Understanding Crankshaft Main Oil Seal Function and Importance in Engine Performance

Understanding the Crankshaft Main Oil Seal

The crankshaft main oil seal is a crucial component in an internal combustion engine. Located at the point where the crankshaft exits the engine block, this seal performs the essential function of preventing engine oil from leaking out while keeping contaminants from entering the engine. This task is vital to maintaining optimal engine performance and longevity. To understand better the role and significance of the crankshaft main oil seal, let’s delve into its functions, construction, common issues, and maintenance practices.

Functions of the Crankshaft Main Oil Seal

The primary role of the crankshaft main oil seal is to retain oil within the oil sump and ensure it lubricates the moving parts of the engine effectively. This lubrication is critical because it minimizes friction between the crankshaft and other components, such as the bearings and connecting rods. By keeping the oil contained, the seal prevents the loss of lubricating oil, which could lead to severe engine damage due to inadequate lubrication.

Additionally, the crankshaft main oil seal acts as a barrier against dirt, dust, and other contaminants that may damage the engine internals. Any foreign particles that enter the engine can cause wear and tear, reducing its lifespan and performance. Thus, the oil seal not only retains oil but also protects the engine from harmful external elements.

Construction and Materials

Modern crankshaft main oil seals are typically constructed from durable rubber compounds that are resistant to oil, temperature fluctuations, and wear. The most common types of materials used include nitrile, fluorocarbon, and silicone. Each of these materials brings specific benefits, such as enhanced heat resistance or improved sealing capabilities.

The design of the seal usually includes a metal or rubber outer casing that fits tightly into the crankcase. The inner part of the seal contains a lip that makes contact with the crankshaft. This contact creates a tight seal, ensuring minimal oil leakage while allowing the crankshaft to rotate freely. The design and material choices help to ensure a long service life, but like any engine component, they can eventually wear out.

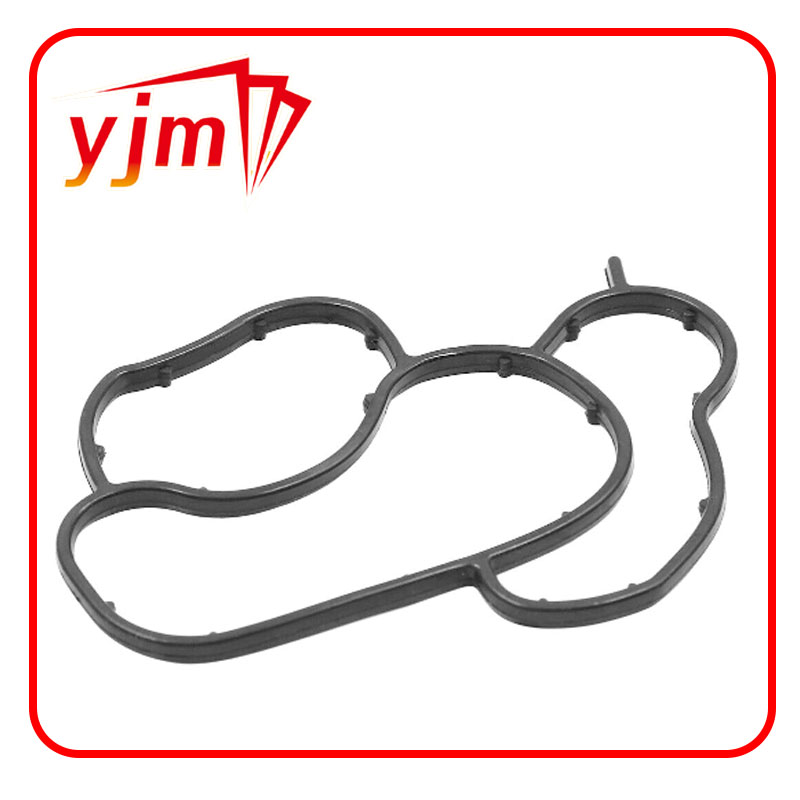

crankshaft main oil seal

Common Issues

Over time, crankshaft main oil seals can develop problems due to wear, tear, and environmental factors. One common issue is oil leakage, which can lead to low oil levels and engine overheating. If an oil seal fails, drivers might notice oil spots beneath the vehicle or a drop in oil pressure.

Another problem can occur if the seal becomes contaminated with dirt or abrasive materials. This contamination can cause the seal to wear more quickly, leading to premature failure. It is also essential to ensure that the crankshaft is properly aligned; misalignment can stress the seal and lead to a failure.

Maintenance Practices

Regular maintenance can prolong the life of the crankshaft main oil seal and the engine. Routine oil changes help minimize contaminants in the oil that can wear down the seal. Additionally, checking for any signs of oil leaks during regular inspections can help catch problems early before they lead to more significant issues.

It’s also essential to use high-quality oils and ensure the oil level is within the recommended range. Engine misalignment should be addressed promptly, ideally during routine mechanical inspections.

In conclusion, the crankshaft main oil seal is a small but vital component in ensuring the smooth operation and longevity of an internal combustion engine. By preventing oil leaks and protecting against contamination, it plays a crucial role in maintaining engine health. Regular checks and proper maintenance can help avoid common issues and ensure the engine runs efficiently for years to come.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories