12mm Drain Plug Washer for Optimal Sealing and Leak Prevention Solutions

The Importance of 12mm Drain Plug Washers A Small but Mighty Component

In the world of plumbing and automotive maintenance, there are many components that play a critical role in ensuring systems function properly. Among these, the 12mm drain plug washer often goes unnoticed. However, this small yet essential item is a crucial element in preventing leaks, ensuring proper drainage, and maintaining the overall efficiency of various systems, from vehicles to household plumbing.

Understanding the Role of Drain Plug Washers

A drain plug washer is a flat, ring-shaped piece that sits between the drain plug and the surface of the draining component, such as an oil pan or a sink. Its primary function is to create a watertight seal, preventing fluid from leaking out. This is particularly important in systems where maintaining fluid levels is essential for optimal performance. For example, in automotive applications, an oil drain plug washer ensures that oil stays where it belongs in the engine.

The Evolution of Drain Plug Washers

Historically, drain plug washers have been made from various materials, including rubber, metal, and composite materials. Each type offers different advantages depending on the application. Rubber washers tend to provide excellent sealing capabilities and flexibility, accommodating slight imperfections in mating surfaces. Metal washers, on the other hand, are typically used in high-temperature or high-pressure applications, where durability is paramount.

The 12mm size is standard for many applications, making it a widely used component in both automotive and plumbing scenarios. The choice of a 12mm washer is based on the size of the drain plug it is meant to accompany, ensuring compatibility and effectiveness.

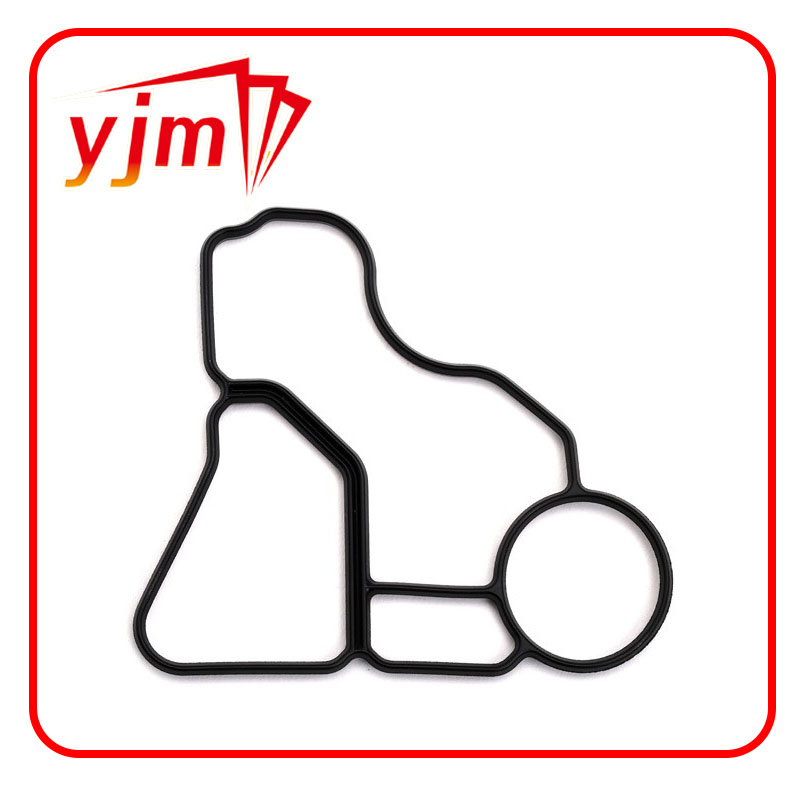

12mm drain plug washer

Why Quality Matters

When it comes to drain plug washers, the quality of the material and manufacturing process is crucial. A low-quality washer can lead to leaks, which in turn can cause significant damage to systems and create hazardous spills. In automotive settings, for instance, a leaking oil drain plug can lead to oil loss, impacting engine performance and leading to potentially costly repairs. In plumbing, leaks can result in water damage, mold growth, and increased utility bills.

Investing in high-quality 12mm drain plug washers made from durable materials can save time and money in the long run. Many manufacturers now offer washers designed to withstand harsh conditions, including extreme temperatures and chemical exposure. These washers provide a reliable seal, extending the lifespan of the components they protect.

The Installation Process

Installing a 12mm drain plug washer is a straightforward process, but attention to detail is essential. Before installing a new washer, it’s advisable to clean the mating surfaces thoroughly to remove any debris or old sealing material. This ensures a tight seal and reduces the risk of leaks. Once the area is clean, the washer should be placed on the drain plug, which is then screwed into the assembly. Properly tightening the drain plug is crucial, as overtightening can damage the washer or the components involved.

Conclusion

While it may be just a small component, the 12mm drain plug washer plays an outsized role in the functionality and reliability of various systems. From automotive engines to household plumbing, ensuring that high-quality washers are used and properly installed can prevent leaks and prolong the life of equipment. Whether you are a DIY enthusiast or a professional mechanic, never underestimate the importance of this little piece of hardware. Investing in a reliable drain plug washer is a simple yet effective way to ensure that systems remain leak-free and function at their best.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories