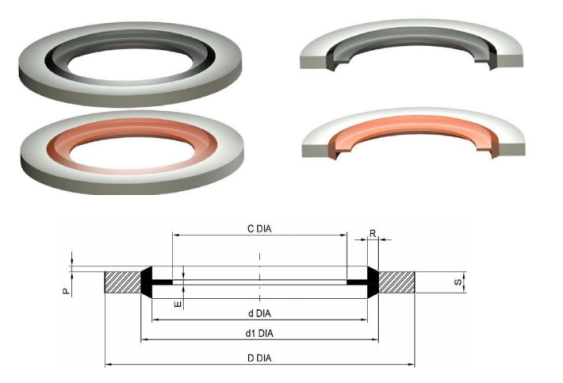

Oil seal for various applications, available in 25%, 40%, and 70% variants

Oil seals are essential components in many mechanical systems, serving to prevent leakage of oil or other fluids. They are commonly used in engines, gearboxes, hydraulic systems, and various other applications. The quality and performance of an oil seal can greatly impact the efficiency and longevity of a machine or system.

When considering oil seals, two key factors to take into account are the material they are made from and their design. The material of an oil seal should be chosen based on the specific requirements of the application. Common materials used for oil seals include rubber, silicone, and polyurethane. Each material has its own strengths and weaknesses, so it is important to select the most suitable one for the intended use.

.

In terms of sealing efficiency, the percentage of oil seal is an important consideration. A higher percentage of oil seal means that the seal has a greater ability to prevent oil leakage. For example, a 25% oil seal indicates that the seal is capable of blocking 25% of oil leakage, while a 40% oil seal can prevent 40% of leakage. A 7% oil seal, on the other hand, may not be as effective at preventing leakage compared to higher percentage seals.

25 40 7 oil seal

It is important to select the appropriate oil seal percentage based on the specific requirements of the application. For high-pressure systems or applications where oil leakage could lead to serious consequences, a higher percentage oil seal may be necessary to ensure optimal performance. On the other hand, for less critical applications, a lower percentage oil seal may be sufficient.

Proper installation and maintenance of oil seals are also critical for ensuring their effectiveness. Improper installation can lead to seal damage or premature failure, while lack of maintenance can result in seal deterioration over time. Regular inspection and replacement of worn or damaged oil seals are essential for maintaining the efficiency and reliability of mechanical systems.

In conclusion, oil seals play a crucial role in preventing oil leakage in mechanical systems. The material, design, and percentage of oil seal are all important factors to consider when selecting a seal for a specific application. By choosing the right oil seal and ensuring proper installation and maintenance, the efficiency and longevity of machines and systems can be greatly improved.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories