Different Varieties of Oil Seals for Various Industrial Applications

Understanding the Various Types of Oil Seals

Oil seals are crucial components in many mechanical systems, playing a vital role in preventing fluid leaks and protecting machinery from contamination. These seals are designed to retain lubricants within a component while also keeping dirt and moisture out, ensuring smooth operation and longevity of equipment. This article explores the various types of oil seals, their construction, applications, and the benefits they provide.

What is an Oil Seal?

An oil seal, also known as a radial lip seal or oil gasket, is a mechanical device that seals the closure between components of a machine, allowing for rotary movement while preventing fluid from leaking. The basic construction of an oil seal includes a rubber sealing lip, a metal case for structural integrity, and sometimes a spring to ensure consistent contact with the sealed surface.

Types of Oil Seals

1. Rotary Oil Seals These are the most common type of oil seal, designed to fit around rotating shafts. They are widely used in applications such as automotive engines, gearboxes, and hydraulic systems. Rotary oil seals typically feature a lip that presses against the rotating shaft, providing an effective barrier against oil leakage.

2. Static Oil Seals Unlike rotary seals, static oil seals are used in applications where there is no relative motion between the sealing surfaces. These seals are often found in flanges, pipe joints, and housing covers. Made from rubber or other elastomeric materials, static seals provide high resistance to fluid leakage under static loads.

3. V-Rings V-rings are a specialized type of oil seal featuring a flexible lip that is designed to fit onto a rotating shaft while sealing against a stationary component. These are particularly advantageous in high-speed applications or environments with abrasive contaminants.

4. U-Cups U-cups are designed for specific applications that require stronger sealing capabilities. Their shape allows them to provide excellent sealing performance against high-pressure fluids while accommodating some movement and misalignment.

5. Metal-Cased Seals These seals provide added durability and resistance to harsh environments. The metal casing protects the sealing lip from external damage, making them ideal for applications where mechanical wear and exposure to harsh chemicals are concerns.

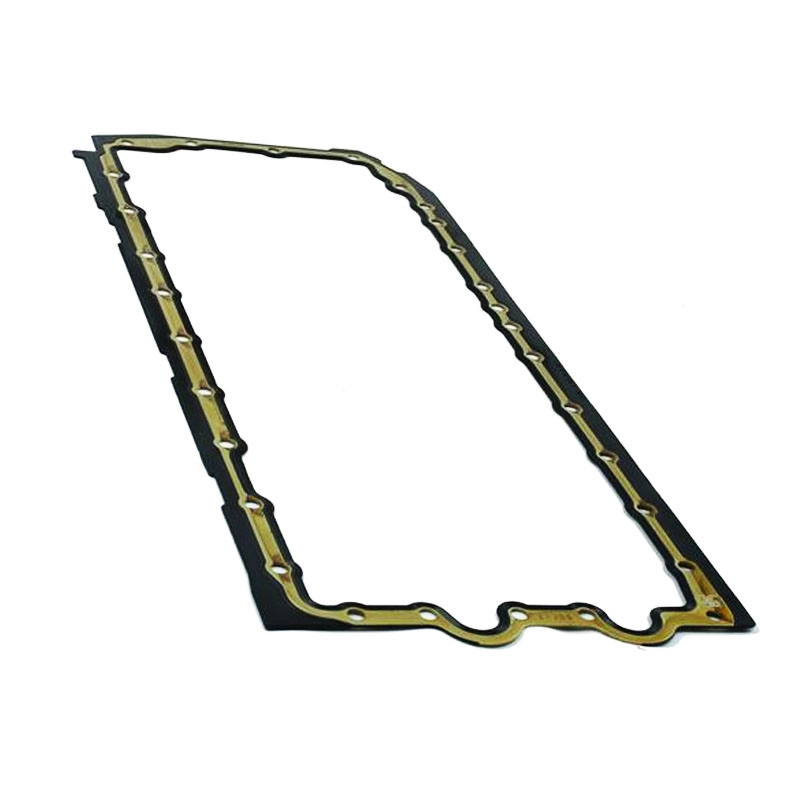

types of oil seals

6. Dual-Lip Seals Designed for applications where there is a risk of contamination or where retaining two different types of fluids is necessary, dual-lip seals feature two lip edges. One lip seals against leakage while the other serves as a barrier against contaminants.

Materials Used in Oil Seals

The materials used in manufacturing oil seals are integral to their performance. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), silicone, and polyurethane. These materials are chosen based on their resistance to temperature fluctuations, chemical environments, and wear. For example, nitrile rubber is widely used due to its good resistance to oils and greases, while fluorocarbon is favored in applications involving extreme temperatures and aggressive chemical substances.

Benefits of Using Oil Seals

1. Leak Prevention Oil seals effectively prevent the leakage of lubricants, which helps maintain the efficiency and effectiveness of machinery over time.

2. Contamination Protection By keeping contaminants like dirt, dust, and moisture out, oil seals prolong the life of bearings and other moving parts.

3. Cost Efficiency Investing in high-quality oil seals can reduce maintenance costs and downtime due to fewer leaks and failures.

4. Versatility With various designs and materials available, oil seals can be tailored to meet the demands of a wide range of applications across industries.

Conclusion

In conclusion, understanding the different types of oil seals is essential for selecting the right seal for a specific application. From rotary seals to static seals and everything in between, each type offers unique advantages that contribute to the overall performance and reliability of mechanical systems. Selecting the appropriate oil seal not only ensures effective sealing but also enhances the durability and lifespan of equipment, driving operational efficiency and cost savings. Whether in automotive, industrial machinery, or any other application, oil seals play a pivotal role in keeping operations running smoothly.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories