Rectangular O-Rings - Durable Sealing Solutions for Various Applications

Understanding Rectangular O-Rings Applications and Advantages

Rectangular O-rings, although less common than their circular counterparts, have garnered attention in various industrial applications due to their unique properties and advantages. These specialized sealing components introduce a new dimension to sealing technology, providing innovative solutions for maintaining integrity in various systems.

Design and Characteristics

The primary characteristic of a rectangular O-ring is its cross-sectional shape, which is a rectangle. This design allows for a larger contact area with surfaces, leading to enhanced sealing capabilities. The rectangular shape also permits the creation of tighter seals in certain environments, compensating for misalignments and variations in surface flatness that circular O-rings might not address as effectively.

The materials used to manufacture rectangular O-rings are similar to those employed for traditional O-rings, including rubber, silicone, and various elastomers. These materials are chosen based on the application’s specific requirements, such as temperature resistance, chemical compatibility, and mechanical strength.

Applications

Rectangular O-rings are utilized in various sectors, including automotive, aerospace, manufacturing, and automation. In the automotive industry, for instance, they are often found in hydraulic systems and fuel dampers, where minimizing leaks is critical. In aerospace applications, these rings are used in pressure seals on various components where airtight integrity is paramount.

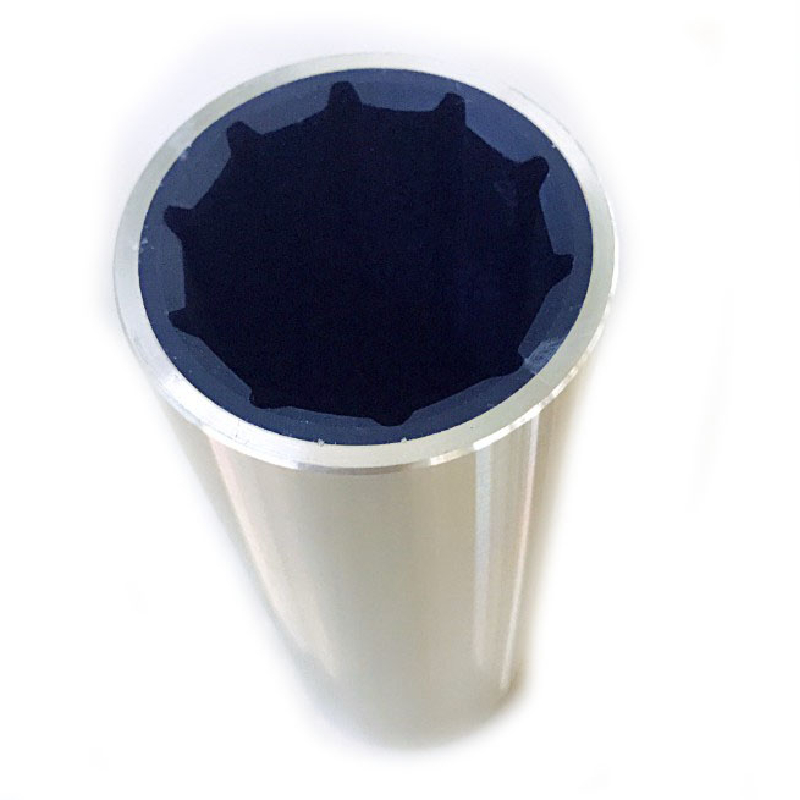

rectangular o ring

Additionally, in the realm of manufacturing and automation, rectangular O-rings play a vital role in creating reliable seals in pneumatic and hydraulic cylinders. Their design helps accommodate better fluid dynamics, leading to improved efficiency and performance in machinery.

Advantages

One of the major advantages of rectangular O-rings is their ability to perform well in high-pressure environments. Due to their larger contact area, they can withstand pressure variations without compromising the seal. This quality is particularly advantageous in hydraulic applications, where maintaining optimal pressure is essential for operational efficiency.

Moreover, rectangular O-rings often result in reduced wear on sealing surfaces. Their shape allows for an even distribution of stress, minimizing the likelihood of deformation. This longevity not only contributes to lower maintenance costs but also enhances the overall safety of the systems in which they are employed.

Conclusion

In conclusion, while rectangular O-rings may not be as widely recognized as their circular versions, they represent a significant advancement in sealing technology. Their unique design, coupled with the right materials, provides solutions that cater to specific sealing challenges across various industries. As engineering challenges evolve and demand for more specialized components increases, rectangular O-rings are poised to play a crucial role in ensuring the efficiency and reliability of modern machinery and systems. Embracing such innovative solutions will ultimately lead to better performance, safety, and reduced operational costs in many applications.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories