Exploring the Benefits of Oil Stem Seals in Mechanical Applications

Understanding Oil Stem Seals Importance and Functionality in Machinery

Oil stem seals are essential components used in various machinery, particularly in engines and other systems where fluid containment is crucial. These seals play a significant role in maintaining the integrity of sealing systems, preventing leakage of lubricants and fluids, and ensuring optimal performance of mechanical systems. Their importance cannot be overstated, as they contribute not only to the efficiency of the machinery but also to the longevity and reliability of the components they protect.

At its core, an oil stem seal is a barrier designed to prevent the escape of lubricants and the ingress of contaminants. In engines, for instance, these seals are strategically installed around the stem of valves and other moving parts. Their primary function is to retain oil within the engine while minimizing the flow of oil into the combustion chamber. This is critical, as excessive oil entering the combustion area can lead to increased emissions, reduced fuel efficiency, and potential engine damage.

The design and material composition of oil stem seals significantly influence their performance. Typically made from elastomers, such as nitrile rubber or fluorinated rubber, these seals provide excellent resistance to heat, oil, and chemical exposure. The design often includes a lip that compresses against the shaft or the housing, creating the necessary snug fit to prevent leaks. Depending on the application, manufacturers may also incorporate features such as reinforcement layers for increased durability and longevity.

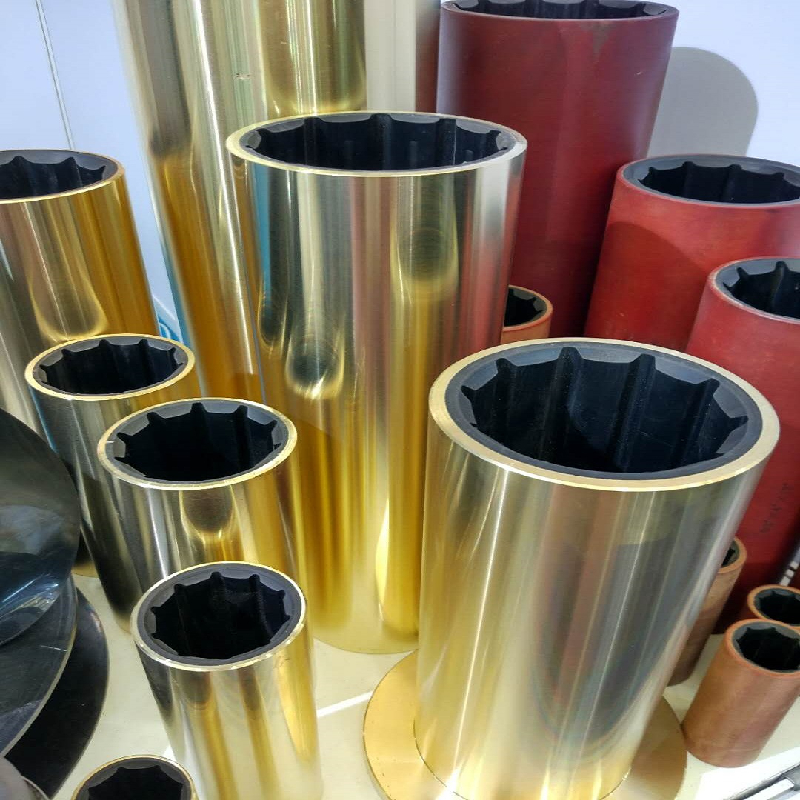

oil stem seals

Proper installation of oil stem seals is paramount

. Even a slight misalignment or inadequate seating during installation can lead to premature failure, resulting in oil leaks and potential damage to the machine. Special attention must also be given to the condition of the sealing surfaces; any wear or pitting could compromise the seal's effectiveness. Regular maintenance and inspections can help identify issues early, ensuring the seals operate efficiently throughout the machinery's lifespan.One of the most significant advantages of using high-quality oil stem seals is their ability to enhance the overall performance of the machinery. By effectively containing the oil and minimizing leaks, these seals help maintain optimal lubrication within the system. This results in reduced wear on moving parts, better heat dissipation, and ultimately improved efficiency. Machinery that operates smoothly and efficiently not only extends its operational life but also reduces downtime and maintenance costs.

Another critical aspect of oil stem seals is their environmental impact. Any leakage from machinery can lead to oil spills, which are detrimental to the environment. By utilizing reliable oil stem seals, manufacturers can significantly mitigate the risk of leaks, contributing to more sustainable and environmentally friendly operations. This is particularly important in industries that deal with hazardous materials or operate in sensitive environments where contamination can have severe consequences.

In conclusion, oil stem seals are vital components in any machinery that relies on fluid containment and lubrication. Their functionality directly impacts the performance, reliability, and longevity of mechanical systems. Investing in high-quality seals, ensuring proper installation, and conducting regular maintenance can lead to substantial benefits for manufacturers and operators alike. As industries continue to prioritize efficiency and environmental responsibility, the role of oil stem seals will remain prominent, making them a critical consideration in modern machinery design and maintenance strategies.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories