14x24x6 Oil Seal Specifications and Compatibility for Optimal Performance

Understanding the 14x24x6 Oil Seal Importance, Types, and Applications

Oil seals are critical components in various mechanical systems, ensuring that lubricants remain contained and that contaminants are kept out. Among the vast range of oil seals available, the 14x24x6 oil seal is notable for its specific dimensions and applications. In this article, we will explore what makes this oil seal important, the types available, and how it is utilized across different industries.

What is an Oil Seal?

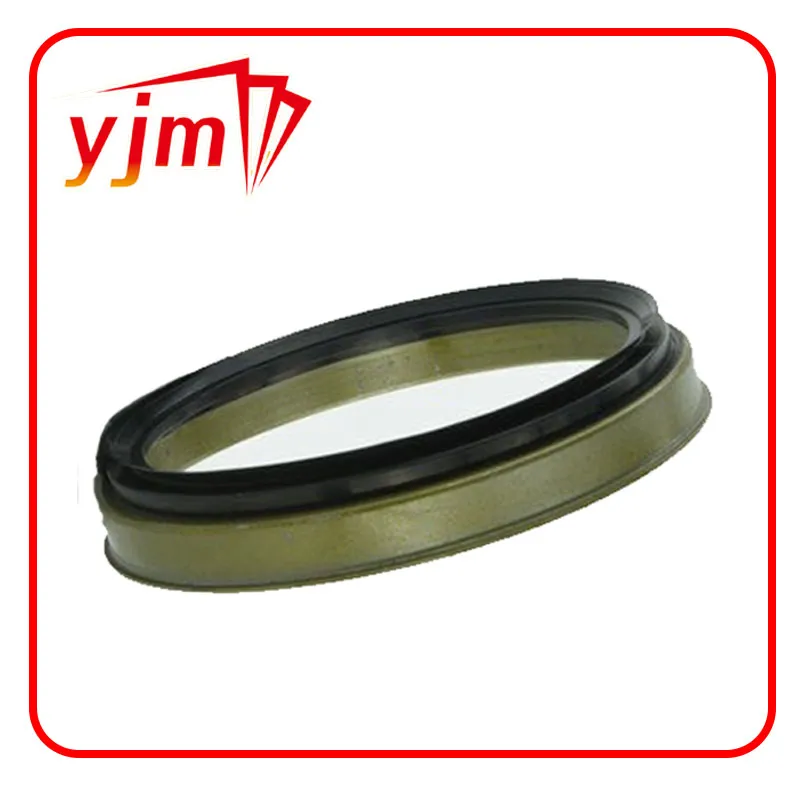

An oil seal, also known as a lip seal or rotary seal, is designed to seal the interface between a stationary and a rotating component. It consists of a rubber lip that fits against the shaft, preventing lubricant leakage while also preventing dirt, dust, and other contaminants from entering. The designation of 14x24x6 refers to the seal's inner diameter (14 mm), outer diameter (24 mm), and width (6 mm). These dimensions make the 14x24x6 oil seal suitable for a variety of applications where precise sealing is required.

Importance of the 14x24x6 Oil Seal

The effectiveness of an oil seal like the 14x24x6 is pivotal in maintaining the longevity and reliability of mechanical systems. The primary functions include

1. Contamination Prevention By forming a tight seal, the oil seal prevents dust, dirt, and other contaminants from entering the machinery, which can lead to wear and damage over time.

2. Lubrication Retention The seal prevents the escape of lubricating oil, ensuring that moving parts remain adequately lubricated, thereby reducing friction and heat generation.

3. Efficiency Maintenance By keeping lubrication where it is needed, oil seals contribute to the overall efficiency of machines, positively affecting performance and energy consumption.

4. Cost Reduction By preventing leaks and contamination, the use of oil seals can lead to reduced maintenance costs and decreased downtimes, enhancing productivity.

Types of 14x24x6 Oil Seals

Oil seals come in various materials and designs, tailored for specific applications and environments. Some common types of oil seals that share the 14x24x6 dimensions include

14x24x6 oil seal

- Nitrile Rubber Seals Known for their excellent resistance to petroleum-based oils, nitrile rubber seals are popular in automotive and industrial applications.

- Fluoroelastomer Seals These are used in more aggressive environments, offering resistance to high temperatures and a wide range of chemicals, making them suitable for specialized industrial applications.

- Polyurethane Seals Renowned for their wear resistance, these seals are often used in situations where durability is paramount, such as in construction or heavy machinery.

- Metal-encased Seals These seals incorporate a metal casing for added robustness in demanding environments, offering additional protection against mechanical damage and deformation.

Applications of the 14x24x6 Oil Seal

Given its dimensions and properties, the 14x24x6 oil seal finds applications in numerous industries

- Automotive Used in engines, gearboxes, and differentials, these seals ensure that oil remains contained and functional components are kept free from contaminants.

- Industrial Machinery Found in various rotating equipment, such as pumps and motors, where maintaining lubrication is critical to performance and longevity.

- Agricultural Machinery Many farming implements rely on oil seals to operate efficiently, especially those with moving parts subjected to different environmental conditions.

- Aerospace In aircraft engines and hydraulic systems, the reliability of oil seals is essential for safety and performance.

Conclusion

The 14x24x6 oil seal may seem like a small component, but its role in machinery cannot be overstated. By providing effective sealing solutions, these oil seals enhance performance, protect against contamination, and ultimately contribute to the operational efficiency of various industries. Understanding the importance, types, and applications of oil seals can aid in selecting the right one for your needs, ensuring reliable and efficient machinery operation. In a world where every part counts, investing in quality oil seals is an investment in the longevity and productivity of mechanical systems.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories