Understanding the Importance of Trailer Axle Grease Seals for Optimal Performance and Maintenance

Understanding Trailer Axle Grease Seals Importance and Maintenance

When it comes to maintaining a trailer, one of the often-overlooked components is the axle grease seal. These seals are a crucial part of the trailer’s functionality, playing a key role in ensuring the longevity and reliability of the axle assembly. In this article, we will delve into the importance of grease seals, how they function, and best practices for their maintenance.

What Are Trailer Axle Grease Seals?

Trailer axle grease seals are mechanical components designed to ensure that the lubricant used in the axle remains intact while preventing contaminants such as dirt, water, and debris from entering the axle assembly. Typically made from rubber or other synthetic materials, grease seals fit snugly around the axle shaft, creating a barrier that safeguards the internal lubrication and components.

Importance of Grease Seals

The primary function of trailer axle grease seals is to maintain the integrity of the grease within the axle. Properly lubricated bearings are essential for reducing friction as the trailer moves, which in turn minimizes wear and tear on the components. If grease leaks out or contaminants infiltrate the axle, it can lead to premature wear, overheating, and ultimately failure of the bearings. This not only poses a safety risk but can also lead to costly repairs and downtime.

Furthermore, grease seals help to maintain the proper load capacity of the trailer. When the lubricant is compromised, the bearings can become damaged, which may lead to improper load distribution and potential failures under weight loads. Thus, ensuring that grease seals are in good condition is essential for safe towing and optimal performance.

Signs of a Failing Grease Seal

Identifying a failing grease seal early can save significant time and money. Common signs include

1. Grease Leakage If you notice grease oozing out from around the axle, this is a clear indication that the seal may be compromised. 2. Wheel Bearing Noise Unusual sounds coming from the wheel area, such as grinding or whining, often suggest that the bearings are not adequately lubricated due to a failing grease seal.

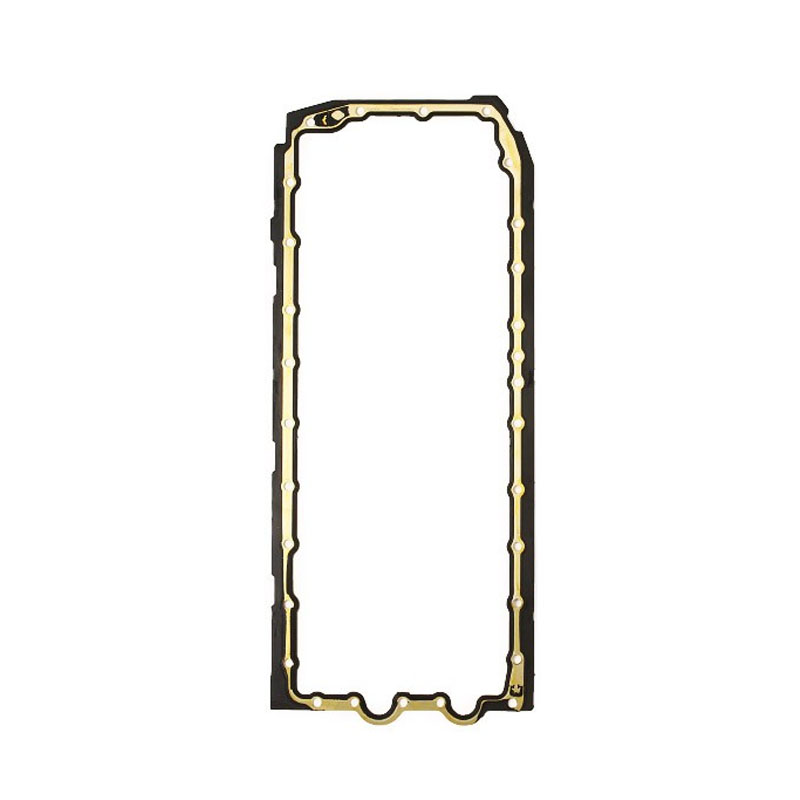

trailer axle grease seals

3. Excessive Heat An increase in temperature in the wheel bearings can occur if there’s a failure in the seal, leading to a lack of lubrication.

Maintenance Tips

Maintaining your trailer axle grease seals is vital for ensuring their longevity and effectiveness. Here are some tips to keep in mind

1. Regular Inspections Periodically check the condition of the grease seals for any signs of wear, leakage, or damage. Regular inspections can help catch issues early on.

2. Grease Application Ensure that the axle is properly greased according to the manufacturer’s specifications. Over-greasing can cause excess pressure on the seals, while under-greasing can lead to inadequate lubrication.

3. Replace When Necessary If you detect any signs of wear or failure, it’s crucial to replace the grease seals immediately. They are relatively inexpensive compared to the potential costs associated with axle damage.

4. Seal Compatibility When replacing seals, ensure that the new seals are compatible with your axle type and sizes. Choosing the wrong type can result in inadequate protection.

In conclusion, trailer axle grease seals are minor components with a significant impact on the overall performance and safety of a trailer. Regular maintenance and timely replacements can prevent costly repairs and ensure that your trailer operates smoothly, safely, and effectively for years to come. By prioritizing the health of your grease seals, you contribute to the longevity and reliability of your trailer system.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories