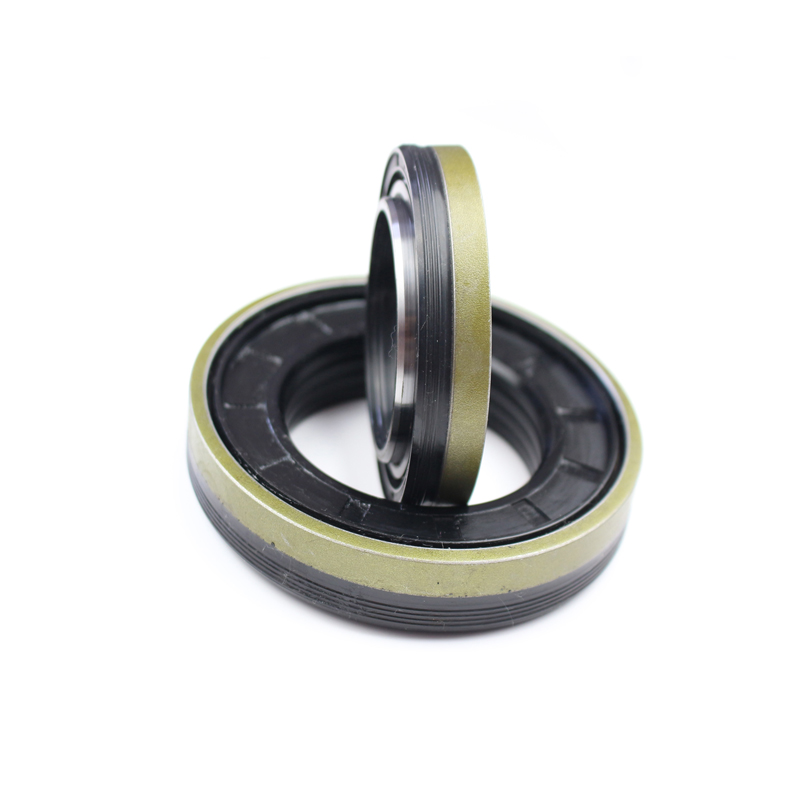

oil lip seals

Understanding Oil Lip Seals Essential Components in Mechanical Engineering

Oil lip seals, also known as shaft seals or radial seals, play a critical role in various mechanical systems by preventing the leakage of lubricants while keeping contaminants out. These seals are predominantly used in rotary applications where rotating shafts require protection against external dirt, dust, and moisture, as well as internal oil loss.

The design of oil lip seals typically features a flexible lip that makes contact with the shaft, forming a barrier that minimizes the escape of lubricant. The lip is usually made of elastomeric materials, which provide the necessary flexibility and resilience. Common materials used for lip seals include rubber, such as nitrile (NBR) and fluorocarbon (FKM), each having different temperature and chemical resistance properties.

One of the primary functions of oil lip seals is to retain oils and lubricants within a system. Without these seals, lubricants could easily escape, leading to increased friction, overheating, and ultimately, premature wear or failure of mechanical components. For instance, in automotive applications, oil lip seals are crucial in engines and transmissions. They ensure that the oil remains where it is needed, facilitating efficient operation and extending the lifespan of the components.

Another significant function is protecting mechanical systems from contaminants. Oil lip seals act as a barrier, preventing dirt, water, and other potentially harmful materials from entering critical areas. This is particularly important in environments exposed to harsh conditions, such as construction sites or industrial applications where machinery is often subjected to grime and moisture. A reliable seal ensures that the internal components remain clean and functional.

oil lip seals

When selecting the appropriate oil lip seal for a particular application, several factors must be considered. These include the shaft diameter, operating temperature range, the type of lubricant used, and the environmental conditions the seal will be exposed to. Additionally, the speed at which the shaft rotates can affect seal performance. High speed can generate heat, impacting the seal’s durability and effectiveness.

Installation of oil lip seals is also a crucial aspect of their performance. Proper alignment and fit are essential to achieving a good seal and preventing premature failure. If the seal is installed incorrectly, it may lead to leakage or damage, which can cause significant disruptions in machinery operation. Therefore, it is vital to follow manufacturer guidelines and recommendations during installation.

In terms of maintenance, oil lip seals are generally low-maintenance components. However, periodic inspections are beneficial to identify any signs of wear or damage. It is not uncommon for seals to degrade over time due to factors such as temperature fluctuations, chemical exposure, and mechanical wear. Early detection of issues allows for timely replacements, helping to prevent more significant problems down the line.

In conclusion, oil lip seals are indispensable elements in mechanical engineering that serve to retain lubricants and block contaminants. Their design and material choices are integral to their performance in various environments. Understanding the role oil lip seals play, along with their installation and maintenance, is vital for ensuring the reliability and efficiency of mechanical systems. As industries continue to evolve, the importance of high-quality seals will remain paramount in safeguarding machinery and optimizing operational longevity. Whether in automotive applications or heavy machinery, oil lip seals are essential to the seamless functioning of countless mechanical systems.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories