Choosing the Right Flat Ring Seal for Optimal Performance and Durability

Understanding Flat Ring Seals Design, Applications, and Advantages

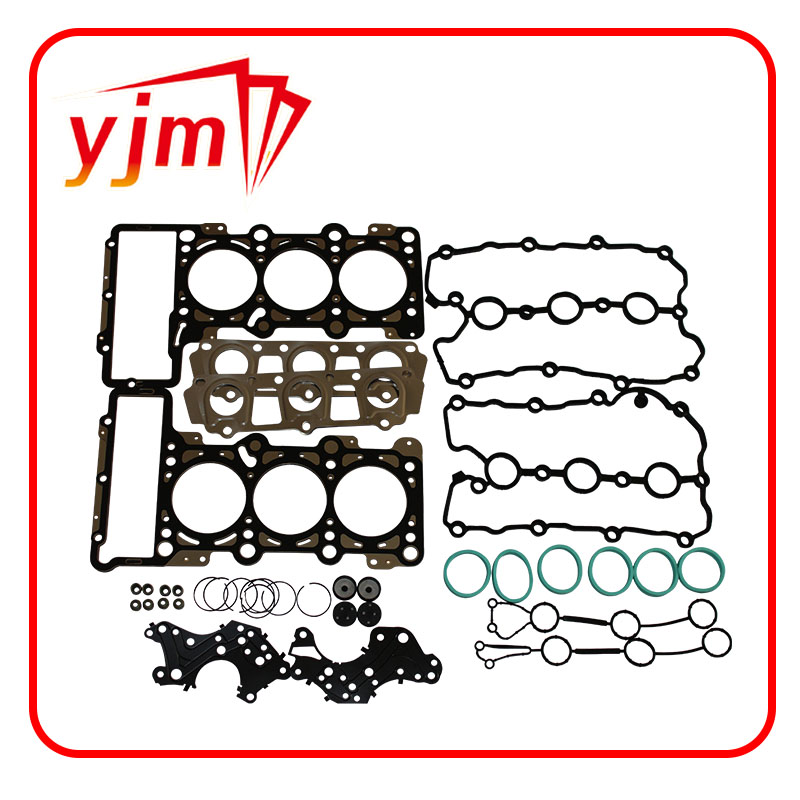

Flat ring seals, also known as flat gaskets or sealing rings, are essential components in various industrial applications. These seals provide a reliable barrier against the leakage of fluids and gases, ensuring the integrity and safety of equipment and systems. In this article, we will explore the design, applications, and advantages of flat ring seals, highlighting their importance in modern engineering.

Design and Materials

Flat ring seals are typically fabricated from a variety of materials, including rubber, silicone, neoprene, and various plastics, depending on the specific requirements of the application. The choice of material is crucial, as it directly influences the seal's performance, durability, and resistance to specific substances. For instance, in applications where high temperatures or aggressive chemicals are involved, materials like fluorocarbon elastomers or high-temperature silicone may be employed.

The design of a flat ring seal is relatively simple, usually comprising a circular shape with a consistent thickness. This design allows the seal to compress easily when positioned between mating surfaces, forming a tight seal. The effectiveness of the seal is largely dependent on the compression set of the material, which refers to its ability to return to its original shape after being deformed. A lower compression set ensures a longer-lasting seal and reduces the risk of leaks.

Applications

Flat ring seals are utilized in a myriad of applications across various industries, including automotive, aerospace, manufacturing, and plumbing. In the automotive sector, flat ring seals are commonly found in engines, transmissions, and other components where preventing fluid leakage is critical. They ensure that oil, coolant, and fuel systems operate efficiently without any loss of essential fluids.

In the aerospace industry, where safety and reliability are paramount, flat ring seals play a vital role in fuel systems, hydraulic systems, and environmental control systems. Their ability to withstand extreme temperatures and pressures makes them ideal for use in aircraft where failure is not an option.

flat ring seal

Manufacturing processes, particularly those involving hydraulic systems, also rely on flat ring seals. They provide a smooth and effective sealing solution that can accommodate various pressures and temperatures, protecting machinery and enhancing efficiency. Similarly, in plumbing applications, flat ring seals are employed to prevent leaks in pipes and fittings, ensuring the functional integrity of water supply systems.

Advantages of Flat Ring Seals

One of the significant advantages of flat ring seals is their versatility. They can be produced in numerous sizes and materials, making them suitable for a wide range of applications. This adaptability allows engineers and designers to select the most appropriate seal for specific operating conditions.

Another benefit is their relatively straightforward installation process. Flat ring seals can be easily placed between two flat surfaces, require minimal tools, and often do not necessitate any special skills for installation. This ease of use translates to reduced labor costs and shorter assembly times in manufacturing and maintenance operations.

Flat ring seals also offer excellent sealing capabilities when properly designed and installed. They can effectively compress to fill gaps between surfaces, which helps to prevent leaks. Additionally, their resistance to various chemicals, extreme temperatures, and pressures ensures longevity and reliability, reducing the frequency of replacements and maintenance.

Conclusion

In summary, flat ring seals are integral to many industrial applications, providing essential sealing capabilities that enhance the safety and efficiency of equipment. Their versatile design, ease of installation, and reliable performance make them a preferred choice across multiple industries. As technology advances, the development of new materials and designs will further enhance the performance of flat ring seals, solidifying their role in modern engineering and manufacturing processes. Understanding the importance of these components is essential for engineers and technicians working to maintain and improve industrial systems.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories