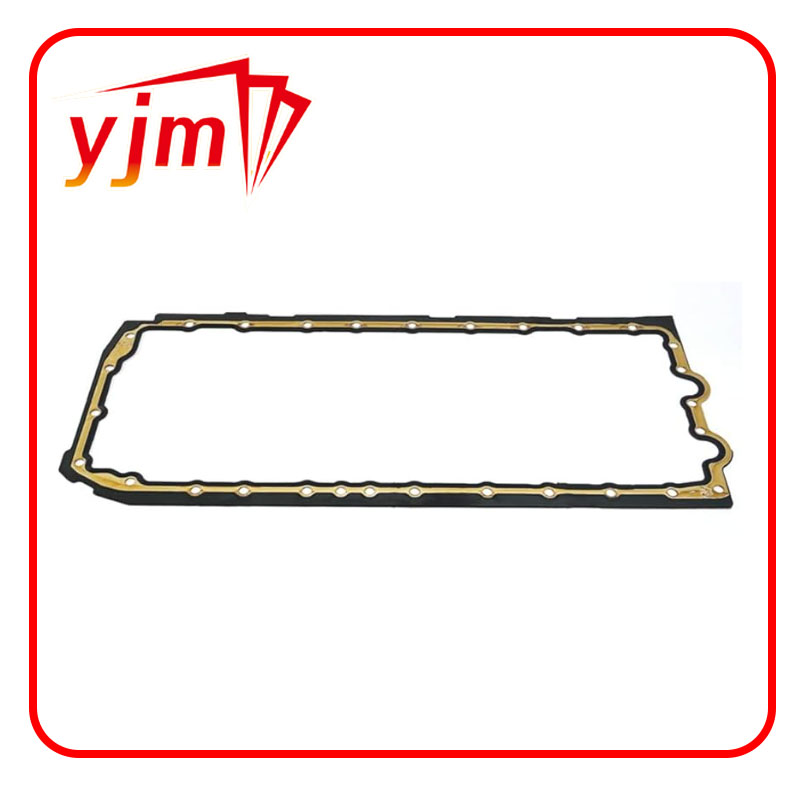

16mm sump plug

Maintenance Tips

Maintaining the sump plug and its surrounding area is essential for long-term functionality. Here are some important maintenance tips

1. Regular Inspection Frequently check the sump plug for signs of wear or damage. Cracks, rust, or threads that appear worn may indicate that it's time for a replacement.

2. Tightening Ensure that the plug is tightened to the manufacturer's specifications. Over-tightening can break the threads, while under-tightening may lead to leaks.

3. Replace the Washer Each time the sump plug is removed for an oil change, consider replacing the washer. Old washers can become compressed or worn out, undermining their effectiveness.

4. Check for Leaks After replacing the sump plug, monitor the area for leaks to ensure that the seal is secure.

5. Use Quality Oil Good-quality lubricants not only improve performance but also help reduce debris and contaminants that can affect the seal around the sump plug.

Conclusion

The 16mm sump plug may seem like a minor mechanical component, but its significance cannot be overstated. Proper maintenance and understanding of its function contribute directly to the overall health of an engine or machinery. By regularly inspecting and maintaining this crucial part, equipment operators can prevent costly repairs and ensure optimal performance over the machinery's lifespan. Remember, a small part can make a big difference!

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories