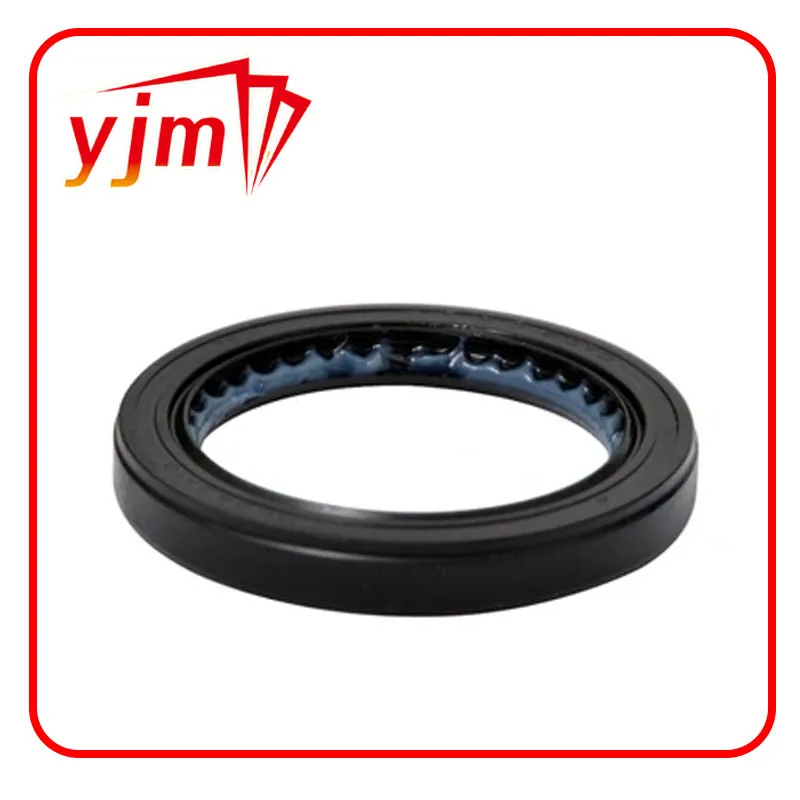

ptfe shaft seal

Understanding PTFE Shaft Seals An Essential Component in Mechanical Systems

PTFE (Polytetrafluoroethylene) shaft seals are an integral part of many mechanical systems, playing a crucial role in maintaining efficiency, reliability, and longevity. These seals are specifically designed to prevent fluid leakage along rotating shafts, which can be vital in various applications ranging from hydrodynamics in pumps to the mechanisms of heavy machinery.

What is PTFE?

PTFE is a synthetic fluoropolymer that is recognized for its remarkable chemical resistance, low friction properties, and ability to withstand extreme temperatures. Commonly known by the brand name Teflon, PTFE is not only non-stick but also significantly durable, making it an ideal choice for seals and gaskets in demanding environments. This material's unique properties offer excellent performance in conditions where other materials may fail, such as high temperatures and aggressive chemicals.

Importance of Shaft Seals

Shaft seals serve multiple purposes in mechanical systems. Their primary function is to prevent the escape of lubricants and other fluids, which is critical for maintaining operational efficiency. Loss of lubrication can lead to increased wear and tear, higher temperatures, and ultimately, mechanical failure. Furthermore, PTFE shaft seals help to keep contaminants, such as dirt and moisture, out of the machinery, thereby prolonging the equipment's lifespan and reducing maintenance costs.

Advantages of PTFE Shaft Seals

1. Chemical Resistance PTFE is resistant to a wide range of chemicals, making it suitable for use in various industries, including pharmaceuticals, food processing, and petrochemicals. This resistance ensures that the seals do not degrade over time, even when exposed to harsh substances.

2. Temperature Tolerance PTFE can handle extreme temperatures, from -200°C to +260°C (-328°F to +500°F). This property makes PTFE shaft seals ideal for high-temperature applications, where traditional rubber seals may fail.

ptfe shaft seal

3. Low Friction The low friction coefficient of PTFE helps in reducing wear on both the seal and the shaft itself. This characteristic minimizes energy loss and enhances the operational efficiency of rotating machinery.

4. Versatility PTFE shaft seals can be manufactured in various shapes and sizes to accommodate different machinery configurations. They can also be engineered to suit specific applications, which contributes to their widespread use.

Applications of PTFE Shaft Seals

The applications of PTFE shaft seals span a diverse range of industries. In the automotive sector, they are used in engines and transmissions to prevent fluid leakage and ensure smooth performance. In the oil and gas industry, they help in sealing rotating shafts in pumps and compressors, critical for transporting fluids safely and efficiently. Additionally, PTFE shaft seals are widely utilized in aerospace, food and beverage manufacturing, and chemical processing industries due to their robustness and reliability.

Installation and Maintenance Considerations

While PTFE shaft seals are designed for durability, proper installation is essential to ensure their effectiveness. Misalignment or incorrect fitting can lead to premature failure, resulting in potential operational disruptions. Regular maintenance checks should be performed to assess the condition of the seals, particularly in high-wear applications.

Conclusion

In conclusion, PTFE shaft seals are a vital component in many mechanical systems, providing essential protection against fluid leakage while offering a range of benefits such as chemical resistance, temperature stability, and low friction. Their versatility allows for application across numerous industries, making them indispensable in modern machinery. Investing in high-quality PTFE shaft seals can lead to enhanced performance, reduced maintenance costs, and prolonged equipment life, ultimately contributing to greater operational efficiency and productivity.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories