Understanding Boat Trailer Axle Seals for Optimal Performance and Longevity

Understanding Boat Trailer Axle Seals A Guide for Boat Owners

When it comes to boating, ensuring that your vessel is well-maintained is crucial for both performance and safety. One often-overlooked aspect of boat maintenance is the condition of the trailer, specifically the axle seals. These small components play a significant role in the functionality of your boat trailer. This article will explore what axle seals are, their importance, common problems, and maintenance tips to keep your boat trailer in top condition.

What Are Axle Seals?

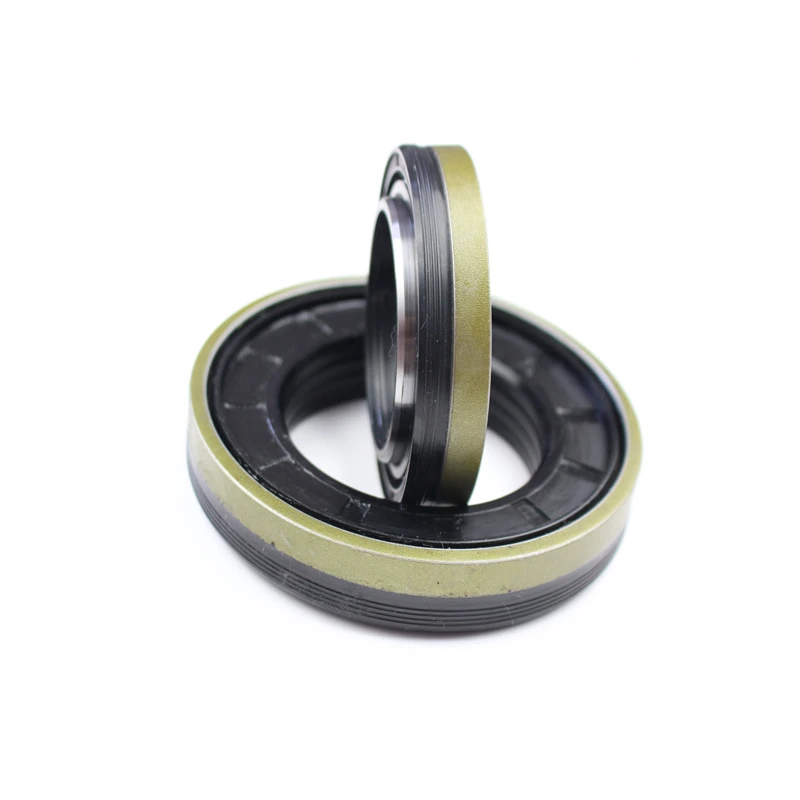

Axle seals are circular rings typically made from rubber or synthetic materials, positioned at the ends of the trailer's axles. Their primary function is to prevent water, dirt, and other contaminants from entering the axle assembly while also retaining the lubricant within. This fluid is essential for reducing friction and heat within the axle, ensuring smooth operations and extending the lifespan of the trailer.

Why Are Axle Seals Important?

The significance of axle seals cannot be overstated. When functioning correctly, they safeguard the internal components of the axle from environmental factors. Here are a few reasons why good axle seals are vital

1. Prevention of Contamination Water and dirt can cause severe damage to bearings and other critical components, leading to premature wear and failure.

2. Lubrication Retention The lubricant within the axle plays a key role in reducing friction. Protecting it from spilling out or getting contaminated is essential for the proper functioning of the axle.

3. Safety A compromised axle due to a faulty seal can lead to complete axle failure while on the road, posing a significant safety hazard for both you and fellow road users.

Common Problems with Axle Seals

Over time, axle seals can wear down or become damaged. Here are some common issues to watch out for

boat trailer axle seals

2. Oil Leaks A clear sign of a failing axle seal is the presence of oil puddling under the trailer. This indicates that the lubricant is escaping, which could lead to significant damage if not addressed promptly.

3. Noise Grinding or humming noises coming from the axle area can indicate that the bearings are not receiving adequate lubrication, often due to a failing seal.

Maintenance Tips

Maintaining your boat trailer’s axle seals is crucial for a trouble-free experience. Here are some maintenance tips to keep in mind

1. Regular Inspections Conduct routine checks of the axle seals during each pre-launch inspection. Look for signs of wear, cracking, or leaks.

2. Cleaning After every use, especially in saltwater, rinse the trailer thoroughly. This helps remove salt and debris that can accelerate seal degradation.

3. Lubrication Follow manufacturer guidelines for the appropriate type and frequency of lubrication. Regularly check the lubricant level and refill as necessary.

4. Professional Servicing When in doubt, seek professional help. If you suspect a seal failure or notice unusual noises, it’s best to have a mechanic examine the trailer.

5. Replacement If a seal is cracked or leaking, replace it immediately. It's a small investment compared to the potential costs of axle repairs or replacements.

Conclusion

Boat trailer axle seals may be small components, but they play a significant role in the overall functionality and safety of your trailer. Proper maintenance and timely replacement are essential to avoiding costly repairs and ensuring a safe boating experience. By keeping an eye on these vital components, boat owners can enjoy peace of mind knowing their trailer—and their precious cargo—are well protected on the road. Remember, a well-maintained trailer is just as important as maintaining the boat itself. Happy boating!

-

Understanding Polaris Front Differentials: Key Components for Off-Road Performance

News Jun.20,2025

-

Understanding Crankshaft Seals and Gaskets: Essential Components for Engine Longevity

News Jun.20,2025

-

Understanding Crankshaft Oil Seals: Vital Protection for Engine Performance

News Jun.20,2025

-

The Vital Role of Front and Rear Crankshaft Seals in Engine Protection

News Jun.20,2025

-

Rear Crankshaft Seals: Protecting Your Engine from the Back End

News Jun.20,2025

-

Crank Oil Seals: What They Do, How They Fail, and What They Cost

News Jun.20,2025

-

Understanding Oil Crush Washers: A Small Component with a Big Role in Vehicle Maintenance

News Jun.19,2025

Products categories