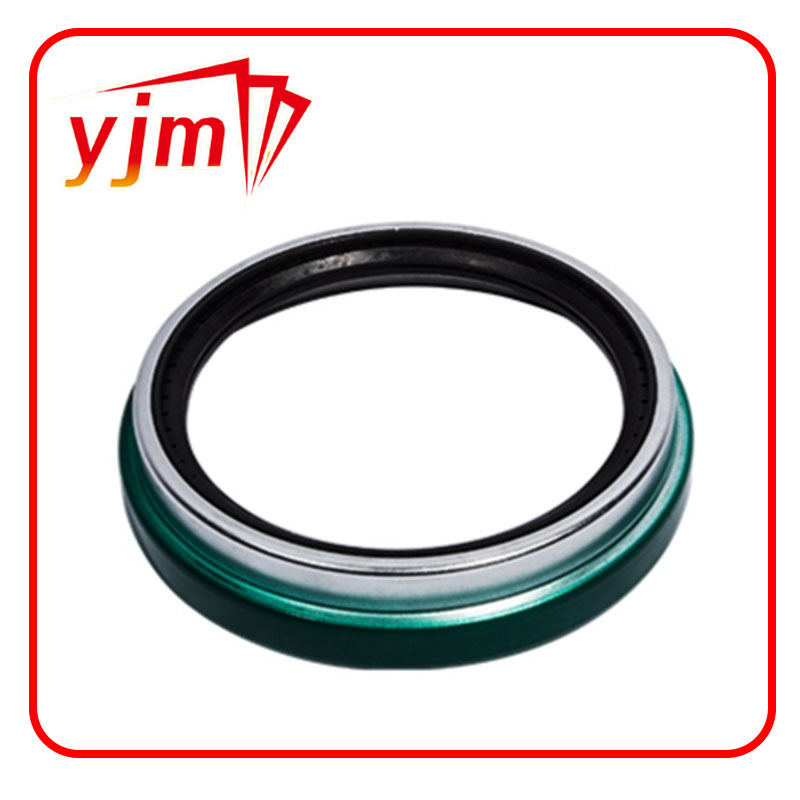

shaft seal differential

Understanding Shaft Seal Differential Functions, Types, and Applications

A shaft seal differential plays a crucial role in various mechanical systems, particularly in vehicles and industrial machinery. Understanding its purpose, types, and applications can shed light on how it contributes to the efficient functioning and longevity of equipment. This article delves into these aspects, offering insights into the importance of shaft seal differentials.

What is a Shaft Seal Differential?

At its core, a shaft seal differential is designed to prevent the leakage of fluids from the differential housing. The differential itself is a complex mechanical component that allows for the differences in wheel speed between the left and right sides of an axle, essential for smooth turning and enhanced vehicle handling. As gears within the differential operate, they require lubrication to function effectively. This is where the shaft seal comes in; it ensures that the lubricating oil remains contained within the differential, thus maintaining optimal operation.

Functions of Shaft Seal Differentials

The primary function of a shaft seal differential is to maintain the integrity of the lubrication system within the differential. By preventing leaks, it ensures that the lubricant's properties remain intact, protecting the gears from wear and potential damage. Additionally, it inhibits the ingress of contaminants such as dirt, moisture, and debris, which can adversely affect the performance and lifespan of the gears.

Another important function of the shaft seal is to control the internal pressure within the differential housing. As the differential operates, it generates heat, which can lead to the expansion of gases. A properly functioning seal allows for this gas to escape while preventing lubricants from seeping out, maintaining balance within the system.

Types of Shaft Seals

There are several types of shaft seals used in differential applications, each with its unique characteristics and advantages

shaft seal differential

1. Lip Seals Comprising elastomeric materials, lip seals are one of the most common seals used in differential setups. They feature a flexible lip that presses against the shaft, effectively creating a seal that withstands high pressures and temperatures.

2. Radial Seals These seals are designed to handle rotational movement and are often used in high-speed applications. They provide an effective barrier against fluid loss and contamination.

3. Mechanical Seals These are utilized in applications requiring very high-pressure retention. They consist of two surfaces that are pressed together to prevent leakage, making them ideal for heavy-duty differential applications.

4. Sponge Seals Made from flexible foam-like materials, sponge seals can adapt to various shaft sizes and provide a good anti-leak barrier, albeit generally suited for lower pressure applications.

Applications of Shaft Seal Differentials

Shaft seal differentials are extensively used in the automotive industry, particularly in the drive systems of cars, trucks, and motorcycles. They are critical in minimizing maintenance costs by reducing the likelihood of fluid leaks, which can lead to significant damage and expensive repairs.

In industrial applications, these seals are vital in machinery such as gearboxes, pumps, and conveyors. Their ability to maintain lubrication integrity and protect internal components from external contaminants is essential for the smooth operation and longevity of industrial equipment.

Conclusion

In summary, shaft seal differentials are essential components in both automotive and industrial applications. They serve the critical function of preventing fluid leaks and protecting internal mechanisms from contaminants. By understanding the different types of shaft seals and their applications, users can appreciate their importance in ensuring efficient operation and prolonging the lifespan of mechanical systems. Proper maintenance and timely replacement of these seals are vital in preserving the overall health of the differential, highlighting their significance in engineering design and application.

-

The Ultimate Guide to Building a Car Repair Kit Every Driver Should Own

News May.09,2025

-

The Essential Guide to Oil Filter Gaskets and Housings in Engine Maintenance

News May.09,2025

-

The Complete Guide to Oil Pan Gaskets for Honda B-Series and Automatic Transmissions

News May.09,2025

-

How to Identify and Repair Oil Housing Gasket and Seal Leaks

News May.09,2025

-

Everything You Need to Know About Oil Pan Gaskets and Replacements

News May.09,2025

-

Everything You Need to Know About Changing Oil Filter and Adapter Gaskets

News May.09,2025

-

Understanding Marine Bearings: The Key to Smooth Sailing and Safe Trailering

News May.08,2025

Products categories