Understanding TC Oil Seals and Their Applications in Mechanical Engineering

Understanding TC Oil Seals A Comprehensive Guide

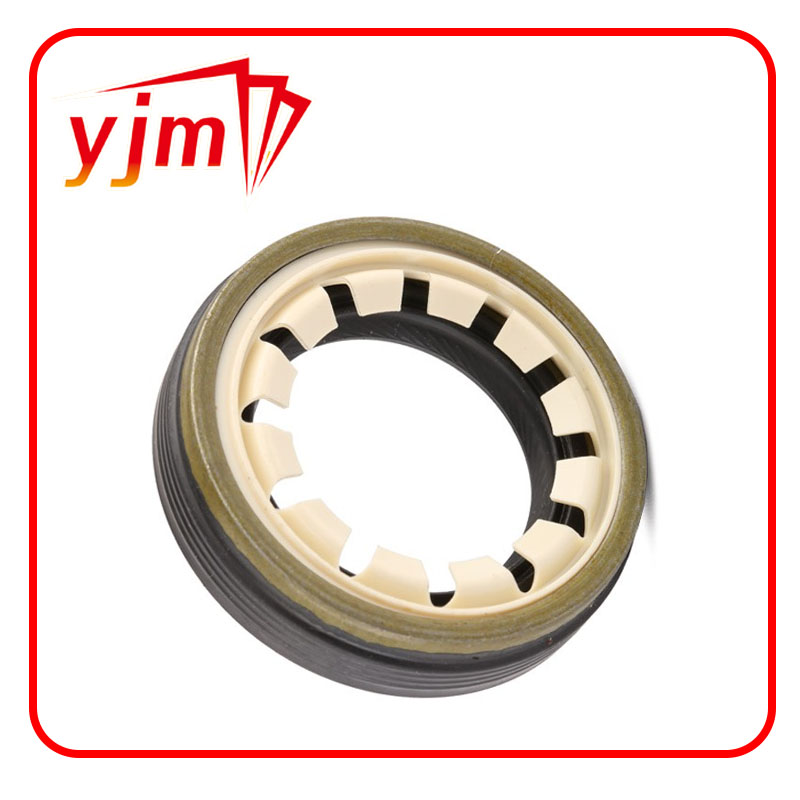

TC oil seals, often referred to as lip seals, play a crucial role in various mechanical systems. These seals are essential in preventing the leakage of lubricating fluids while simultaneously keeping out contaminants, thus ensuring the integrity and longevity of machinery. Their design and material composition allow them to perform effectively in a range of applications, from automotive engines to industrial machinery.

What is a TC Oil Seal?

A TC oil seal typically consists of a circular rubber body with an inner metal casing, which provides added stability. The key feature of a TC seal is its dual lip design. The inner lip creates a tight seal against the shaft, preventing oil from leaking out, while the outer lip helps to keep dirt and moisture from entering the system. This dual-lip configuration makes TC seals highly effective in various environments, particularly where heavy lubrication is required.

Applications of TC Oil Seals

TC oil seals are widely used across multiple industries. In the automotive sector, they are found in engines, transmissions, and differentials, ensuring that oil remains where it should be and protecting crucial components from debris. In industrial applications, TC seals are utilized in pumps, gearboxes, and motors, where they guarantee consistent performance by preventing fluid loss and contamination.

The versatility of TC oil seals extends to various settings, including high-temperature environments, where specialty materials can be employed to withstand extreme conditions. This adaptability allows TC seals to maintain their sealing capabilities in a range of operating temperatures, pressures, and chemical exposures.

tc oil seal

Material Composition

The effectiveness of a TC oil seal is heavily dependent on the materials used in its construction. Typically, they are made from elastomers such as nitrile rubber (NBR), fluorocarbon rubber (FKM), or silicone, which are chosen for their durability and resistance to wear and tear. NBR, for instance, is well-regarded for its oil resistance and versatility, making it a popular choice in automotive applications. Fluorocarbon rubber, on the other hand, excels in high-temperature environments and provides excellent chemical resistance.

Installation and Maintenance

Proper installation of TC oil seals is vital to ensure their effectiveness. Care should be taken to avoid damaging the seal during installation, as any imperfections can lead to premature failure. It is also essential to ensure that the sealing surface is clean and free from debris before the seal is fitted. Regular inspection of the seals should be conducted to identify signs of wear or damage, as this can help avert costly leaks and equipment failures.

Advantages of TC Oil Seals

One of the main advantages of TC oil seals is their ability to provide a reliable barrier against both oils and contaminants. Their dual-lip design enhances their sealing capabilities, making them suitable for demanding applications where conventional seals may fail. Furthermore, the ease of installation and maintenance associated with TC seals makes them a preferred choice for many engineers and technicians.

In summary, TC oil seals are a vital component in ensuring the efficient operation of mechanical systems. Their robust design, coupled with their ability to withstand various conditions, makes them indispensable across many industries. Understanding their features, applications, and maintenance needs can help businesses maximize their equipment's performance and longevity, ultimately leading to increased operational efficiency and reduced downtime. As technology continues to evolve, the design and materials used in TC oil seals are likely to improve, offering even more robust solutions for the challenges of modern machinery.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories