Exploring Different Types of Oil Seals A Comprehensive Guide

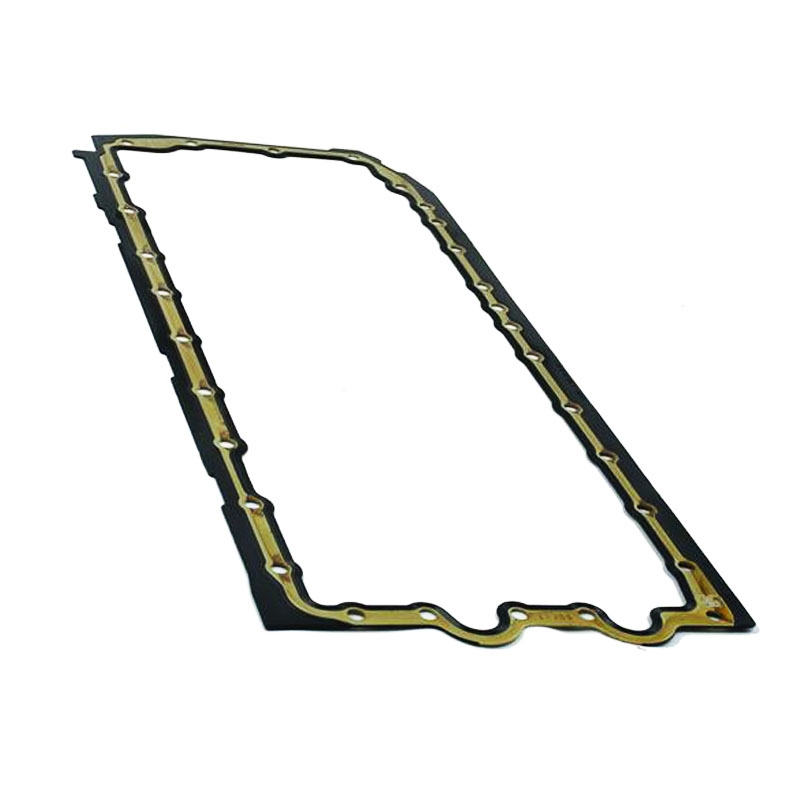

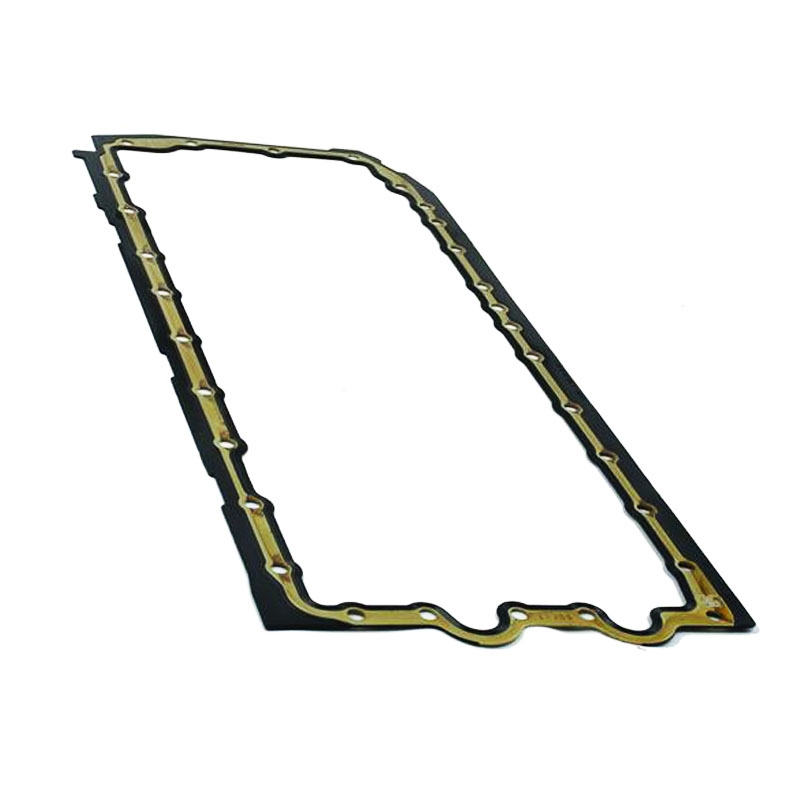

They rely on the tight fit between mating metal surfaces to prevent fluid leakage They rely on the tight fit between mating metal surfaces to prevent fluid leakage

They rely on the tight fit between mating metal surfaces to prevent fluid leakage They rely on the tight fit between mating metal surfaces to prevent fluid leakage oil seal types pdf. These seals are commonly found in aerospace and nuclear industries where high-performance and reliability are paramount.

V-ring seals, also known as scraper seals, are shaped like a V and are installed with the point facing the direction of rotation. They primarily function to remove dirt and debris from the shaft while also preventing oil leakage. They are commonly used in agricultural and construction equipment.

Lastly, we have magnetic seals, which utilize the property of magnetism to hold the sealing element in place. They are particularly useful in applications where contamination control is critical, such as in the chemical and pharmaceutical industries.

Understanding the nuances of these oil seal types is crucial for selecting the right seal for a specific application. Factors such as operating conditions, temperature range, pressure, and speed all influence the choice. A well-chosen oil seal can significantly enhance the performance and lifespan of any mechanical system.

In conclusion, oil seals are the unsung heroes of engineering, silently ensuring the smooth functioning of our machines. Their diversity in design and functionality underscores the importance of selecting the correct seal for each unique application. The next time you encounter a 'oil seal types PDF', remember, it's not just a document; it's a blueprint for maintaining the heart of your machinery.

oil seal types pdf. These seals are commonly found in aerospace and nuclear industries where high-performance and reliability are paramount.

V-ring seals, also known as scraper seals, are shaped like a V and are installed with the point facing the direction of rotation. They primarily function to remove dirt and debris from the shaft while also preventing oil leakage. They are commonly used in agricultural and construction equipment.

Lastly, we have magnetic seals, which utilize the property of magnetism to hold the sealing element in place. They are particularly useful in applications where contamination control is critical, such as in the chemical and pharmaceutical industries.

Understanding the nuances of these oil seal types is crucial for selecting the right seal for a specific application. Factors such as operating conditions, temperature range, pressure, and speed all influence the choice. A well-chosen oil seal can significantly enhance the performance and lifespan of any mechanical system.

In conclusion, oil seals are the unsung heroes of engineering, silently ensuring the smooth functioning of our machines. Their diversity in design and functionality underscores the importance of selecting the correct seal for each unique application. The next time you encounter a 'oil seal types PDF', remember, it's not just a document; it's a blueprint for maintaining the heart of your machinery. -

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories