14mm Sump Plug Washer Replacement Guide for Optimal Engine Performance

Understanding the Importance of a 14mm Sump Plug Washer

When it comes to maintaining your vehicle, small components can have a significant impact on performance and durability. One such component that often goes overlooked is the sump plug washer, particularly the 14mm size. This seemingly minor part plays a critical role in ensuring the integrity of your vehicle’s oil system. In this article, we’ll discuss what a sump plug washer is, why the 14mm size is commonly used, and how to properly maintain this essential item.

What is a Sump Plug Washer?

A sump plug washer is a small but vital component that sits between the engine oil sump plug and the engine’s oil pan. Its function is to create a tight seal that prevents oil leaks from occurring. When you drain your engine oil, removing the sump plug is necessary, and this is where the washer comes into play. As the plug is tightened, the washer compresses, ensuring that no oil seeps out under pressure or as the engine operates.

The Significance of Size Why 14mm?

The size of the sump plug washer is crucial for its effectiveness. The 14mm sizing is popular among many automotive applications due to standardization in many engine designs. Using the correct size is essential for the washer to fit properly and form the necessary seal. If you use a washer that is too large or too small, it may not provide an adequate seal, resulting in leaks, which can lead to a host of problems, including engine damage or even failure.

Common Materials Used

Sump plug washers come in various materials, each with unique properties that affect performance. Common materials include

1. Copper Known for its excellent thermal and electrical conductivity, copper washers are fairly common. They can withstand high temperatures and maintain their shape over time, making them a reliable choice for many engines.

2. Aluminum Lightweight and resistant to corrosion, aluminum washers are also popular. They provide a good seal but may not be suitable for extremely high-temperature applications.

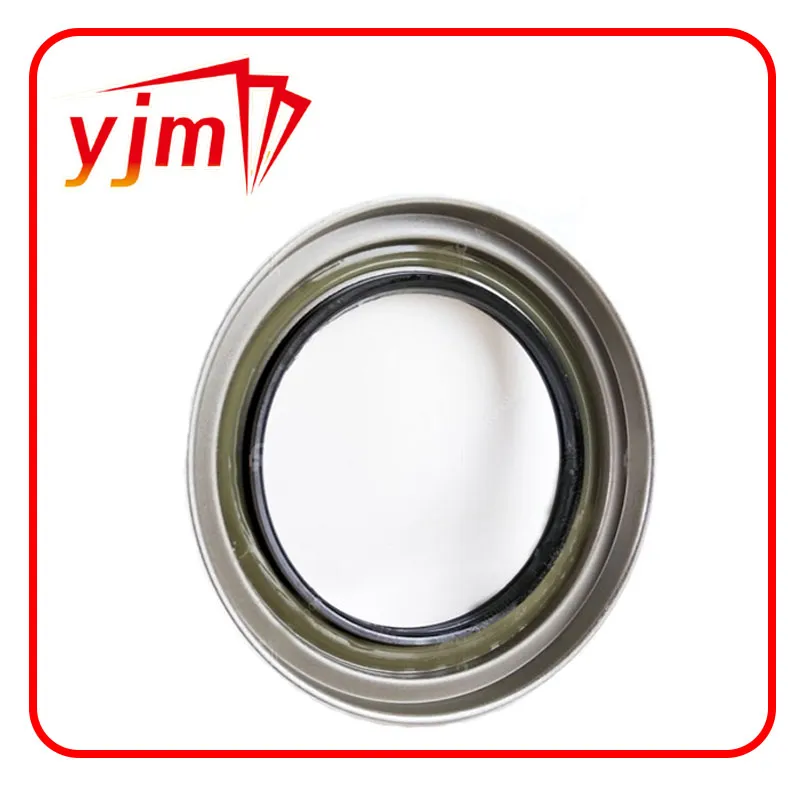

14mm sump plug washer

3. Rubber or Composite Some washers are made from rubber or composite materials. These provide excellent sealing properties and are often used in applications where a higher level of flexibility is required.

Choosing the right material for your sump plug washer can greatly affect the longevity and effectiveness of your engine oil management system

.Maintenance Tips

To ensure that your sump plug washer performs optimally, consider the following maintenance tips

1. Regular Inspection Check the condition of the washer each time you change your oil. Look for cracks, deformation, or signs of wear. If any damage is present, it’s time to replace the washer.

2. Replace After Every Oil Change It is a good practice to replace the sump plug washer every time you change your oil. This ensures a fresh seal and reduces the risk of leaks.

3. Clean the Surface Before installing a new washer, clean both the sump and the plug surfaces. Any debris or old oil can prevent a proper seal, leading to leaks.

4. Do Not Over-Tighten While it’s important to ensure a tight seal, over-tightening the sump plug can deform the washer and lead to leaks. Follow the manufacturer’s specifications for torque settings.

Conclusion

The 14mm sump plug washer may seem like a trivial component in the grand scheme of automotive maintenance, but it is a fundamental part that ensures the proper functioning of your engine's oil system. By understanding the importance of this washer, choosing the right size and material, and following proper maintenance practices, you can help extend the lifespan of your vehicle's engine and avoid costly repairs down the line. Regular attention to this small yet essential component can lead to a more efficient and reliable vehicle, ultimately enhancing your driving experience.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories