stuffing box shaft seal

The Importance of Stuffing Box Shaft Seals in Mechanical Systems

In the world of mechanical engineering, reliability and efficiency are paramount. One of the critical components that contribute to these factors is the stuffing box shaft seal. Often overlooked, this component plays a vital role in preventing leaks and ensuring the smooth operation of various machinery, from pumps to mixers. In this article, we will delve into the construction, functions, and importance of stuffing box shaft seals in mechanical systems.

Understanding the Stuffing Box Shaft Seal

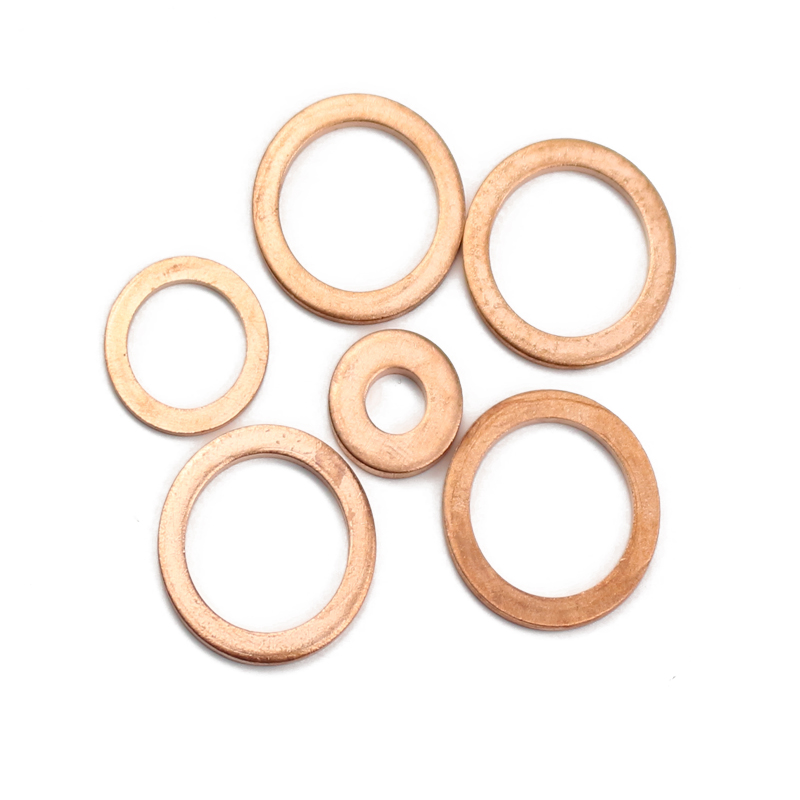

A stuffing box is an enclosure that houses a shaft, allowing it to rotate while minimizing fluid leakage. The stuffing box shaft seal is the mechanism within this enclosure that creates a barrier between the shaft and the environment. It typically consists of packing materials, such as rubber or graphite, which are compressed around the shaft to form a tight seal. In some applications, mechanical seals may replace traditional packing materials for enhanced performance and reduced leakage.

The design of stuffing box shaft seals can vary significantly depending on their application. Standard designs often include a series of packing rings, while newer technologies may utilize advanced materials and constructions to improve durability and reduce friction. This variability allows engineers to select the most appropriate seal for specific operational conditions, including pressure, temperature, and the type of fluid being contained.

Functions of Stuffing Box Shaft Seals

The primary function of stuffing box shaft seals is to prevent the leakage of liquids or gases from the machinery. In processes involving hazardous or corrosive substances, effective sealing is critical to maintaining safety standards and environmental regulations. Moreover, leaks can lead to performance inefficiencies, increasing operational costs and maintenance efforts.

stuffing box shaft seal

Another crucial purpose of the stuffing box shaft seal is to protect the internal components of the equipment. By keeping contaminants such as dirt, dust, and other foreign particles from entering the machinery, the seal helps extend the lifespan of critical parts like bearings and gears. This protective function not only enhances the overall reliability of the equipment but also reduces the likelihood of unexpected failures.

Importance in Industrial Applications

The significance of stuffing box shaft seals becomes evident when considering their applications in various industrial sectors. In the oil and gas industry, for instance, these seals are essential for preventing leaks in drilling equipment and pipelines, where even minor leaks can result in significant environmental damage and financial losses. Similarly, in chemical processing facilities, effective sealing is crucial to operate safely with hazardous materials.

In the water treatment sector, stuffing box shaft seals are employed in pumps to ensure the tight containment of fluids, which is vital for maintaining clean and safe water supplies. Additionally, in food and beverage manufacturing, sanitary stuffing box seals are designed to comply with strict hygiene regulations, ensuring that food products remain uncontaminated.

Conclusion

In conclusion, the stuffing box shaft seal may seem like a small component, but its overall impact on the performance and reliability of mechanical systems is significant. As industries continue to evolve and face new challenges, the importance of effective sealing solutions cannot be overstated. Engineers and technicians must prioritize the selection and maintenance of stuffing box shaft seals to safeguard their operations and enhance the efficiency of their machinery. Through careful consideration of design and materials, the industry can ensure that these critical components continue to meet the demanding needs of modern applications.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories