Understanding the Importance of Pan Gaskets in Ensuring Leak-Free Engine Performance and Maintenance

Understanding Pan Gaskets Function, Importance, and Selection

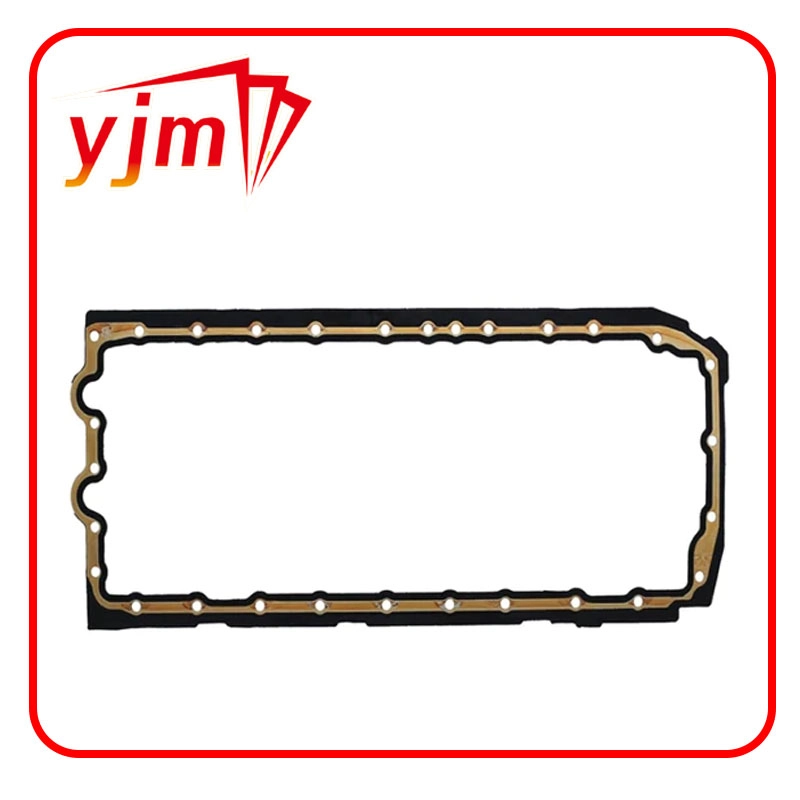

In the world of industrial and mechanical engineering, the term pan gasket refers to a crucial component used to create a seal between two surfaces, typically in engines and various machinery. Gaskets are essential for preventing leaks, maintaining pressure, and ensuring optimal performance in many applications. Among the many types of gaskets available, pan gaskets play a vital role in automotive and aerospace sectors, where precise sealing is critical for functionality and safety.

What is a Pan Gasket?

A pan gasket is specifically designed to fit between the oil pan and the engine block in automotive applications. Its primary purpose is to prevent oil leaks, which can lead to engine damage and reduced efficiency. The oil pan serves as a reservoir for engine oil, and the gasket provides the sealing necessary to contain this oil under varying temperatures and pressures. Typically made from materials such as rubber, cork, or silicon, pan gaskets are engineered to withstand harsh conditions, including exposure to oil, heat, and mechanical stress.

Importance of Pan Gaskets

The importance of pan gaskets cannot be overstated

. A defective or worn-out gasket can lead to catastrophic engine failure, as leaks can cause the engine to run dry of oil, resulting in severe damage. Maintaining an effective seal helps preserve the engine's longevity and performance by ensuring that oil circulates correctly throughout the engine parts. Moreover, a well-functioning pan gasket also plays a role in preventing contaminants from entering the oil reservoir, thereby protecting the engine from wear.In addition to their protective functions, pan gaskets can also contribute to the overall efficiency of an engine. By ensuring that oil remains within the system, they help maintain proper lubrication across moving parts, leading to better fuel efficiency and power output. Consequently, investing in high-quality pan gaskets is a smart decision for anyone looking to optimize engine performance.

pan gasket

Choosing the Right Pan Gasket

Selecting the right pan gasket is essential for effective sealing in any application. Several factors must be considered, including material compatibility, the specific dimensions of the oil pan and engine block, and the operational conditions the gasket will encounter.

1. Material Gaskets can be made from various materials, including rubber, silicone, or cork. Each material has its advantages and disadvantages based on the application's requirements. For instance, silicone gaskets are often preferred for their flexibility and ability to withstand higher temperatures, while cork gaskets might be chosen for their compressibility and ease of installation.

2. Dimensions Gaskets must fit perfectly to ensure an effective seal. Accurate measurements of the oil pan and engine block are crucial when selecting a gasket. An ill-fitting gasket can result in leaks that compromise engine performance.

3. Operational Conditions Consideration of the working environment is necessary. Factors such as temperature fluctuations, exposure to various chemicals, and pressure conditions can dictate the best material and design for the gasket.

Conclusion

In summary, pan gaskets are essential components in mechanical systems, particularly in the automotive industry. Their primary role in preventing oil leaks protects engines from potential damage while contributing to overall performance and efficiency. When choosing a pan gasket, it is vital to consider material, dimensions, and operational conditions to ensure optimal performance and protection. By prioritizing quality and proper selection, engineers and mechanics can significantly enhance the reliability and lifespan of their machinery.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories